Table of Contents

What is a Standing Seam Solar Mount?

A standing seam solar mount represents the gold standard in metal roof solar installations, offering a sophisticated mounting solution specifically engineered for standing seam metal roofs. Unlike conventional roofing materials that necessitate penetrations, these advanced mounting systems utilize specialized clamps that attach directly to the vertical seams of metal roofs, completely eliminating the need for drilling and preserving the roof's waterproof integrity for decades.

The Core Components Explained

A comprehensive standing seam mounting system typically includes precision-engineered seam clamps, high-strength mounting rails (for rail-based configurations), mid-clamps, end-clamps, and compatible L-feet or direct attachment points. These components work synergistically to create a secure, weather-tight connection capable of withstanding extreme environmental conditions while maintaining structural integrity. The clamps are specifically designed to distribute load evenly across the seam, preventing stress concentration points that could compromise the roof structure.

Compatible Roof Profiles

Standing seam mounting systems are compatible with various metal roof profiles including mechanical seam, snap-lock, and nail strip configurations. These systems can accommodate seam heights ranging from 1.0" to 2.5" and are suitable for most common standing seam roof types found in commercial, industrial, and residential applications worldwide. The versatility of modern clamping systems ensures compatibility with major roofing manufacturers' profiles without requiring custom fabrication.

How Does Standing Seam Mounting Work?

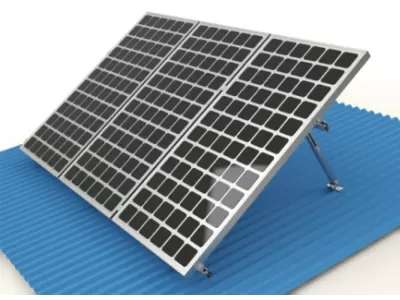

The fundamental engineering principle behind standing seam solar mounts centers on their innovative non-penetrating attachment methodology. Specially engineered clamps employ advanced mechanical principles to grip the vertical seams of metal roofs securely without compromising the roof surface or protective coatings. This sophisticated approach offers substantial advantages over traditional mounting methods, particularly in preserving roof warranties and extending system lifespan.

