Table of Contents

- Beyond the Shelf: Redefining Energy Storage Racks for Megawatt-Scale Projects

- The Structural Backbone: Why Specialized Engineering is Non-Negotiable

- A Suite of Comprehensive Solutions for the BESS Ecosystem

- Key Design and Specification Considerations for Your Project

- Building to Global Standards: Compliance and Certification

- Partnering for Project Success: From Consultation to Commissioning

Beyond the Shelf: Redefining Energy Storage Racks for Megawatt-Scale Projects

In the rapidly evolving energy landscape, the term **"Energy Storage Rack"** is often misunderstood. While consumer searches yield results for garage organizers or retail battery displays, the definition shifts dramatically within the realm of utility-scale and commercial & industrial (C&I) energy infrastructure. Here, an **Energy Storage Rack System** refers to the critical, engineered structural framework designed to support, secure, and protect multi-megawatt Battery Energy Storage Systems (BESS).

These are not passive shelves but active safety components. A single 20-foot or 40-foot BESS container can weigh between 20 to 40 tons when fully loaded with battery modules, power conversion systems, and climate control. The rack system is the unsung hero that ensures this high-value asset remains stable through decades of operation, resisting environmental extremes, facilitating maintenance, and optimizing performance. Drawing on extensive experience from companies like Grace Solar, which has engineered support structures for over 48GW of global renewable projects, this article explores the engineering rigor behind these foundational systems.

The Structural Backbone: Why Specialized Engineering is Non-Negotiable

The support structure is the first line of defense for a multi-million-dollar storage investment. Its failure could lead to catastrophic asset damage, safety hazards, and significant financial loss. Professional engineering addresses four interconnected pillars of performance:

- Extreme Load Management & Dynamic Stability: Systems must be calculated for site-specific design wind speeds (often exceeding 46 m/s, equivalent to a Category 2 hurricane), seismic activity per local codes, and heavy snow loads. They manage not just static weight but also dynamic forces from wind gusts, potential seismic events, and thermal expansion/contraction over a 20-30 year lifespan.

- Corrosion Defense for Harsh Environments: BESS sites are often located in challenging environments—coastal areas with salt spray, deserts with abrasive sand, or industrial zones. Utilizing high-grade, hot-dip galvanized or zinc-aluminum-magnesium (ZAM) coated steel (like Q355 or S420GD) is essential to prevent rust and structural degradation, ensuring longevity with minimal maintenance.

- Passive Thermal Management Integration: Battery performance and lifespan are highly temperature-sensitive. Engineered rack designs can incorporate strategic elevation for under-container airflow or, more effectively, integrated solar canopies. These canopies, built using systems like the C.S Container Top Mount, provide shade that can reduce container surface temperatures significantly, lowering active cooling energy consumption (parasitic load) by 10-20% and directly improving system efficiency and battery cycle life.

- Logistical & Installation Precision: Time on-site is money. Pre-engineered, modular rack systems with clear assembly protocols enable rapid, bolt-together installation. This reduces labor costs, minimizes weather-dependent delays, and eliminates the need for specialized welding or heavy concrete curing times associated with traditional foundations.

A Suite of Comprehensive Solutions for the BESS Ecosystem

A successful energy storage site requires a holistic structural approach that goes beyond merely holding containers off the ground. It involves integration, site optimization, and addressing ancillary challenges like noise and security. The following represents a mature product suite designed to cover the full spectrum of BESS infrastructure needs.

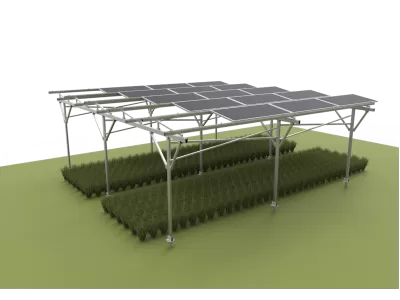

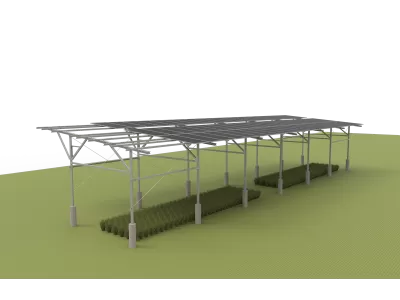

1. G58 Heavy-Duty Ground-Mount Support System: The Primary Foundation

Core Function & Applications: The primary structural foundation for arrays of battery storage containers, transformer pads, and power conversion skids in utility-scale farms or large C&I installations.

