Table of Contents

1. What Exactly is a Solar Mounting Bracket?

A solar mounting bracket—often called solar racking or a mounting system—is the engineered backbone of any photovoltaic (PV) installation. It is the critical framework that securely anchors solar panels to rooftops, the ground, or other structures, ensuring they remain stable, optimally angled, and productive for 25 years or more.

While solar panels capture the spotlight, the mounting system performs the essential, unsung work: withstanding extreme weather (from typhoons to heavy snow), maximizing energy yield through precise positioning, and protecting your roof and investment. Industry analysis suggests the racking system constitutes about 10% of the total system cost but is responsible for 100% of its physical integrity and safety. A failure here can compromise the entire energy generation asset.

The evolution of mounting technology has been significant. From early, heavy custom-welded frames, the industry has moved toward lightweight, adjustable, and pre-engineered systems designed for rapid installation and universal compatibility. Modern systems must balance strength with ease of handling, and durability with cost-effectiveness.

At Grace Solar, with over a decade of innovation and a presence in more than 100 countries, we define a premium mounting bracket by its unwavering adherence to one core principle: “Mount every solar plant firm as rock.” It’s not just hardware; it’s the foundation of trust in solar energy, engineered to deliver a fast payback and stable growth over its lifetime.

2. Main Types of Solar Mounting Systems

Selecting the correct type is the first major decision in your solar journey. The right choice balances site specifics, energy goals, and budget. There is no universal "best" system, only the best system for your specific project conditions.

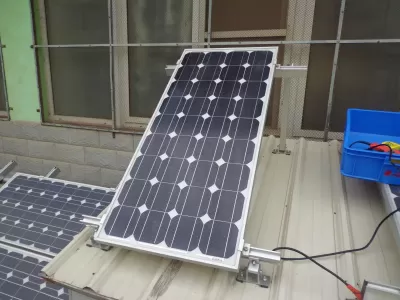

2.1 Roof Mounting Systems

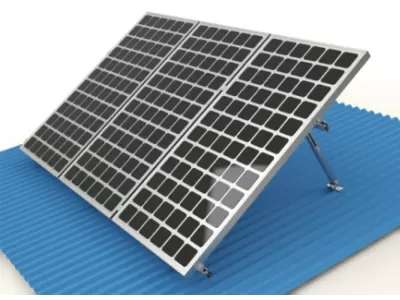

The most common choice for residential and commercial buildings. A quality roof system must adapt to various materials (asphalt, tile, metal) without compromising waterproof integrity. Key design philosophies include rail-based systems (the traditional standard) and modern direct-attach or rail-less systems, which reduce parts count and weight.

- Pitched Roof Systems: Utilize rails and adjustable brackets to secure panels flush or at a tilt. Solutions like our GS-Energy system are engineered for speed, security, and compatibility with all major roof types, ensuring a watertight seal is maintained.

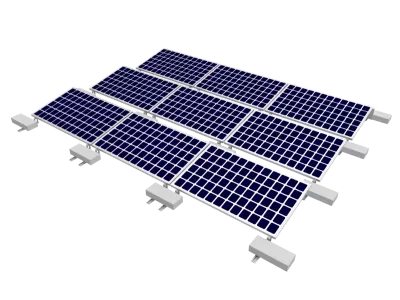

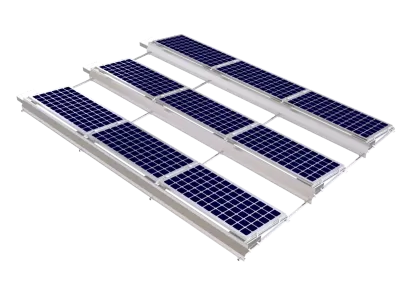

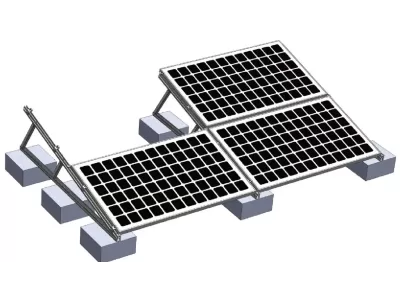

- Flat Roof Systems: Often use ballasted designs (non-penetrating) or low-profile tilt frames to optimize angle without roof damage. These systems must account for wind uplift forces carefully, often requiring engineering approval.