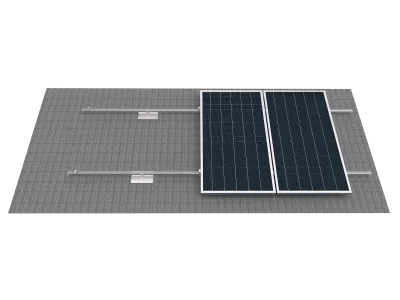

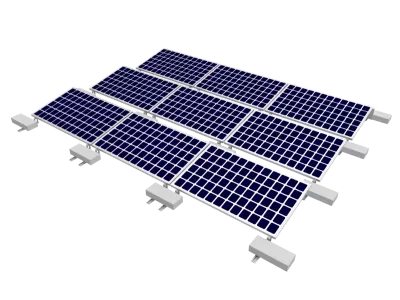

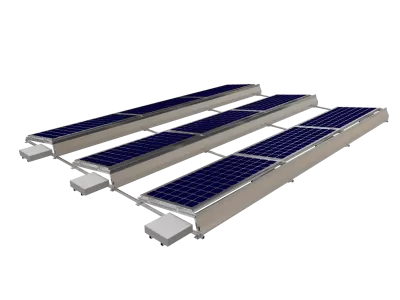

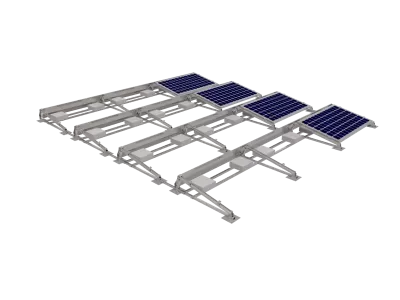

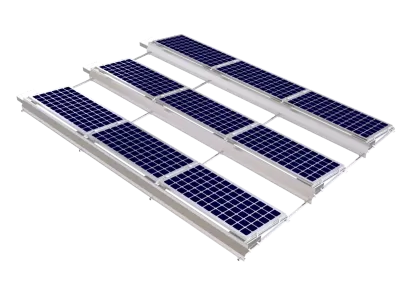

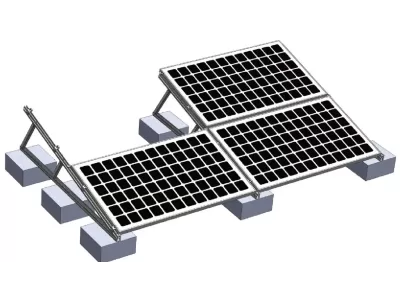

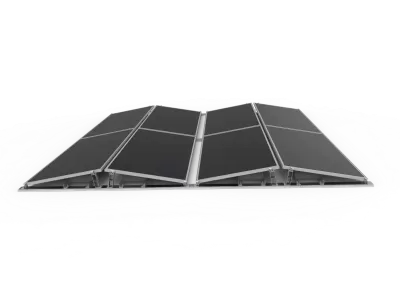

Rail-Based vs. Rail-Less Systems: A Detailed Comparison

The solar industry primarily utilizes two distinct approaches to standing seam mounting: traditional rail-based systems that employ conventional mounting rails, and innovative rail-less systems where solar panels attach directly to specialized mounting hardware. Rail-less systems demonstrate remarkable efficiency, reducing total system weight by up to 85% and significantly decreasing installation time by eliminating multiple assembly steps. Conversely, rail-based systems provide superior flexibility in panel positioning, alignment precision, and often accommodate wider panel size variations. The choice between systems depends on project-specific requirements including roof load capacity, installation timeline, budget constraints, and aesthetic considerations.

Advanced Clamping Technology

Modern standing seam clamps incorporate sophisticated engineering features including progressive clamping mechanisms, anti-slip surface treatments, and corrosion-resistant materials. Many premium clamps feature pre-installed set screws and color-matched components for enhanced aesthetics. The clamping force is carefully calibrated to secure the mounting system without deforming the roof seams or compromising the structural integrity of the metal panels, ensuring long-term reliability and performance.

Key Benefits of Standing Seam Solar Mounts

Zero Roof Penetration Guarantee

The most significant advantage remains the complete elimination of roof penetrations. This crucial feature preserves original roof warranties, prevents potential leaks throughout the system's lifespan, and maintains the structural integrity of the entire roofing system. By avoiding penetrations, building owners eliminate the risk of water infiltration, corrosion at fastener points, and thermal bridging that can compromise building envelope performance.

Superior Wind Resistance Performance

Properly engineered standing seam mounts undergo rigorous testing to withstand wind speeds exceeding 60 m/s (134 mph), making them ideal for hurricane-prone regions and high-wind applications. The seamless integration with the roof structure creates a unified system that resists uplift forces more effectively than penetrating mounts. Third-party testing and certification validate these performance characteristics, providing engineers and building owners with confidence in extreme weather conditions.

Reduced Installation Time & Labor Costs

Pre-assembled components, simplified clamping mechanisms, and intuitive installation processes can reduce total installation time by 30-50% compared to traditional penetrating systems. The efficiency gains translate directly to lower labor costs, reduced on-site coordination challenges, and minimized business disruption for commercial installations. Many systems feature tool-less or single-tool installation, further streamlining the process.

Long-Term Durability & Maintenance Advantages

Constructed from premium corrosion-resistant materials including aluminum 6005-T5 and stainless steel A2-70, these systems are engineered to match or exceed the 25+ year lifespan of modern solar panels. The non-penetrating design eliminates common failure points associated with roof penetrations, significantly reducing long-term maintenance requirements and costs. Additionally, systems can be easily removed and reinstalled for roof maintenance or panel upgrades.

Enhanced Energy Production & Roof Protection

The elevated design of standing seam mounts promotes superior air circulation beneath panels, reducing operating temperatures and potentially increasing energy production by 2-5% compared to directly attached systems. Simultaneously, the mounting system provides protective shading to the roof surface, which can reduce rooftop temperatures and extend roof membrane life, creating additional value beyond energy generation.

Installation Process Overview

Step 1: Comprehensive Roof Assessment & Engineering Planning

Before installation commences, conduct a thorough roof inspection to verify proper seam integrity, assess load capacity, and identify any potential issues. Professional engineers calculate optimal clamp spacing based on structural requirements, local building codes, and specific environmental conditions. This phase includes detailed measurement of seam profiles, verification of roof panel fastening, and assessment of existing roof condition to ensure compatibility with the planned solar array.

