Energy Storage Support Structure: The Complete Guide to BESS Frameworks

In the rapidly evolving battery energy storage system (BESS) landscape, the term "support structure" is pivotal, encompassing both the physical framework and the functional system architecture. For global project developers, EPCs, and asset owners, mastering both aspects is critical for ensuring safety, optimizing performance, and securing long-term return on investment. This comprehensive guide explores the multifaceted nature of energy storage support structures, highlighting how integrated engineering expertise is essential for successful project deployment.

Table of Contents

Part 1: The Physical Backbone – Frames, Enclosures & Environmental Protection

The physical support structure forms the tangible, engineered framework that ensures the mechanical integrity, safety, and 25-year lifespan of a BESS installation. It is the first line of defense against environmental, climatic, and operational stresses, directly impacting system uptime and total cost of ownership.

1.1 Battery Racks & Modular Enclosures

Battery cells are integrated into modules, which are then securely mounted into standardized racks. These racks are the primary building blocks, designed for precise weight distribution, structural stability, and often, seismic resilience. Modern racks feature smart design for passive fire suppression systems and easy maintenance access. They are housed within industrial-grade enclosures or containerized solutions that provide IP54-rated weatherproofing, security, and a primary layer of fire resistance. The choice between walk-in containerized solutions and modular cabinet-based systems depends on project scale, site layout, and local fire codes.

1.2 Engineered Mounting & Foundations

For both co-located solar-plus-storage and standalone BESS projects, the ground or rooftop mounting system is critical. It must be engineered for specific site conditions, accounting for dynamic wind loads (per ASCE 7, Eurocode, or AS/NZS1170), soil bearing capacity, seismic activity, and snow loads. Proper foundation design prevents settling and ensures long-term alignment. As a global leader in structural solutions for renewables with a cumulative 48GW installed worldwide, Grace Solar applies deep geotechnical and structural engineering expertise to BESS foundations, ensuring they are engineered to be "firm as rock" across diverse global terrains.

1.3 Integrated Thermal Management (HVAC)

This is a non-negotiable subsystem within the physical structure. Lithium-ion batteries perform optimally within a narrow temperature range (~15-25°C). An efficient thermal management system—utilizing air conditioning, liquid cooling, or phase-change materials—actively regulates temperature to prevent overheating (a critical risk for thermal runaway) and maintains efficiency in extreme cold, directly impacting cycle life, safety, and warranty conditions. Design must consider ambient climate, with solutions differing drastically for projects in the Middle East versus Scandinavia.

Part 2: The Operational Core – System Architecture & Components

Beyond the physical frame, the functional "support structure" refers to the integrated electrical and software components that manage energy flow, ensure safety, and enable grid services. This architecture is why lithium-ion systems dominate over 90% of new storage deployments.

Battery Management System (BMS)

The guardian of the battery pack. It monitors cell-level voltage, temperature, and state of charge (SOC) in real-time with precision. Its critical functions include active/passive cell balancing, protecting against over/under-voltage and short circuits, predicting state of health (SOH), and providing essential data to the Energy Management System (EMS). A robust, multi-tiered BMS is fundamental to safety, longevity, and unlocking advanced grid service capabilities.

Power Conversion System (PCS)

The system's translator and gateway. This bi-directional inverter converts DC from the batteries to AC for the grid/load and AC to DC for charging. Key specifications include efficiency (often >98%), response time, and harmonic distortion. The choice between AC-coupled (separate inverter, ideal for retrofits and flexible sizing) and DC-coupled (shared inverter with PV, often higher round-trip efficiency for new builds) is a primary design decision impacting project economics and performance.

Energy Management System (EMS) & SCADA

The brain for strategy, economics, and grid integration. Operating above the BMS and PCS, the EMS uses forecasting algorithms and market signals to control when to charge or discharge, optimizing for value streams like energy arbitrage, demand charge management, frequency regulation, or solar self-consumption. The SCADA (Supervisory Control and Data Acquisition) system provides the real-time monitoring, control interface, and data logging essential for asset management, remote operation, and compliance reporting.