2.2 Ground Mounting Systems

Ideal when roof space is unsuitable, shaded, or poorly oriented. They offer superior flexibility for achieving the perfect tilt and azimuth angles, which can significantly boost annual energy production compared to a constrained roof installation.

- Fixed-Tilt Ground Mounts: The cost-effective, rugged workhorse for large-scale installations. Our GS-Smart system, built with high-strength Q235/Q355 steel, delivers unmatched stability for utility-scale projects and is designed for quick assembly to reduce labor costs.

- Solar Trackers: Advanced systems that follow the sun, boosting energy yield by 25-35%. Our GS-Light AI Tracking System represents the cutting edge, using intelligent algorithms and reliable drives to maximize ROI, making it a compelling choice for high-value, large-area solar farms.

2.3 Specialized Mounting Solutions

The solar landscape is evolving, demanding innovative mounting solutions that go beyond traditional rooftops and fields. Grace Solar is pioneering in these niche but growing markets, offering integrated Solar Solutions.

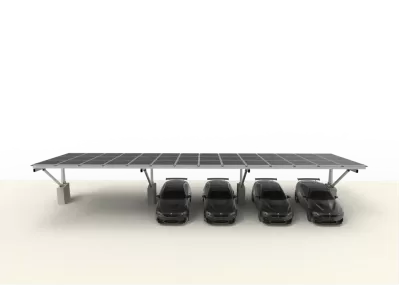

- Carport & Pergola Systems: Dual-purpose structures that generate power while providing shade for vehicles or outdoor spaces, adding value to commercial and residential properties.

- Floating PV Mounts: Designed for reservoirs and lakes, requiring exceptional corrosion resistance and a design that considers wave action and water level changes.

- Energy Storage Integrated Mounts: A critical innovation as solar-plus-storage becomes standard. We provide custom-designed brackets for solar installations on energy storage containers. These systems are engineered to reduce interior temperature by providing shade and enhancing airflow, thereby extending battery life and improving system safety—a direct application of our mission to integrate new technologies.

3. Material Showdown: Aluminum vs. Steel

The material choice is a fundamental engineering decision that dictates the system's lifespan, strength, weight, and ultimately, its suitability for your project. It's a trade-off between cost, performance, and environmental conditions.

| Material | Key Properties & Advantages | Limitations | Ideal Application |

|---|---|---|---|

| Aluminum Alloy | Lightweight (2.71 g/cm³), excellent natural corrosion resistance, low maintenance, no need for painting, easy to handle and install. | Higher cost per unit strength, lower load capacity than steel, can be prone to galvanic corrosion if coupled improperly with other metals. | Residential rooftops (where weight is a concern), coastal environments, decorative structures like solar pergolas. |

| Galvanized Steel (Q235/Q355) | Superior strength-to-cost ratio, extremely robust for heavy loads and long spans. When coated with advanced alloys like ZM275 (Zinc-Aluminum-Magnesium), it offers decades of rust protection even in harsh environments. | Heavier (7.85 g/cm³), requires high-quality coating to prevent corrosion; cutting or drilling can expose raw steel edges that need touch-up protection. | Large-scale ground-mounted power plants, high wind/snow load regions, cost-sensitive commercial projects, and heavy-duty applications like our G58 energy storage bracket systems. |

At Grace Solar, our fully-equipped laboratory validates every material batch against rigorous standards. Our products carry major international certifications (UL, TUV, CE, JIS, MCS), ensuring they meet the “Do it right the first time” standard. Whether it’s lightweight aluminum for a sleek rooftop or ultra-strong, hot-dip galvanized steel for a mountainous utility site, our material selection is driven by project-specific engineering, not a one-size-fits-all approach.