Engineering Advantages & Design Features:

• **High-Strength Fabrication:** Constructed from H-beams and I-beams (Q235/Q355), offering superior load-bearing capacity and torsional rigidity compared to simple C-channel designs.

• **Non-Penetrating, Flexible Foundation:** Often utilizes ballasted or micro-pile foundations that minimize ground disturbance, are adaptable to varied soil conditions, and allow for easier decommissioning or relocation.

• **Integrated Cable Management:** Designed with raceways or dedicated channels to safely route and protect medium-voltage (MV) and communication cabling between units, improving site safety and aesthetics.

• **Corrosion-Resistant Finish:** Hot-dip galvanizing provides a durable barrier against environmental corrosion for a decades-long service life.

2. C5 Acoustic Barrier & Integrated Wind Screen System: Mitigating Site Impact

Core Function & Applications: A dual-purpose perimeter system that mitigates operational noise from inverters and transformers to comply with local ordinances, while also providing wind load protection for equipment and dust control.

Engineering Advantages & Design Features:

• **Noise Reduction Engineering:** Incorporates mass-loaded vinyl or composite acoustic panels within a robust steel frame (Q355) to achieve specified Sound Transmission Class (STC) ratings, often required for permits in residential-adjacent or noise-sensitive areas.

• **Structural Windbreak:** Reduces wind speed across the storage array, which can lower the dynamic wind load on the containers themselves and minimize dust and debris accumulation on cooling vents.

• **Security & Aesthetics:** Creates a defined site boundary, enhances security, and presents a clean, professional appearance to the public and stakeholders.

• **Durable Construction:** Finished with enhanced paint systems or ZAM coatings on aluminum components for long-term weather resistance.

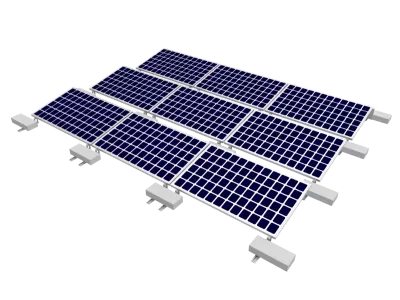

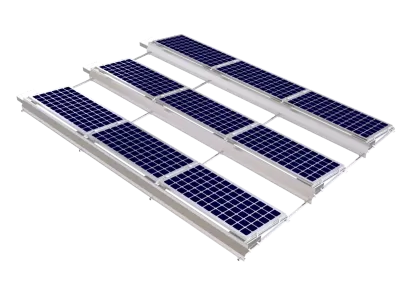

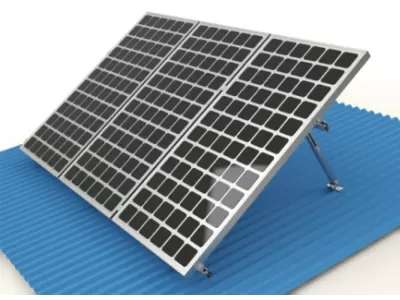

3. C.S Container Top Mounted Solar Rack System: The Efficiency Multiplier

Core Function & Applications: Mounts photovoltaic (PV) panels directly onto the roofs of BESS containers, creating a "solar canopy" that generates on-site power while providing critical shade.

Engineering Advantages & Design Features:

• **Thermal Load Reduction:** The primary function is shading. By blocking direct solar irradiation, the system dramatically reduces the thermal load on the container, lowering the energy required for air conditioning and extending the life of sensitive battery cells.