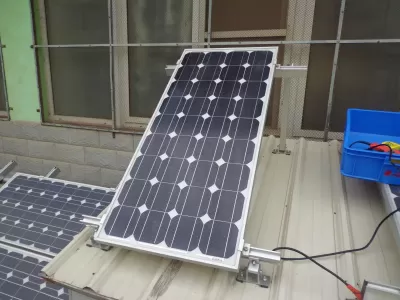

Step 2: Precision Clamp Installation

Position specialized clamps onto the vertical seams at predetermined intervals according to engineering specifications. Utilize torque wrenches to tighten fasteners to manufacturer-recommended values, ensuring secure attachment without damaging the seams or compromising the roof coating. Proper installation technique is critical to distribute loads evenly and prevent point loading that could deform seams over time.

Step 3: Mounting System Assembly & Alignment

Attach rails or direct-mount brackets to the installed clamps, ensuring precise alignment and leveling across the entire array. Implement quality control checks at this stage to verify proper spacing, orientation, and structural integrity. For rail-based systems, ensure continuous support and proper engagement of all connection points to maintain system rigidity and performance.

Step 4: Panel Installation, Wiring & Commissioning

Mount solar panels to the completed racking system using manufacturer-specified hardware and techniques. Perform all necessary electrical connections following NEC standards and local electrical codes. Complete system commissioning includes verification of mechanical integrity, electrical safety, performance validation, and documentation for warranty and maintenance purposes.

Grace Solar Standing Seam Solutions

With over a decade of specialized experience and a position among the top 5 in global market share, Grace Solar has pioneered advanced standing seam mounting solutions that combine engineering excellence with practical installation benefits. Our global cumulative installed capacity of 48GW demonstrates our proven track record in delivering reliable, high-performance solar mounting systems across diverse applications worldwide. The company's 650 dedicated professionals and 110,000m² manufacturing facility ensure consistent quality and timely delivery for projects of any scale.

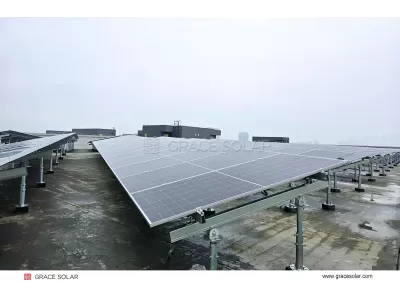

Engineered for Global Applications & Extreme Conditions

Our standing seam mounts undergo extensive research and development to perform optimally in diverse climatic conditions, from the harsh winters of Northern Europe to the tropical environments of Southeast Asia. With successful installations in over 100 countries, our systems are tested and proven across all major climate zones and seismic regions. Each system incorporates regional-specific engineering considerations to address local environmental challenges and regulatory requirements.

Innovative Design Features & Technological Advancements

Grace Solar's standing seam solutions incorporate patented clamping technology that ensures even pressure distribution across the seam, preventing damage while maintaining maximum holding power. Our pre-assembled components reduce installation time and minimize on-site errors. The integration of AI-assisted design tools and automated manufacturing processes guarantees precision engineering and consistent quality across all product lines. Our 2,000m² experiment center continuously tests and validates new designs under simulated extreme conditions.

Comprehensive Project Support Services

Beyond manufacturing excellence, Grace Solar provides comprehensive project support including engineering consultation, customized design services, installation training, and technical documentation. Our global network of support professionals ensures responsive service and expert guidance throughout project lifecycle from initial planning to long-term maintenance.

Technical Specifications & Certifications

Material Excellence & Quality Assurance

All Grace Solar standing seam components utilize premium materials including AL6005-T5 aluminum extrusions and stainless steel A2-70 fasteners, providing exceptional corrosion resistance and structural integrity. Our manufacturing processes incorporate rigorous quality control measures at each production stage, ensuring dimensional accuracy and material consistency. Advanced surface treatments including architectural anodizing and powder coating options provide enhanced durability and aesthetic appeal.