4. Key Components of a Solar Racking System

Understanding the anatomy of a racking system ensures you appreciate its engineering and can communicate effectively with installers or suppliers. A typical system is a modular kit comprising:

- Mounting Brackets/Feet: The primary anchor point to the roof truss, concrete foundation, or ground post. These are often L-shaped or U-shaped and are the first line of defense against pull-out forces.

- Rails (or Rails for Rail-less Systems): The longitudinal beams that form the primary support structure. They must be straight and strong to minimize deflection under load. Modern rails often feature integrated cable management channels.

- Module Clamps: Specialized hardware that secures panels to the rails without drilling into the panel frame (which would void warranties). They come as mid-clamps (between panels) and end-clamps (at the ends of rows).

- Flashings & Sealants: Critical for penetrated roof systems. A flashing is a metal or plastic piece that integrates with the roof covering to create a watertight seal around the bracket's bolt. Quality here is non-negotiable to prevent leaks.

- Hardware (Bolts, Nuts, Washers): Often overlooked but vital. Must be made of compatible materials (e.g., stainless steel with aluminum) to prevent galvanic corrosion and be torqued to precise specifications.

5. Critical Installation Considerations

Even the best bracket system can fail if installed incorrectly. Key considerations that go beyond the hardware itself include:

- Structural Analysis: The roof or ground must be able to support the additional dead load (weight) and wind/snow live loads. A professional structural assessment is often required, especially for older buildings or large arrays.

- Wind & Snow Load Calculations: These are codified based on location. Systems must be rated for local conditions. Grace Solar provides site-specific Wind Tunnel Test Reports and engineering certifications to satisfy permit requirements.

- Thermal Expansion & Contraction: Metal expands when hot and contracts when cold. Racking designs must allow for this movement to prevent stress buildup that could warp rails or loosen connections.

- Electrical Grounding: The entire metal racking system must be properly bonded and grounded to protect against lightning strikes and fault currents, a critical safety requirement often detailed in the installation manual.

6. How to Choose the Right Solar Mounting Bracket

Follow this expert checklist to make an informed decision that ensures safety, performance, and value for money over the system's lifetime:

- Conduct a Thorough Site Assessment: Evaluate roof type/material, ground soil conditions, shading, and local climate/wind/snow load codes. This data is the foundation of all subsequent choices.

- Define Your Primary Project Goal: Is it maximum energy yield (favoring trackers or optimized tilt), lowest upfront cost (favoring simple fixed-tilt), aesthetic integration, or fastest installation time?

- Verify Compliance and Certification: Ensure the system meets all local building codes, utility requirements, and has relevant certifications. Our globally certified (UL, TUV, etc.) products are designed to streamline this approval process worldwide.

- Evaluate Total Cost of Ownership (TCO): Look beyond the initial price per kW. Consider durability, maintenance needs, warranty length, and how the design affects installation labor costs. A slightly more expensive, pre-assembled system can save thousands in labor.

- Choose an Engineering Partner, Not Just a Supplier: Look for proven experience, financial stability, and responsive technical support. With a 48GW+ global installation footprint, a 10-year product warranty, and a position among the top global manufacturers, Grace Solar offers more than products. We deliver certainty, from initial system design and engineering support to reliable delivery and after-sales service, embodying our core value of being the “Most trustworthy products and service.”

Build Your Solar Project on a Foundation of Rock-Solid Engineering

Your mounting system is a 25-year commitment that underpins your entire solar investment. Don't compromise on its quality. Choose the engineering excellence, proven global experience, and unwavering reliability that Grace Solar provides. Explore our complete range of smart solar mounting solutions and let our team of experts help you build a system that stands firm against time and the elements, delivering maximum profits from the sun.

View Our Solar Solutions Contact for a Custom Quote

/Al-Zn-Mg%20coated%20piling%20structure%20for%20extreme%20weather%20resistance_-400x300w.webp)

/Double-column%20carbon%20steel%20solar%20ground%20mount%20system%20with%20portrait%20panel%20arrang_-400x300w.webp)

/Aluminum%20alloy%20solar%20ground%20mounting%20system%20on%20sloped%20terrain_-400x300w.webp)

/Single-column%20piling%20foundation%20for%20landscape-friendly%20solar%20installation_-400x300w.webp)