Table of Contents

What is a Solar Mounting System?

Often called solar racking or photovoltaic mounting systems, a solar mounting system is the critical framework that securely anchors solar panels to your roof, the ground, or other structures. While solar panels capture the spotlight, the mounting system serves as the indispensable foundation—the unsung hero that ensures the entire photovoltaic (PV) installation remains secure, optimized, and productive for 25 years or more.

Think of it as the chassis of a car and the foundation of a building combined. It must provide unwavering structural support while positioning the panels at precise angles to maximize solar exposure. A high-quality system, like those engineered by Grace Solar, is designed to be durable, corrosion-resistant, and engineered to withstand extreme environmental challenges—from 120 mph winds to heavy snow loads—ensuring your energy investment remains protected and profitable for decades.

Beyond simple attachment, advanced mounting systems contribute significantly to the overall system performance. Proper orientation and tilt angle can increase energy production by 10-25% compared to poorly angled installations. The mounting system also manages critical airflow beneath panels, reducing operating temperatures and preventing efficiency losses during peak sunlight hours.

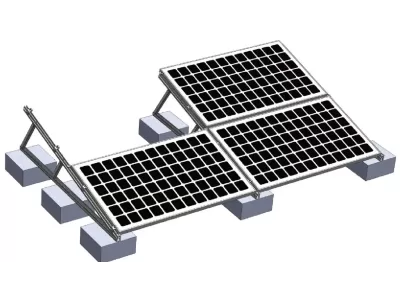

Key Components of a Solar Racking System

Understanding the anatomy of a solar mounting system helps appreciate the engineering behind a secure installation. While designs vary by application and manufacturer, most systems incorporate these fundamental components:

1. Mounting Rails

These longitudinal aluminum or steel extrusions form the primary structural framework. They run parallel to solar panels, providing the attachment points for all other components. High-quality rails feature precisely engineered profiles for optimal strength-to-weight ratios and integrated cable management channels for clean wire organization. The material selection—typically anodized aluminum or galvanized steel—determines both corrosion resistance and structural capacity.

2. Clamps

These precision components create the physical connection between solar panels and mounting rails. Mid-clamps secure adjacent panels by connecting their frames to a shared rail, while end-clamps anchor the outermost panels. Modern clamp designs incorporate specialized polymers to prevent galvanic corrosion between dissimilar metals while maintaining sufficient torque retention under thermal cycling conditions.

3. Roof Attachments & Flashings

For rooftop installations, attachments (commonly called "feet" or "L-feet") transfer all structural loads to the building's framework. The critical companion to these attachments is flashing—a waterproofing membrane or metal shield that creates a weatherproof seal around penetration points. Advanced flashing systems, like those used in Grace Solar's roof mounts, often incorporate multiple barrier layers and compression gaskets to guarantee absolute water integrity for the lifetime of the installation.

4. Ground Screws or Foundations

For ground mount systems, these elements replace roof attachments. Ground screws—helical piles twisted into the earth—offer rapid installation and immediate load-bearing capacity without concrete curing time. Alternative foundation methods include driven piles, concrete caissons, or ballasted systems using weighted bases for sites where ground penetration is restricted.

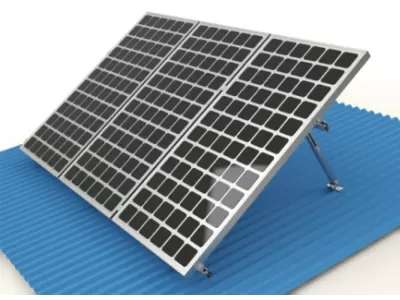

5. Tilt Legs and Adjustment Systems

Particularly crucial for flat roof and ground mount applications, these components enable precise angular adjustment of the mounting rails. Engineers optimize these tilt angles based on geographic latitude, seasonal sun path variations, and specific energy production goals. Sophisticated systems offer field-adjustable angles to accommodate changing requirements or to optimize for seasonal production peaks.

Types of Solar Mounting Systems

The solar industry has developed specialized mounting solutions for virtually every conceivable application. Selecting the appropriate system requires careful evaluation of site conditions, energy requirements, and budget constraints.