Comprehensive Global Certifications

Our standing seam mounting systems have achieved comprehensive international certifications including UL 2703, TUV, CE, JIS, MCS, and comply with AS/NZS1170 standards. These certifications ensure compliance with the strictest global building and safety codes. Regular third-party audits and testing validate ongoing compliance with evolving international standards, providing specifiers and building owners with confidence in system safety and performance.

Performance Specifications & Load Capacity

Wind Load: Up to 60 m/s (134 mph) tested in accordance with ASTM E1592

Snow Load: Up to 1.4 kN/m² (29.2 psf) with options for higher capacity

Seismic Compliance: Designed to meet IBC and ASCE 7 requirements for seismic zones

Temperature Range: -40°C to +80°C operational capability

Design Life: 25+ years with proper maintenance

Corrosion Resistance: Salt spray testing exceeding 3,000 hours per ASTM B117

Global Applications & Case Studies

Commercial & Industrial Project Excellence

Grace Solar's standing seam systems have been deployed on large-scale commercial warehouses, manufacturing facilities, and big-box retail centers across North America, Europe, and Asia. Our solutions are particularly valued for their rapid installation and minimal business disruption. Notable projects include multi-megawatt distribution centers where installation efficiency directly impacted project economics and operational timelines. The scalability of our systems supports projects ranging from small commercial retrofits to utility-scale installations exceeding 100 MW.

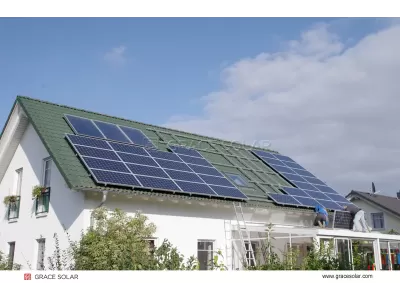

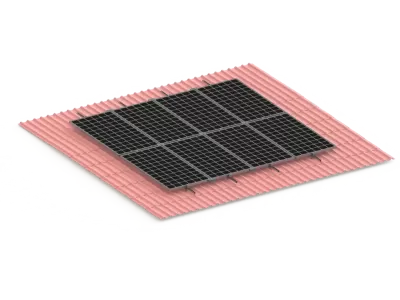

Residential Excellence & Market Leadership

With the #1 market share in Japan for residential solar mounting, our standing seam solutions bring commercial-grade reliability to residential applications, offering homeowners peace of mind and superior system longevity. The aesthetic integration of our systems with premium residential architecture has established new standards for solar installation quality in the luxury home market. Our residential solutions prioritize both performance and visual appeal, with color-matched components and low-profile designs.

International Success Stories & Technical Achievements

From Australian coastal installations facing salt spray corrosion challenges to European projects requiring heavy snow load capacity, Grace Solar's standing seam mounts have consistently delivered exceptional performance across diverse global conditions. In Middle Eastern applications, our systems have demonstrated superior performance in high-temperature environments, while Scandinavian installations have validated our cold-climate durability. Each successful project contributes to our growing database of performance validation and technical refinement.

System Selection Guide

Project Evaluation Criteria

Selecting the appropriate standing seam mounting system requires careful consideration of multiple factors including roof condition, structural capacity, local climate conditions, project budget, and aesthetic requirements. Professional assessment should include detailed measurement of seam profiles, evaluation of existing roof fastening systems, and analysis of historical performance data for similar applications. The integration of building-specific data with regional climate information ensures optimal system selection and configuration.

Technical Compatibility Assessment

Comprehensive compatibility analysis includes verification of clamp-to-seam interface, assessment of structural loading capacity, and evaluation of thermal expansion characteristics. Engineering review should confirm adequate factor of safety margins, appropriate material compatibility, and compliance with all applicable building codes and standards. Third-party review and validation may be recommended for complex projects or innovative applications.

As an industry leader in solar mounting solutions with 650 dedicated staff and 110,000m² manufacturing facility, Grace Solar continues to drive innovation in standing seam technology through substantial R&D investment and continuous product improvement. Our commitment to "Mount every solar plant firm as rock" and core value of "Do it right the first time" ensures that your investment in solar energy is supported by the most reliable, thoroughly tested mounting solutions available in the global market. With annual production capacity of 15GW and growing international presence, we remain dedicated to advancing solar technology while maintaining the highest standards of quality and performance.