Table of Contents

Understanding Solar Panel Mounting Aluminum Rails

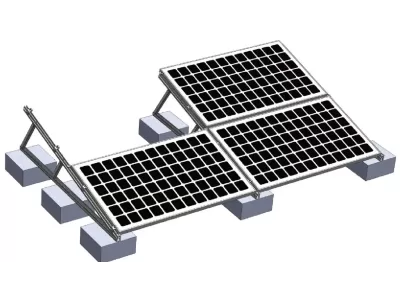

Solar panel mounting aluminum rails form the fundamental backbone of any professional photovoltaic installation system. These structural components serve as the primary framework that securely holds solar panels in position on various roof types while withstanding environmental challenges for decades of reliable performance.

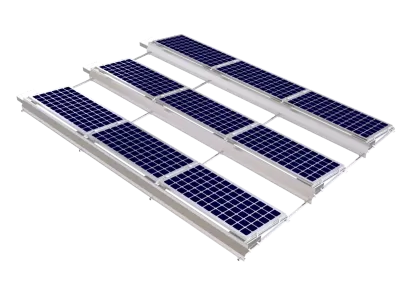

The aluminum rail system typically consists of longitudinal rails running parallel to the roof surface, which are then attached to roof-mounted brackets or feet. Solar panels are subsequently clamped to these rails, creating a stable and durable array capable of lasting 25-30 years or more. The precision engineering of these rails ensures proper weight distribution and structural integrity across the entire solar array.

Primary Functions of Mounting Rails

Aluminum rails perform several critical functions in solar installations. They provide structural support for solar panels, distribute weight evenly across the roof surface, allow for precise panel positioning and alignment, accommodate thermal expansion and contraction, and facilitate proper water drainage and ventilation beneath panels. Additionally, they enable easy maintenance access and potential future system expansions.

Key Specifications and Technical Requirements

When selecting aluminum rails for solar mounting systems, several technical specifications demand careful consideration to ensure optimal performance and longevity. Understanding these specifications helps installers and project developers make informed decisions based on local conditions and project requirements.

Material Composition and Standards

High-quality solar mounting rails are typically manufactured from 6005-T5 or 6063-T6 aluminum alloys, which offer excellent strength-to-weight ratios and superior corrosion resistance. These materials comply with international standards including ASTM B221 and EN 755-2, ensuring consistent quality and performance. The anodizing process further enhances durability, with typical coating thicknesses of 15-25 microns providing additional protection against environmental elements.

Structural Load Capacity

Professional-grade aluminum rails must withstand significant structural loads, including wind loads up to 150 mph (240 km/h), snow loads exceeding 40 psf (1.9 kPa), seismic loads per local building codes, and dynamic loads during installation and maintenance. Advanced rail systems feature reinforced designs with moment of inertia values typically ranging from 10-25 cm⁴, ensuring they can handle these demanding conditions while maintaining panel alignment and system integrity.

Benefits and Advantages of Aluminum Rails

Aluminum rails offer numerous advantages that make them the preferred choice for solar installations worldwide. Their unique combination of properties makes them ideal for both residential and commercial solar applications across diverse climatic conditions.

Corrosion Resistance and Durability

Aluminum naturally forms a protective oxide layer when exposed to atmosphere, providing exceptional resistance to corrosion. This characteristic is further enhanced through anodizing processes, making aluminum rails ideal for coastal environments and industrial areas with high pollution levels. Unlike steel, aluminum doesn't require painting or extensive maintenance, reducing long-term ownership costs and ensuring consistent performance throughout the system's lifespan.

Lightweight Yet Strong

With a density approximately one-third that of steel, aluminum significantly reduces the dead load on roof structures while maintaining impressive strength characteristics. This weight advantage translates to easier handling during installation, reduced structural requirements, and lower shipping costs. Modern aluminum rail profiles achieve strength comparable to steel while weighing only 1.5-2.5 kg per meter, making them ideal for both new construction and retrofit applications.

Thermal Performance and Expansion

Aluminum's thermal expansion coefficient closely matches that of solar panel frames, minimizing stress at connection points during temperature fluctuations. This compatibility ensures long-term reliability and reduces the risk of micro-cracks in solar cells. Aluminum's excellent thermal conductivity also helps dissipate heat from panels, potentially improving energy production efficiency by reducing temperature-related performance losses.

Installation Best Practices and Techniques

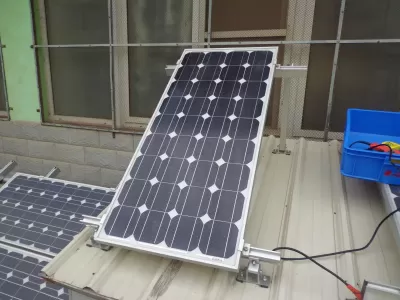

Proper installation techniques are crucial for maximizing the performance and lifespan of aluminum rail mounting systems. Following industry best practices ensures system reliability, safety, and optimal energy production throughout the installation's operational life.