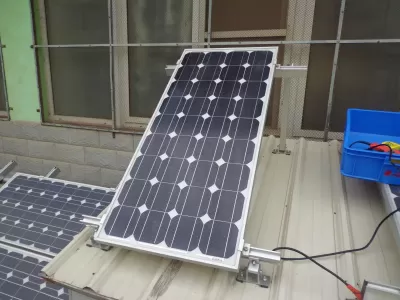

1. Roof Mounting Systems

As the predominant choice for residential and commercial buildings, roof mounts maximize unused space while minimizing land footprint. These systems require meticulous engineering to accommodate specific roofing materials and structural capacities.

- Pitched Roof Systems: Engineered for sloped roofs (asphalt shingle, clay tile, metal seam). They include rail-based systems (universal compatibility), rail-less systems (lower profile, faster installation), and shared-rail configurations (reduced material cost).

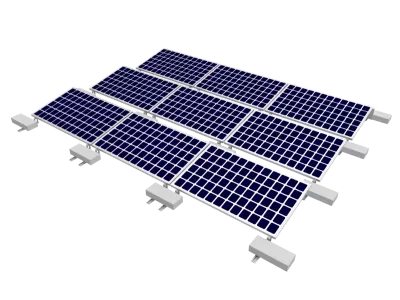

- Flat Roof Systems: These solutions typically employ ballasted racks (weight-secured without roof penetration) or mechanically attached triangular elevated frames that create optimal tilt angles while preserving roof membrane integrity. Ballast calculations must account for local wind uplift forces and roof load capacity.

Explore our versatile solar roof mounting solutions designed for all roof profiles and certified for the most demanding wind and snow regions.

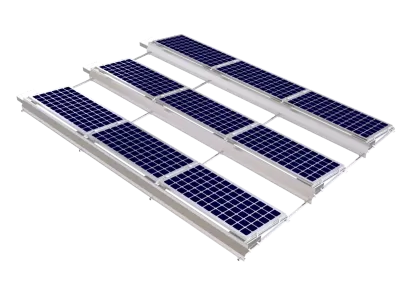

2. Ground Mounting Systems

When roof space proves insufficient, shaded, or structurally inadequate, ground mounts offer superior flexibility for panel orientation and maintenance access.

- Fixed-Tilt Ground Mounts: The most common and economical approach, with panels fixed at an angle optimized for annual production. These systems offer exceptional reliability with minimal maintenance requirements.

- Ballasted Ground Mounts: Utilizing concrete weights instead of deep foundations, these non-penetrating systems preserve ground integrity and are ideal for environmentally sensitive areas, capped landfills, or temporary installations.

- Pile-Driven Systems: Using vibration-free hydraulic drivers to install steel posts rapidly, these systems combine the stability of deep foundations with minimal site disturbance and no concrete curing delays.

3. Solar Tracking Systems

For maximum energy generation, solar tracking systems represent the pinnacle of mounting technology. These active systems dynamically follow the sun's diurnal path, dramatically increasing energy harvest.

- Single-Axis Trackers: Rotate panels along a north-south axis, following the sun from east to west. These systems typically boost annual energy production by 25-30% compared to fixed-tilt systems, delivering the lowest levelized cost of energy (LCOE) for utility-scale projects.

- Dual-Axis Trackers: Provide complete solar orientation by tracking both daily movement and seasonal altitude variations. While achieving the highest possible energy gain (over 35%), their increased complexity makes them most suitable for specialized applications where maximum power density is critical.

Modern trackers incorporate sophisticated control algorithms that weigh energy capture benefits against motor activation costs, with some systems now offering backtracking features to prevent inter-row shading during sunrise and sunset.

4. Specialized Mounting Systems

The application of solar technology continues to expand into novel environments, driving innovation in mounting solutions:

- Carport Mounts: Transform underutilized parking areas into shaded, power-generating assets while providing weather protection for vehicles and EV charging infrastructure.

