Table of Contents

Introduction: Beyond the Panels

In the operation and maintenance (O&M) of photovoltaic (PV) power plants, while attention is often drawn to the gleaming solar panels and sophisticated inverters, few notice the silent steel structures that support the entire system. These metal frameworks, which may seem simple at first glance, are actually the cornerstone for long-term stable operation and financial returns. As a leader in smart solar mounting solutions, Grace Solar understands that the mounting system is the unsung hero of any successful solar project.

Take GraceSolar’s GS-Light intelligent tracking system as a prime example: its AI-driven real-time tilt optimization has the proven ability to boost power generation by 15% - 30%, fundamentally redefining the traditional concept that "mounting systems are merely passive support structures." This innovation stems from our commitment to integrating AI, IoT, and advanced mechanical engineering, backed by over 100 patents and a global cumulative installed capacity of 48GW.

The strategic importance is underscored by data. According to the latest report from the International Energy Agency (IEA), the average amount of global power generation losses caused by mounting system problems reaches 3.7%, and can even spike to 8% in harsh environments. For a large-scale plant, this translates to millions of dollars in lost revenue. This underestimated figure is a powerful reminder for developers and O&M teams to reevaluate the mounting system not as a commodity, but as a critical asset within the PV ecosystem.

Mounting Systems: The "Barometer" of Plant Health

Although modern PV mounting systems have evolved into intelligent solutions integrating mechanical engineering, materials science, and IoT technology, ensuring their health remains paramount. Most operational systems still require vigilant monitoring of structural stability. Standard O&M protocols rely on several fundamental, yet crucial, health monitoring methods:

- Periodic bolt torque rechecks (using calibrated torque wrenches, typically covering the entire plant on a quarterly basis).

- Visual inspections for foundation settlement (using precise level gauges, with an industry error threshold often set at ±3 cm).

- Manual corrosion checks on steel structures (focusing intensively on welds and mechanical connectors before and after the rainy season).

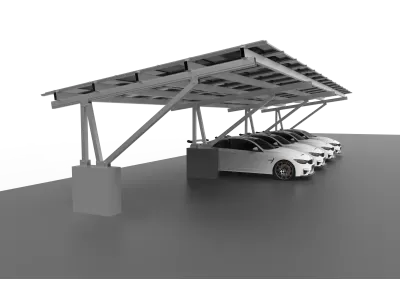

Figure: A Grace Solar ground mounting system deployed in a hybrid energy park, showcasing robust engineering for challenging environments.

Neglecting these basics can be catastrophic. A cautionary case from a 200 MW Southeast Asian power plant highlights the severe consequences of ignoring a mere 5 cm foundation settlement. This minor issue triggered a chain reaction leading to widespread array misalignment, resulting in an annual power loss of 5.2%, and direct financial losses exceeding $1.2 million. This starkly illustrates why Grace Solar's core value of "Do it right the first time" in engineering and installation is non-negotiable for long-term profitability.

Environmental Adaptability: Tailored Protection Strategies

A one-size-fits-all approach fails in solar O&M. The true test of a mounting system lies in its adaptability to local environmental stressors. Innovative O&M teams worldwide are developing bespoke strategies that set new benchmarks.

Figure: A 528KW ground mount installation by Grace Solar in New Zealand, engineered for high wind loads and variable climate conditions.

In a desert plant in Dubai, for instance, the O&M team developed a sophisticated "dust index-cleaning cycle" algorithm. This system predicts optimal rail maintenance and cleaning timing based on real-time weather and satellite dust data, preventing abrasion and energy loss. Meanwhile, at a challenging offshore PV project in China’s East China Sea, engineers innovated with graphene-based anti-corrosion coatings, successfully extending critical maintenance intervals from 3 to 18 months and drastically reducing O&M costs.

The Grace Solar Engineering Philosophy: Precision Adaptation

Drawing from hundreds of MW of project experience across over 100 countries, Grace Solar has institutionalized this adaptive approach. Our team of highly sophisticated engineers, many with international project experience, operates from a fully equipped 2000m² experiment center to develop and validate solutions. We provide cost-effective, yet superior, adaptive engineering for extreme environments:

- High-Salt Coastal Zones: We specify and apply robust two-component epoxy resin coatings combined with a mandatory annual comprehensive anti-corrosion inspection protocol to combat relentless salt spray.