Advanced Design Considerations for Modern BESS

Modern energy storage projects require forward-thinking design that goes beyond basic component selection.

Safety by Design: Fire Suppression & Ventilation

A comprehensive support structure integrates safety from the ground up. This includes dedicated fire detection systems (smoke, heat, gas), integrated fire suppression (e.g., aerosol, water mist, or chemical agents), and explosion venting panels. Proper ventilation design manages off-gassing risks and maintains air quality within enclosures, a critical factor for permitting and insurance.

Future-Proofing & Scalability

Modularity is key. Physical layouts and electrical busways should be designed to allow for cost-effective future capacity expansion (e.g., adding more battery racks) or technology upgrades. This involves planning for extra space, cable routing, and ensuring the PCS has unused capacity or is easily paralleled.

Navigating Global Standards & Compliance

A globally viable support structure must adhere to a complex web of international and local standards. Key certifications and codes include:

- Safety: UL 9540 (ESS Safety), UL 1973 (Batteries), UL 1642 (Cell Safety), IEC 62619.

- Grid Interconnection: IEEE 1547 (US), IEC 61727, G99/G100 (UK), VDE-AR-N 4105 (Germany).

- Building & Fire: NFPA 855 (ESS Installation), IFC, local building codes.

Engineering support structures for diverse markets requires deep regulatory insight. Providers with a global footprint, like Grace Solar, leverage experience from hundreds of MW installed across 100+ countries to navigate these requirements efficiently, avoiding costly redesigns and delays.

The Integrated Engineering Advantage

True system reliability and bankability are born from the seamless interaction between the physical and operational support structures. A flaw in either can cascade: inadequate thermal design can force the BMS to derate power or trigger shutdowns; a poorly designed cable management system can impede airflow and maintenance, increasing OPEX.

Engineering these elements in isolation is a significant project risk. This is where leveraging a provider with holistic expertise becomes critical. Drawing from our foundational experience as a top 5 global solar mounting specialist and the leader in the precision-driven Japanese market, we at Grace Solar understand structural dynamics, material science, electrical integration, and thermal performance as an interconnected system. Our 2000m² R&D center and 15GW annual production capacity allow us to prototype, validate, and deliver solutions where the enclosure, thermal management, component layout, and safety systems are co-optimized from the initial design phase.

Custom Energy Storage Support Structures for Global Projects

Every project presents unique challenges: constrained urban sites, extreme climates (desert heat, coastal salinity, alpine cold), specific grid operator requirements, or multi-technology hybrid systems. Off-the-shelf support structures often force compromises that affect performance or profitability.

Our approach is centered on custom-engineered solutions. We collaborate with clients to develop support structures that meet exact specifications:

- High-density racking for space-constrained sites.

- Corrosion-resistant materials and coatings for harsh environments.

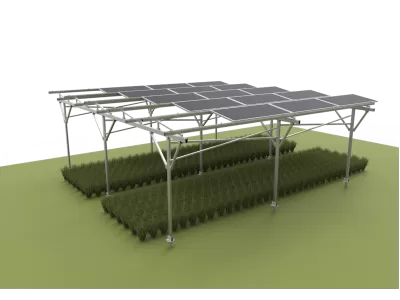

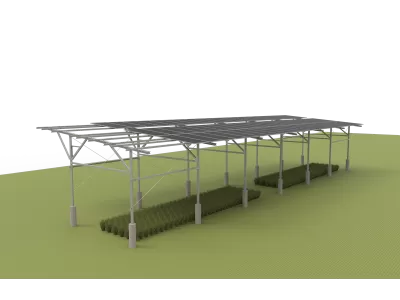

- Integrated designs for hybrid systems (e.g., BESS + solar carport).

- Foundations optimized for challenging soil conditions.

This consultative, engineering-led approach de-risks projects and ensures the support structure is an asset, not a constraint.

Ready to Build Your BESS on a Foundation of Global Expertise?

Whether you are in the early planning stages or need a solution for a specific site challenge, our engineering team is ready to support your vision for a safe, efficient, and high-performing energy storage system.

Contact Us for a Custom Consultation