Table of Contents

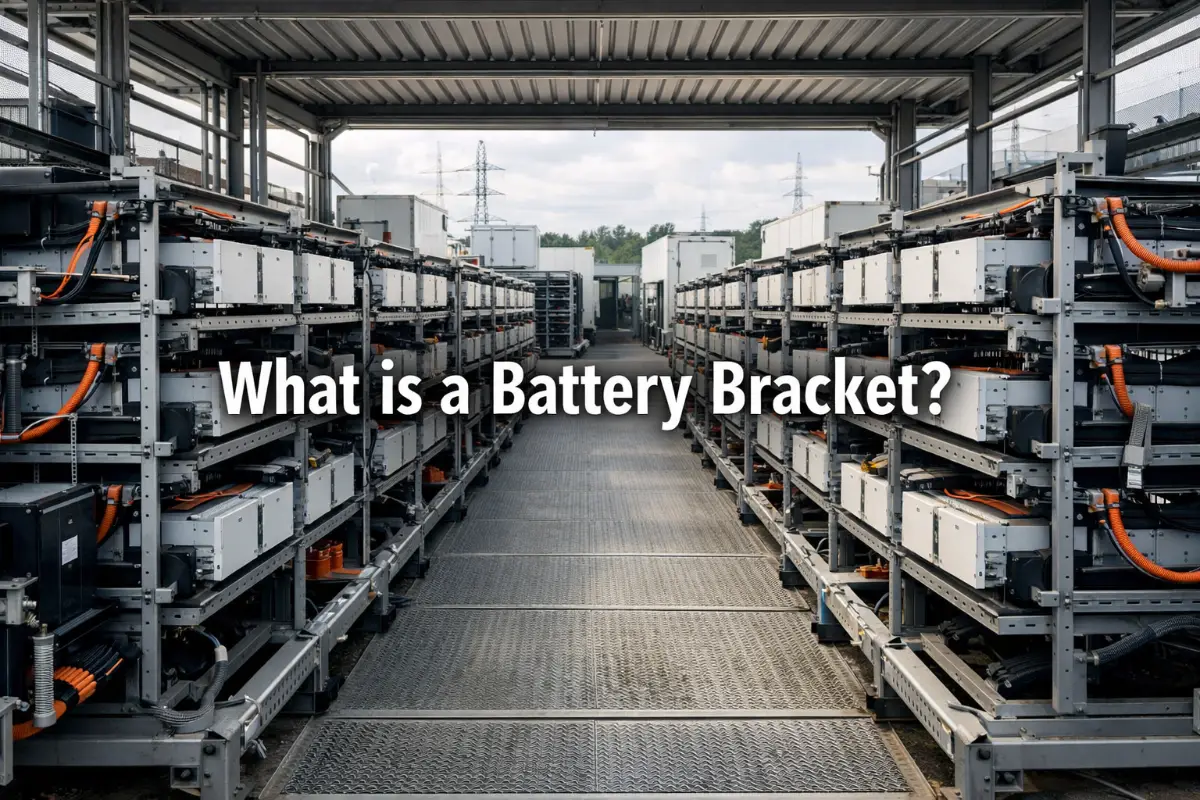

What is a Battery Bracket?

At its core, a battery bracket (often interchangeably called a battery holder, clamp, or tie-down) is a fundamental securing device. Its primary job is to immobilize a battery within a vehicle, piece of equipment, or structure. Think of it as a specialized seatbelt for your battery, preventing it from becoming a hazardous, heavy projectile due to vibration, impact, or simple gravity. While simple in concept, its execution varies dramatically from securing a small 12V battery in a fishing shelter to anchoring multi-ton energy storage containers in a solar farm.

Primary Functions of a Battery Bracket

Why is this component non-negotiable? A loose battery is a significant safety and operational risk. The key functions of a well-designed battery bracket are:

1. Safety and Security

This is the foremost role. A bracket physically restrains the battery, preventing excessive movement that could lead to:

- Internal Damage: Excessive shaking can damage the battery's internal plates, leading to premature failure.

- Terminal Damage: Movement can strain or break the cable connections at the terminals, causing electrical shorts, arcing, or complete power loss.

- Physical Hazards: In an accident or sudden stop, an unsecured battery can break free, causing injury or damaging surrounding components.

2. Vibration and Shock Absorption

Vehicles and machinery generate constant vibration. A proper bracket, often incorporating rubber pads or isolators, dampens these vibrations, isolating the battery from harmful shocks that can shorten its lifespan.

3. Structural Stability and Alignment

It ensures the battery remains level and correctly positioned, which is crucial for certain battery types (like flooded lead-acid) to prevent electrolyte leakage and for maintaining reliable terminal contact.

Common Types & Everyday Applications

Based on prevalent search results, consumer and automotive battery brackets dominate everyday queries:

• Automotive Battery Hold-Downs

The most searched-for type. These are typically J-bolt kits with a top-mounted bar or strap that clamps the battery to the tray. Materials range from coated steel for OEM replacements to corrosion-resistant aluminum or stainless steel for performance and marine applications. As noted in maintenance guides from sources like NAPA, checking this bracket's tightness is a critical, often overlooked part of vehicle upkeep.

• Recreational & Equipment Brackets

These are designed for specific niches. Examples from your search results include brackets for ice fishing shelters (like the Clam Outdoors model) to hold flasher batteries, or universal adjustable brackets from brands like Genesis Offroad for mounting auxiliary batteries in trucks, RVs, or boats. They often feature Velcro straps or adjustable arms for versatility.

