Table of Contents

- Materials: Determining Performance

- Process: The Key to Quality

- Anti-Corrosion: Ensuring Long-Term Service

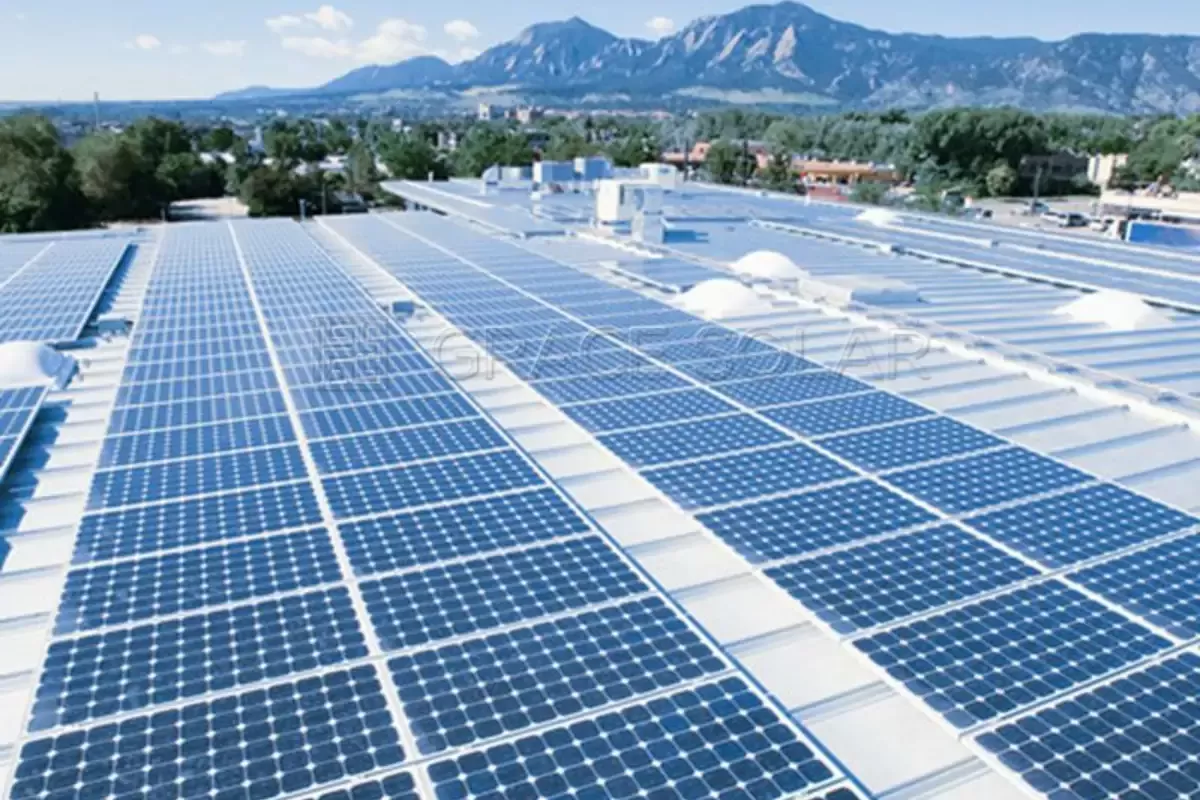

The intrinsic quality of a solar mounting system is often hidden beneath the surface—determined by the choice of materials, the precision of manufacturing processes, and the robustness of anti-corrosion protection. At Grace Solar, a global leader ranking among the top 5 worldwide, we subject our systems to rigorous performance limit testing to ensure they withstand the harshest conditions. This report delves into the core pillars defining the durability and reliability of modern solar mounting solutions, with a focus on rooftop applications.

Materials: Determining Performance

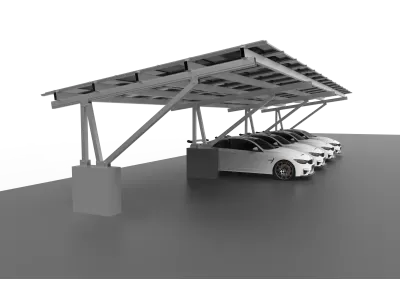

The foundational choice of material for photovoltaic mounting systems directly dictates their structural strength, longevity, and optimal application scenarios. For rooftop installations, this decision becomes even more critical due to weight constraints and building integration requirements. Aluminum alloy mounting systems excel in these environments. Their lightweight nature, inherent corrosion resistance, and ease of fabrication make them the preferred choice for rooftop distributed PV, carports, and BIPV (Building-Integrated Photovoltaics) projects. While their material cost is typically higher than steel, the savings in structural support and installation complexity deliver significant value for rooftop applications. Steel, with its superior strength, is also used in heavy-duty commercial rooftop setups where structural capacity is paramount.