• **Energy Yield & Land Use Efficiency:** Generates clean electricity that can directly offset the facility's parasitic load or be fed into the storage system, improving overall economics. It represents ultimate land-use efficiency by combining generation and storage in the same footprint.

• **Non-Penetrating, Weight-Distributed Design:** Engineered to attach securely to the container's factory-approved lift points or structural frame without penetrating the roof membrane, preserving warranty. Weight is evenly distributed to avoid point loads.

• **Aerodynamic Profile:** Designed with a low tilt angle and streamlined profile to minimize additional wind uplift forces on the container.

Key Design and Specification Considerations for Your Project

Selecting and specifying the correct energy storage rack system is a collaborative process that requires input from developers, EPCs, and structural engineers. Key factors to define early include:

- Site Due Diligence Data: Provide geotechnical reports (soil bearing capacity), certified climate data (50-year wind speed, seismic zone, snow load), and topographical surveys.

- BESS Container OEM Specifications: Exact dimensions, weight (tare and gross operational), center of gravity, locations of lift points, forklift channels, and door swing clearances are critical for custom design.

- Site Layout & Master Planning: Account for required spacing between containers for fire safety (as per NFPA 855 or local equivalents), maintenance access, utility corridor routing, and crane reach.

- Future Expansion Strategy: Design the foundation and layout with a master plan in mind. Modular rack systems should allow for the cost-effective addition of more containers in future phases without major site rework.

- Local Authority Having Jurisdiction (AHJ) Requirements: Understand all applicable building codes, fire department review requirements, stormwater management rules, and any specific energy storage system regulations.

Building to Global Standards: Compliance and Certification

For international project finance and insurance, structural components must meet the highest standards of quality and safety. Reputable manufacturers design and document their systems to comply with a rigorous framework:

- International Structural Design Codes: Designs are calculated per ASCE 7 (Americas), Eurocode (EN 1993), or other regional standards for wind, seismic, and dead loads. This ensures global applicability and bankability.

- Material Traceability & Certification: All structural steel is sourced with mill test certificates (MTCs) confirming compliance with ASTM, EN, JIS, or GB standards for chemical composition and mechanical properties.

- Corrosion Protection Standards: Hot-dip galvanizing is performed per ASTM A123 or ISO 1461, with specified coating thicknesses measured and documented to ensure decades of protection.

- Independent Professional Engineer (P.E.) Stamp: Final structural calculations and fabrication drawings are reviewed and stamped by a licensed Professional Engineer. This stamped set is mandatory for permit submissions and provides liability assurance.

- Quality Management Systems: Manufacturing within an ISO 9001-certified facility guarantees consistent quality control processes from raw material to finished product.

Partnering for Project Success: From Consultation to Commissioning

The complexity of modern BESS projects demands a partnership model with your structural supplier. Moving beyond a simple transactional purchase to an engineered solution partnership mitigates risk and streamlines the critical path. The ideal collaboration follows a phased approach:

- Pre-Design & Feasibility Support: Early engagement allows for optimizing site layouts for structural efficiency, advising on foundation choices, and providing budgetary pricing to support financial models.

- Custom Engineering & Documentation: Based on final site data and container specs, the provider delivers a complete custom design package, including stamped PE drawings, a full bill of materials, and detailed assembly instructions.

- Precision Manufacturing & Logistics: Components are fabricated in a controlled factory environment using CNC machinery for precision, then kitted, labeled, and packaged for efficient shipment to any global port.

- Commissioning Support & Warranty: Reputable partners offer support during the installation phase and back their products with a substantial structural warranty (e.g., 10+ years), aligning with the project's long-term operational horizon.

Leveraging a partner with a proven track record in large-scale renewable infrastructure, such as Grace Solar, brings this disciplined, engineering-first mindset to your energy storage project. It ensures that the physical foundation of your storage asset is engineered with the same rigor as the electrochemical systems it supports.

Engineer a Solid Foundation for Your Storage Project

Connect with our engineering team to discuss your specific site requirements, container specifications, and project goals. We provide end-to-end custom energy storage support structure solutions backed by global project experience.

Request a Custom Engineering Consultation