- Floating Mounts: Install solar arrays on reservoirs, ponds, and lakes, conserving valuable land, reducing water evaporation, and benefiting from natural cooling effects that boost panel efficiency.

- BIPV (Building-Integrated Photovoltaics): These systems replace conventional building materials with solar-generating equivalents, creating seamless architectural integration while serving dual purposes as weather envelope and power generator.

- Agricultural PV: Elevated structures that enable dual land use for both crop production and energy generation, with panel height and spacing optimized for specific agricultural requirements.

How to Choose the Right Solar Mounting System

Selecting the optimal racking system requires balancing technical requirements, economic factors, and site-specific constraints. This decision significantly impacts both installation costs and long-term energy yield.

- Site Assessment: Comprehensive evaluation of available space—roof condition, material, and orientation for rooftop systems; soil composition, topography, and shading for ground mounts. Professional structural analysis is essential for rooftop installations.

- Local Climate & Environmental Loads: The system must be certified for local wind speeds (including hurricane regions), snow accumulation, seismic activity, and corrosion potential (particularly coastal salt spray environments).

- Energy Production Goals: Fixed-tilt systems offer predictability and reliability, while tracking systems maximize production per square meter. The choice depends on energy requirements, available space constraints, and financial optimization.

- Regulatory Compliance: Compliance with building codes, fire department setback requirements, electrical codes, and utility interconnection standards is non-negotiable. Systems should carry relevant certifications (UL, TÜV, IEC) for your market.

- Lifecycle Cost Analysis: Consider both initial investment and long-term operational costs. While premium systems may have higher upfront costs, their durability, maintenance requirements, and production advantages often deliver superior lifetime value.

- Installation Logistics: Evaluate installation complexity, specialized equipment requirements, and labor hours. Streamlined systems with pre-assembled components can significantly reduce installation time and cost.

- Future Expansion & Maintenance: Design with future system expansion in mind. Ensure adequate access for panel cleaning, inspection, and potential component replacement over the system's 25+ year lifespan.

For all installations, having the right solar mounting components and accessories is essential for a secure, compliant, and optimized solar installation.

Why Partner with Grace Solar for Your Mounting Solutions?

With over a decade of dedicated innovation and a global cumulative installed capacity exceeding 48GW, Grace Solar has established itself as a world-leading, trustworthy brand for intelligent solar mounting solutions. Our mission—"mount every solar plant firm as rock, bring more profits from the sun"—drives our engineering philosophy and quality standards across every product line.

We offer a comprehensive portfolio of integrated solar solutions, from our advanced GS-Light intelligent tracking system and robust GS-Smart ground mounts to our reliable GS-Energy roof mounting systems. Our product development integrates cutting-edge technologies including AI-powered optimization, IoT connectivity for remote monitoring, and compatibility with emerging energy storage architectures.

What distinguishes Grace Solar in the global marketplace:

- Proven Performance: Ranked among the top 5 globally in market share and #1 in the demanding Japanese market, with successful projects across 100+ countries

- Engineering Excellence: Over 100 patents and a fully-equipped R&D laboratory continuously advancing mounting technology

- Rigorous Certification: Comprehensive certification portfolio including UL, TUV, CE, JIS, MCS, and region-specific wind tunnel testing

- Manufacturing Scale: 110,000m² production facility with 15GW annual capacity ensures reliable supply and competitive pricing

- Bankability: Independent bankability reports provide financial institutions confidence in project investments using our systems

By choosing Grace Solar, you're not merely purchasing mounting hardware—you're investing in engineering excellence, unparalleled durability, and a strategic partnership dedicated to maximizing the return on your solar investment throughout its entire operational lifecycle. Our global team stands ready to support your projects with technical expertise, custom engineering solutions, and the reliability that comes from a company with a "do it right the first time" core value.

/Adjustable%20solar%20ground%20mount%20system%20on%20snowy%20mountain%20with%2055%20Angle%20tilt_-400x300w.webp)

/Engineer%20assembling%20Grace%20Solar's%20portrait%20ground%20mount%20in%20typhoon%20area_-400x300w.webp)