Rail Layout and Spacing

Optimal rail spacing depends on panel dimensions, expected loads, and rail profile strength. Generally, rails should be positioned to support panels at the manufacturer-specified mounting points, typically 24-48 inches (600-1200 mm) apart depending on panel size and local wind/snow conditions. For larger panels or high-wind areas, closer spacing or heavier rail profiles may be necessary to prevent deflection and ensure long-term structural integrity.

Fastening and Connection Systems

Professional installation requires stainless steel fasteners (typically 304 or 316 grade) to prevent galvanic corrosion. Proper torque specifications must be followed for all connections, and anti-seize compound should be used in corrosive environments to maintain disassembly capability. Modern rail systems feature T-slot designs that allow for adjustable positioning and secure clamping, with end caps and splices ensuring complete system integration and weather protection.

Grace Solar Aluminum Rail Solutions

With over a decade of industry leadership, Grace Solar has established itself as a trusted global provider of high-performance aluminum rail systems. Our extensive experience spans more than 100 countries with a cumulative installed capacity of 48GW worldwide, demonstrating our commitment to quality and reliability in every project we undertake.

Engineering Excellence and Innovation

Grace Solar's aluminum rails incorporate advanced engineering features including optimized extrusion profiles for maximum strength-to-weight ratio, precision T-slots for universal compatibility, and specialized anodizing treatments for enhanced corrosion protection. Our rails are designed to integrate seamlessly with our comprehensive universal mounting solutions. The innovative design includes pre-marked measurement indicators for faster installation and integrated grounding features for enhanced safety compliance.

Quality Assurance and Certifications

All Grace Solar aluminum rails undergo rigorous testing and quality control procedures. Our products hold prestigious international certifications including UL 2703, TUV, CE, JIS, and MCS, ensuring compliance with the highest global standards for safety and performance. Our 2000m² experiment center conducts continuous research and development, while our ISO 9001 certified manufacturing processes guarantee consistent quality across our entire product range.

Global Project Experience

Our aluminum rail systems have been deployed in diverse climatic conditions from the harsh environments of the Middle East to the heavy snow loads of Northern Europe and the high-wind regions of coastal areas. This global experience informs our product development and ensures reliability in any installation scenario. With annual production capacity of 15GW and ranking among the top 5 global market share leaders, Grace Solar has the scale and expertise to support projects of any size and complexity.

Choosing the Right Mounting System

Selecting the appropriate aluminum rail system requires careful consideration of multiple factors to ensure optimal performance and return on investment. Making the right choice involves evaluating technical requirements, environmental conditions, and long-term maintenance considerations.

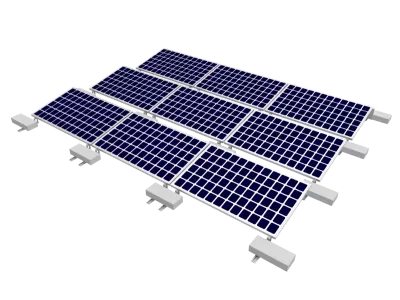

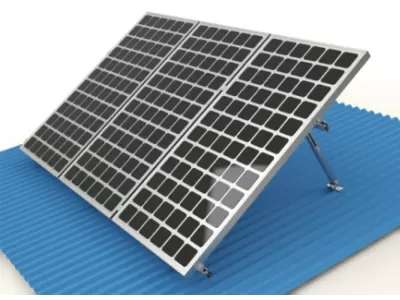

Roof Type Compatibility

Different roof materials require specific mounting approaches. Asphalt shingle roofs typically use flashed mounting feet, while metal roofs may employ standing seam clamps. Tile roofs often require specialized hooks, and flat roofs might use ballasted systems. Grace Solar offers compatible solutions for all common roof types, with our technical team providing customized recommendations based on your specific roof structure and local building code requirements.

Environmental Considerations

Local climate conditions significantly influence rail selection. High-wind areas require closer rail spacing and enhanced attachment methods. Coastal installations benefit from extra corrosion protection, while snowy regions need increased load capacity. Our technical team can provide specific recommendations based on your project location, including wind tunnel testing data and snow load calculations to ensure your system meets all safety and performance standards.

Future Expansion and Maintenance

When designing your solar mounting system, consider potential future expansion. Modular rail systems allow for easier addition of panels later. Also factor in maintenance accessibility and the potential need for roof repairs during the system's lifetime. Grace Solar's modular design philosophy ensures that our rail systems can be easily expanded or modified as your energy needs evolve, protecting your investment for years to come.

Professional Guidance Available

As a global leader with top 5 market share worldwide and number 1 position in the Japanese market, Grace Solar provides comprehensive technical support for project planning and installation. Our team of experienced engineers can assist with system design, load calculations, and compliance with local building codes. Explore our complete range of solar mounting rails and discover why professionals worldwide trust Grace Solar for their critical installations. With our "Do it right the first time" philosophy and commitment to quality, we ensure every installation meets the highest standards of performance and reliability.

/Adjustable%20solar%20ground%20mount%20system%20on%20snowy%20mountain%20with%2055%20Angle%20tilt_-400x300w.webp)

/Engineer%20assembling%20Grace%20Solar's%20portrait%20ground%20mount%20in%20typhoon%20area_-400x300w.webp)