What Is EPC in Solar? The Complete Turnkey Solution

EPC (Engineering, Procurement, Construction) is the backbone of successful solar projects. This integrated approach delivers solar installations through three critical phases:

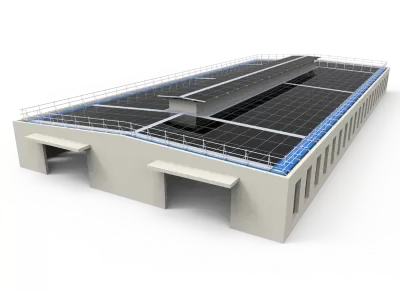

Engineering: Precision Solar Design

Our engineers leverage BIM technology and 100+ patents to optimize layouts for maximum yield. The process includes wind tunnel validation and site-specific structural analysis, particularly crucial for projects using our GS-Smart Ground Mounting System.

Procurement: Global Supply Chain Excellence

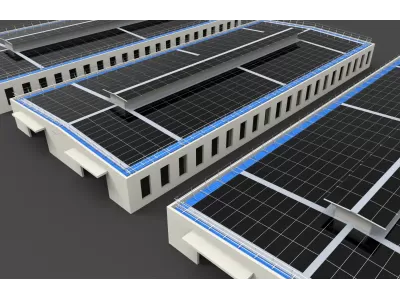

With a 110,000m² production facility and UL/TUV-certified components, we ensure on-time delivery. Our components division maintains inventory for rapid deployment across 100+ countries.

Construction: Certified Installation

Field teams install single-axis trackers with military-grade precision, achieving ≤4Ω grounding resistance. Our 48GW track record includes Japan's largest floating solar farm.

Why Global Leaders Choose EPC Providers

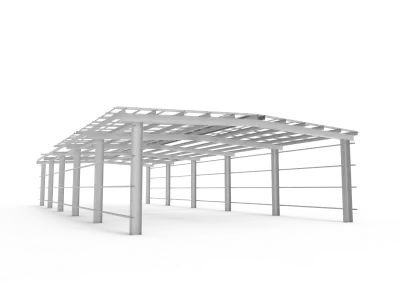

30% Faster Deployment

Integrated teams eliminate contractor coordination delays. Our carport systems install in 60% less time than industry averages.

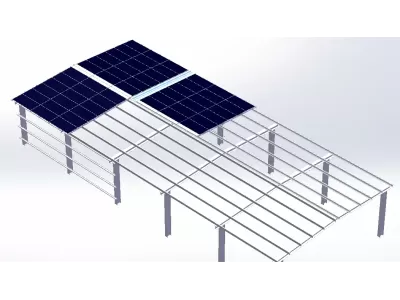

15% Lower LCOE

Bulk procurement of roof mounts reduces hardware costs, while optimized designs increase energy yield 25% for dual-axis projects.

Risk Mitigation

Single-contractor responsibility covers everything from typhoon-resistant structural calculations to O&M handover documentation.

Global Top 3 Solar EPC Innovators

As confirmed by the 2024 Global Solar Mounting Report, Grace Solar ranks #3 worldwide in EPC-integrated solutions, leading Japan's market with 34% share. Our AI-powered GS-Light trackers demonstrate why Fortune 500 partners choose us for bankable 25-year performance.

Technology Differentiation

Our 2000m² R&D center develops proprietary solutions like:

- Real-time wind-load adjustment algorithms

- Self-powered tracker systems with ≤0.5° deviation

- BIPV-specific corrosion resistance coatings

Your EPC Project Execution Roadmap

Phase 1: Digital Twin Simulation

3D modeling for solar farms optimizes row spacing ±2cm accuracy

Phase 2: Automated Manufacturing

Robotic production of 15GW/year tracker components

Phase 3: Drone-Assisted QA

Thermal imaging verifies 10,000+ daily connections

Ready to partner with a Top 3 EPC specialist?

Explore Grace Solar's EPC Solutions