Table of Contents

- What is a Solar Energy Plant?

- Photovoltaic (PV) Power Plant Technology

- Concentrated Solar Power (CSP) Plant Technology

- Global Market Trends & Largest Solar Plants

- Smart Mounting Solutions for Solar Plants

- Optimizing Your Solar Plant Project

What is a Solar Energy Plant?

A solar energy plant, also known as a solar farm, photovoltaic (PV) power station, or utility-scale solar project, is a large-scale installation designed to convert sunlight into electricity for supply to the power grid. Unlike residential rooftop systems, these plants generate power at the utility level, often with capacities ranging from several megawatts (MW) to multiple gigawatts (GW).

There are two primary technological pathways for utility-scale solar generation, both of which rely on precision-engineered support structures to achieve optimal performance and return on investment (ROI):

- Photovoltaic (PV) Power Plants: The most widespread technology, using arrays of semiconductor solar panels to directly convert sunlight into direct current (DC) electricity, which is then inverted to alternating current (AC) for the grid.

- Concentrated Solar Power (CSP) Plants: Utilize mirrors (heliostats or parabolic troughs) to concentrate sunlight onto a receiver, generating high-temperature heat. This heat is then used to drive a conventional steam turbine, generating electricity. A key advantage is the ability to integrate thermal energy storage for dispatchable power.

According to the U.S. Energy Information Administration (EIA), solar power plants do not produce air pollution or greenhouse gases during operation, making them a clean alternative to fossil fuel-based generation. The design and engineering of these facilities have evolved significantly since the first 1 MW plant was built in California in 1982.

Photovoltaic (PV) Power Plant Technology

Modern PV plants are engineering marvels composed of several critical subsystems. The efficiency and financial success of the project hinge not just on the solar modules, but equally on the structural foundation that holds them. The technology has advanced from simple fixed installations to sophisticated systems incorporating tracking and smart management.

Core Components of a PV Plant

- Solar Array: The heart of the plant, comprising thousands of PV modules electrically connected into strings. The energy yield is directly influenced by the stability, orientation, and tilt angle of the supporting structure. Modern plants use panels with efficiencies exceeding 20%, arranged to maximize land use.

- Mounting & Tracking Systems: This is the critical backbone. Fixed-tilt systems are a robust and cost-effective solution for many locations, typically angled to optimize annual yield. For maximum energy harvest, single-axis and dual-axis solar trackers actively follow the sun's path. Advanced trackers can increase annual energy yield by 25-30% compared to fixed structures, dramatically improving project economics.

- Power Conversion & Grid Connection: Inverters convert the DC electricity from the arrays into grid-compatible AC. Centralized inverters handle large blocks of arrays, while string inverters offer more granular control and higher efficiency in uneven terrain. Transformers then step up the voltage for efficient long-distance transmission.

The performance ratio (PR) of a modern solar plant—measuring the actual AC output against the theoretical DC capacity—typically exceeds 80%, thanks to improved component quality and sophisticated system design. Companies with extensive global experience, like Grace Solar, contribute to these high standards through engineered solutions that minimize losses.

Concentrated Solar Power (CSP) Plant Technology

CSP plants offer a unique value proposition: the ability to store thermal energy and generate electricity on demand, even after sunset. This makes them a valuable asset for grid stability in high-renewable penetration scenarios, addressing the "duck curve" challenge faced by grids with high PV penetration.

Types of CSP Systems

- Parabolic Troughs: Long, curved mirrors focus sunlight onto a receiver tube running along their focal line, heating a thermal transfer fluid (often synthetic oil or molten salt) to temperatures around 400°C.

- Solar Power Towers: A field of flat mirrors (heliostats) focuses sunlight onto a central receiver atop a tower, achieving very high temperatures (exceeding 560°C), which improves thermodynamic efficiency.

- Linear Fresnel Reflectors: Use nearly flat, segmented mirrors to focus light onto a fixed linear receiver, offering a lower-cost alternative to parabolic troughs.

- Thermal Energy Storage (TES): A game-changer for CSP. Excess heat is stored in molten salt tanks during the day and used to generate steam at night, providing up to 12-15 hours of dispatchable power, as seen in plants like Solana in Arizona.