Leveraging over a decade of global project experience with a cumulative installed capacity of 48GW, Grace Solar provides expert material selection guidance. Our engineers analyze specific rooftop conditions—including wind uplift forces, snow loads, and roof membrane types—to recommend the most performant and economical material for each project, ensuring optimal performance of our GS-Energy roof systems.

Process: The Key to Quality

Superior materials alone are not enough; it is the manufacturing and connection processes that transform them into a reliable, unified structure specifically engineered for rooftop challenges. The integrity of a solar mounting system hinges on its connection points, which must accommodate thermal expansion, resist vibration, and maintain waterproofing. At Grace Solar, we invest heavily in advanced process technology. Our 110,000 m² manufacturing facility and dedicated 2,000 m² R&D and experiment center allow for stringent process control. From the precision cutting of aluminum extrusions to the specialized coating of steel components, every step is monitored to ensure consistency.

Rooftop systems require particular attention to installation efficiency and roof protection. Our connection systems are designed for rapid, tool-friendly assembly while maintaining structural integrity. This commitment, backed by a team of highly sophisticated engineers and over 100 patents, ensures that every connection maintains exceptional performance and long-term reliability, a principle embodied in our core value: “Do it right the first time.” This approach minimizes roof penetration risks and ensures the mounting system works in harmony with the building structure.

Anti-Corrosion: Ensuring Long-Term Service

Corrosion is a critical concern for rooftop mounting systems exposed to diverse weather conditions, including rain, humidity, and temperature fluctuations. Therefore, the anti-corrosion rating is a paramount indicator of a mounting system's durability and its ability to protect both the solar array and the roof structure over 25+ years. International standards such as ISO 12944, ASTM, and GB/T provide clear frameworks, defining protective requirements for different corrosivity categories.

Effective corrosion protection for rooftop systems is a holistic system engineering effort. It encompasses everything from alloy selection and coating specifications to design features that prevent water pooling and galvanic corrosion between dissimilar metals. Grace Solar products undergo rigorous multi-layered validation. Our rooftop systems carry globally recognized certifications like UL, TUV, and CE, which include strict anti-corrosion protocols. This ensures long-lasting and stable protective performance, safeguarding rooftop investments from coastal salt spray to industrial pollution.

As rooftop solar applications continue to expand across residential, commercial, and industrial buildings, Grace Solar remains at the forefront of mounting system innovation. We are committed to advancing our rooftop products toward greater installation efficiency, lighter weight for reduced structural load, and higher weather resistance for all climates. Guided by our mission to “mount every solar plant firm as rock,” we provide the trustworthy products and services that ensure green energy infrastructure stands the test of time on rooftops worldwide. For custom solar mounting solutions tailored to your specific rooftop project requirements, please contact our engineering team for a detailed consultation.

/Aluminum%20alloy%20solar%20ground%20mount%20system%20for%20residential%20solar%20panels-400x300w.webp)

/Modular%20ground-mounted%20solar%20structure%20with%20corrosion-resistant%20coating-400x300w.webp)

/W-Type%20aluminum%20solar%20mounting%20system%20structural%20detail-400x300w.webp)

/Ground%20screw%20foundation%20installation%20for%20Grace%20Solar%20racking-400x300w.webp)

/Adjustable%20solar%20ground%20mount%20system%20on%20snowy%20mountain%20with%2055%20Angle%20tilt_-400x300w.webp)

/Engineer%20assembling%20Grace%20Solar's%20portrait%20ground%20mount%20in%20typhoon%20area_-400x300w.webp)

/ZAM-coated%20steel%20components%20for%20corrosion-resistant%20solar%20racking_-400x300w.webp)

/Double-column%20aluminum%20solar%20ground%20mounting%20system%20for%20large-scale_-400x300w.webp)

/Al-Zn-Mg%20coated%20piling%20structure%20for%20extreme%20weather%20resistance_-400x300w.webp)

/Double-column%20carbon%20steel%20solar%20ground%20mount%20system%20with%20portrait%20panel%20arrang_-400x300w.webp)

/Aluminum%20alloy%20solar%20ground%20mount%20system%20installation%20on%20residential%20property_-400x300w.webp)

/Close-up%20of%20anodized%20aluminum%20clamp%20connection%20in%20ground%20mounting%20system_-400x300w.webp)

/Aluminum%20Alloy%20Solar%20Panel%20Ground%20Mount%20Frame_-400x300w.webp)

/Adjustable%20Tilt%20Ground%20Mount%20Solar%20Racking%20System_-400x300w.webp)

/Grace%20Solar%20ground%20mount%20installation%20on%20concrete%20foundation%20with%20rail%20clamps_-400x300w.webp)

/Aluminum%20alloy%20solar%20ground%20mounting%20system%20portrait%20placement%20for%20495W%20panels_-400x300w.webp)