- Permafrost Zones: Our designs employ deep-pile foundation techniques, ensuring structures are buried at least 1.5 meters below the frost line to prevent heaving and maintain stability through freeze-thaw cycles.

- High-Wind Regions: Leveraging wind tunnel test reports and certifications like AS/NZS1170, our designs incorporate specific ballasting, spacing, and reinforcement strategies to meet the most stringent wind load requirements.

Lean O&M: Optimizing Techniques for Maximum Yield

While technology advances, the fundamentals of diligent O&M remain incredibly powerful. Industry research consistently shows that simply strengthening manual inspection protocols and executing disciplined preventive maintenance can reduce sudden structural failures by over 30%. As the IEA report notes: "The potential of traditional mounting systems remains underutilized; systematic O&M management can deliver significant efficiency gains."

Figure: Detailed view of a durable carbon steel ground mounting system installed in a 656KW project in Morocco, demonstrating precision engineering for long-term stability.

This aligns perfectly with Grace Solar's mission to "Mount every solar plant firm as rock, bring more profits from the sun." Our products, from the GS-Smart ground mount to the GS-Energy roof system, are engineered for O&M simplicity and durability. With global certifications including UL, TUV, CE, JIS, and MCS, as well as bankability reports for our GS-Light tracker, we provide the reliability that forms the basis for lean, effective O&M. This reliability has established long-term strategic partnerships with many global Fortune 500 companies.

Conclusion: The Foundation of Solar Success

As the global PV industry advances relentlessly toward high-quality development and grid parity, the focus inevitably shifts to total lifecycle cost and energy yield. In this context, Grace Solar's mounting systems—with their solid engineering foundation, continuous innovation, and proven O&M advantages—serve as the silent guardians ensuring plant stability and investor returns. Our vision to "Bring Grace Solar to all homes" is built on this foundation of trust and performance.

The lesson is clear: The most reliable technology isn’t always the most cutting-edge, but the most robust and suited to its environment. The mounting system, therefore, is far from "invisible"; it is the critical backbone that determines the success and profitability of any solar power plant over its 25+ year lifespan.

Looking for a mounting solution that prioritizes long-term O&M efficiency and stability? Grace Solar, ranked among the top 5 globally in market share and #1 in Japan, offers tailored smart mounting and tracking systems. With an annual production capacity of 15GW and a commitment to being the "Most trustworthy products and service," we deliver solutions for DSP and CSP markets worldwide.

Contact Us for a Custom Solution

/Aluminum%20alloy%20solar%20ground%20mount%20system%20for%20residential%20solar%20panels-400x300w.webp)

/Modular%20ground-mounted%20solar%20structure%20with%20corrosion-resistant%20coating-400x300w.webp)

/W-Type%20aluminum%20solar%20mounting%20system%20structural%20detail-400x300w.webp)

/Ground%20screw%20foundation%20installation%20for%20Grace%20Solar%20racking-400x300w.webp)

/Adjustable%20solar%20ground%20mount%20system%20on%20snowy%20mountain%20with%2055%20Angle%20tilt_-400x300w.webp)

/Engineer%20assembling%20Grace%20Solar's%20portrait%20ground%20mount%20in%20typhoon%20area_-400x300w.webp)

/ZAM-coated%20steel%20components%20for%20corrosion-resistant%20solar%20racking_-400x300w.webp)

/Double-column%20aluminum%20solar%20ground%20mounting%20system%20for%20large-scale_-400x300w.webp)

/Al-Zn-Mg%20coated%20piling%20structure%20for%20extreme%20weather%20resistance_-400x300w.webp)

/Double-column%20carbon%20steel%20solar%20ground%20mount%20system%20with%20portrait%20panel%20arrang_-400x300w.webp)

/Aluminum%20alloy%20solar%20ground%20mount%20system%20installation%20on%20residential%20property_-400x300w.webp)

/Close-up%20of%20anodized%20aluminum%20clamp%20connection%20in%20ground%20mounting%20system_-400x300w.webp)

/Aluminum%20Alloy%20Solar%20Panel%20Ground%20Mount%20Frame_-400x300w.webp)

/Adjustable%20Tilt%20Ground%20Mount%20Solar%20Racking%20System_-400x300w.webp)

/Grace%20Solar%20ground%20mount%20installation%20on%20concrete%20foundation%20with%20rail%20clamps_-400x300w.webp)

/Aluminum%20alloy%20solar%20ground%20mounting%20system%20portrait%20placement%20for%20495W%20panels_-400x300w.webp)