Key Engineering Challenge: CSP requires extremely precise and robust mounting for its mirrors to maintain perfect optical focus under all environmental conditions, including high winds. The engineering precision required for these large-scale, dynamic structures is a core competency for specialized providers who serve both the PV and CSP markets. For instance, engineered solar solutions must account for millimeter-level accuracy in mirror alignment over thousands of hectares.

Global Market Trends & Largest Solar Plants

The solar industry is experiencing unprecedented growth. According to the International Energy Agency (IEA), solar PV is on track to become the largest source of global electricity capacity by 2029, accounting for 80% of new renewable capacity additions between 2024 and 2030. The International Renewable Energy Agency (IRENA) reported that global solar PV capacity reached nearly 1.9 Terawatts by the end of 2024, with utility-scale plants making up a significant portion.

This boom is fueled by rapidly declining Levelized Cost of Electricity (LCOE)—which fell by over 90% in the last decade—and the commissioning of mega-projects that push engineering boundaries:

- Xinjiang Solar Farm, China: Currently the world's largest at approximately 5 GW, showcasing the scale of modern solar development.

- Bhadla Solar Park, India: A colossal ~2.7 GW facility spread over 14,000 acres in the Rajasthan desert.

- Benban Solar Park, Egypt: A ~1.5 GW landmark comprising 32 co-located projects, demonstrating successful multi-developer cluster development.

- Mohammed bin Rashid Al Maktoum Solar Park, UAE: A multi-technology hub aiming for 5 GW by 2030, combining PV and CSP with extensive storage.

Supporting this global expansion requires reliable partners with a proven track record. Experience gained from hundreds of projects across diverse climates is invaluable. For example, providers with a cumulative installed capacity of 48GW across more than 100 countries have tested and proven their mounting solutions in the most challenging environments, from the deserts of the Middle East to the high-wind coasts of Australia and Japan.

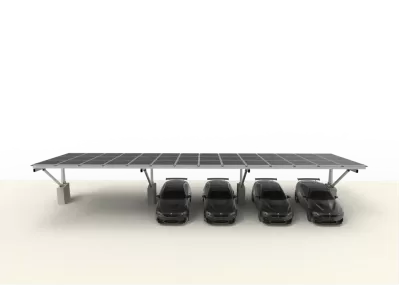

Smart Mounting Solutions for Solar Plants

Choosing the right mounting system is one of the most consequential decisions for a solar plant's lifetime performance. It is not just "hardware"; it is the engineered foundation that determines structural integrity, land use efficiency, operational resilience, and ultimately, financial returns. A poorly designed mounting system can lead to increased O&M costs, underperformance, and even structural failure.

The Evolution from Structure to Smart System

Modern mounting solutions have evolved into integrated smart systems. The best solutions now incorporate:

- AI-Powered Tracking: Algorithms that use weather forecasts, real-time irradiance data, and historical performance to optimize the tilt angle, not just for maximum sun exposure but also to mitigate soiling and wind loads.

- IoT Connectivity: Sensors monitor torque, vibration, and alignment, enabling predictive maintenance and early detection of issues before they cause downtime.

- Digital Twin Integration: Creating a virtual model of the physical plant to simulate performance under different scenarios and optimize operations.

- Agrivoltaics & Dual-Use Design: Engineered structures that allow for the co-development of solar and agriculture, maximizing land value and community acceptance.

Comprehensive Product Ecosystem for Success

Leading providers offer a comprehensive suite of smart solar solutions designed to meet every project need:

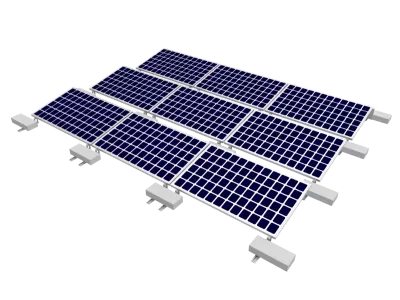

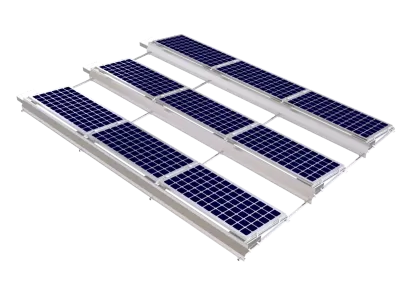

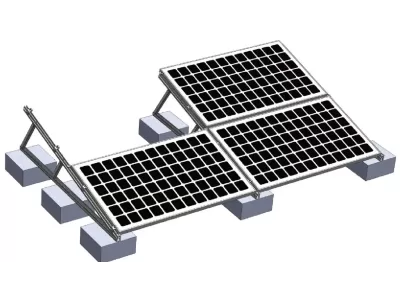

- High-Performance Ground Mount Systems: Engineered for rapid installation, unparalleled durability (often with a 25+ year design life), and optimal load distribution to withstand extreme weather events. These systems are the workhorse for most utility-scale fixed-tilt installations.

- Intelligent Single-Axis Trackers: The industry standard for maximizing yield. The latest models feature advanced backtracking algorithms to eliminate inter-row shading and sophisticated wind stow strategies that protect assets during storms without sacrificing precious production time.

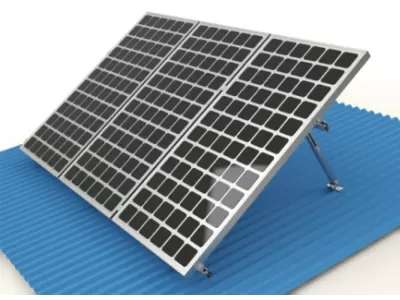

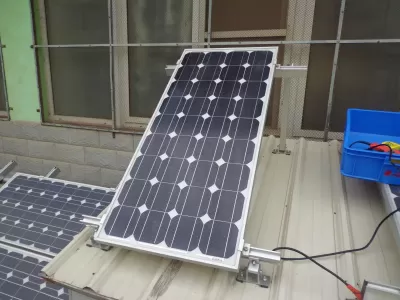

- Robust Roof Mounting Systems: For commercial and industrial (C&I) distributed generation, providing secure, non-penetrating solutions for various roof types (metal, membrane, concrete) that preserve roof warranties.

- Custom Energy Storage & CSP Mounting: Tailored, safe, and compliant racking solutions for battery energy storage systems (BESS) and the precise mirror supports required for CSP plants. Contacting a specialist is crucial for these complex, project-specific requirements.

Optimizing Your Solar Plant Project

The success of a utility-scale solar project depends on meticulous planning and choosing partners who add value beyond the component. The mounting system is a long-term investment that impacts every aspect of the plant's life cycle, from initial geotechnical studies and yield modeling through to decommissioning.

Key Considerations for Project Developers and EPCs:

- Site-Specific Engineering: Soil conditions, wind/snow loads, seismic activity, and topography dictate the mounting system design. Generic solutions can lead to over-engineering (increasing cost) or under-engineering (increasing risk).

- Total Lifetime Cost: Evaluate the CapEx against the expected OpEx and energy yield gain. A slightly higher initial investment in a superior tracking system can pay back multiples over the plant's life through increased production and reduced maintenance.

- Supply Chain & Logistics: Ensure your supplier has the global manufacturing footprint and logistical expertise to deliver on schedule, avoiding costly construction delays.

- Certifications & Bankability: Insist on products with independent certifications (UL, TUV, etc.) and a track record supported by bankability reports from leading technical advisors. This is non-negotiable for securing project financing.

When evaluating partners, consider their global experience, in-house engineering capability, commitment to R&D and innovation, and proven ability to deliver on the promise of maximum energy yield and reliability. The right partner acts as an extension of your engineering team, ensuring your project is built on a foundation of excellence to achieve the fastest payback and most stable long-term growth.

Ready to build a solar plant on a foundation of smart engineering and proven performance? A conversation with an experienced solution provider can help you navigate these critical choices. Contact us today for a detailed consultation and project assessment tailored to your specific site and goals.

/Al-Zn-Mg%20coated%20piling%20structure%20for%20extreme%20weather%20resistance_-400x300w.webp)

/Double-column%20carbon%20steel%20solar%20ground%20mount%20system%20with%20portrait%20panel%20arrang_-400x300w.webp)

/Aluminum%20alloy%20solar%20ground%20mounting%20system%20on%20sloped%20terrain_-400x300w.webp)

/Single-column%20piling%20foundation%20for%20landscape-friendly%20solar%20installation_-400x300w.webp)