• Custom & Aesthetic Brackets

In performance automotive and show car circles, battery brackets become part of the engine bay's aesthetics. Companies like Billet Specialties or ZSPEC Design offer CNC-machined, anodized aluminum brackets that provide superior hold while adding a polished, custom look.

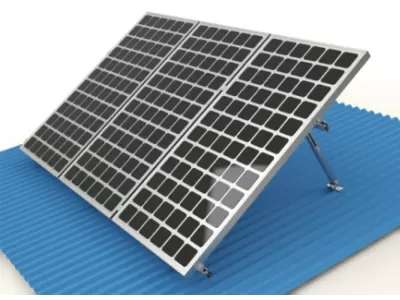

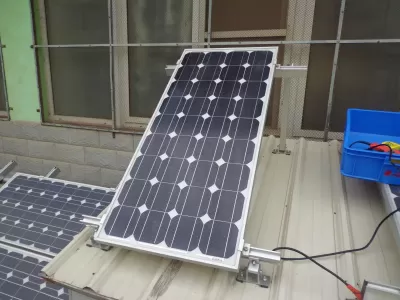

The Industrial Scale: Battery Brackets for Energy Storage

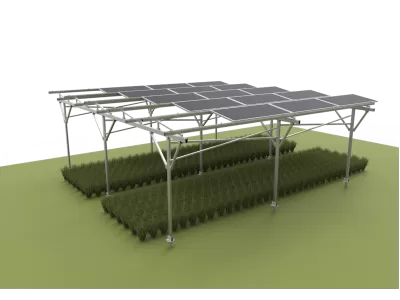

The principle of securing a power source scales up dramatically in renewable energy and industrial applications. Here, the "battery bracket" evolves into a complete energy storage mounting structure. This is where a global leader in solar mounting systems like Grace Solar applies decades of engineering expertise.

For utility-scale solar farms or commercial backup power systems, batteries are housed in large racks or containers. The supporting structure must handle immense weight, environmental forces, and provide long-term durability. Key systems include:

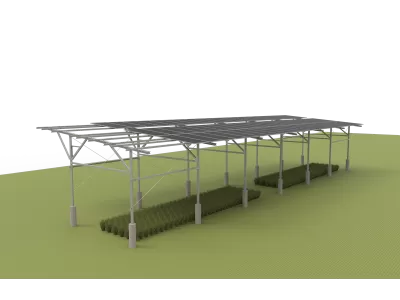

1. Ground-Mounted Energy Storage Structures

Similar to solar ground mounts, these are heavy-duty frameworks, often using high-strength H-beam steel (like Q235/Q355), designed to support rows of large battery cabinets. For instance, our G58 Energy Storage Structure is engineered for high mechanical performance, stability under heavy loads, and corrosion resistance, ensuring a secure foundation for massive battery arrays for decades.

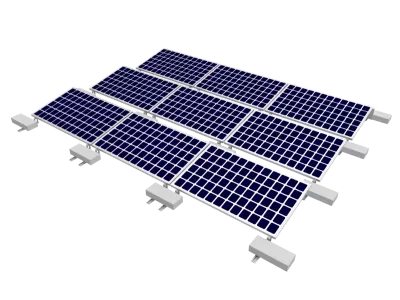

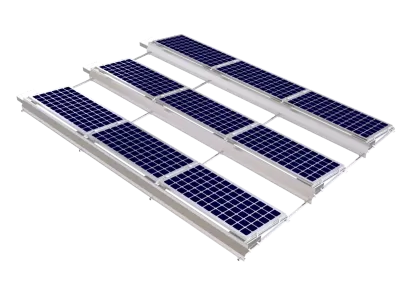

2. Containerized & Top-Mount Solutions

A highly efficient solution involves mounting solar panels directly onto energy storage containers. Our Container Top Mounting Structure uses a robust combination of H-beam and C-purlin steel. This design does more than just secure panels; it reduces solar heat radiation onto the container, enhancing internal cooling and significantly extending the lifespan of the sensitive battery equipment within.

3. Integrated Systems with Noise Barriers

In projects near residential areas, energy storage sites may require noise mitigation. Our integrated systems can combine the structural strength of a battery support framework with acoustic barrier panels, like the C5 Noise Barrier System, which offers high sound insulation and wind resistance while maintaining structural integrity—addressing multiple site requirements with one engineered solution.

From Grace Solar's Perspective

At Grace Solar, with over a decade of experience and a global installed capacity of 48GW, we view "battery bracketing" through the lens of large-scale system integration, longevity, and bankability. An industrial energy storage bracket isn't just a holder; it's a critical piece of civil and mechanical engineering that must be designed for specific wind loads (e.g., up to 46m/s), snow loads, corrosion resistance (using hot-dip galvanizing or ZM coatings), and a lifespan matching the 10+ year warranty of the batteries it supports.

We provide customized mounting solutions for energy storage projects. Whether for a ground-mounted battery bank, a container-based system, or a hybrid solar-plus-storage plant, our engineering team can develop the optimal structural solution. Contact us to discuss your specific project requirements.

Key Considerations for Selection and Design

Choosing the right bracket depends entirely on the application:

- Material & Corrosion Resistance: For automotive use, zinc-plated steel is common. For marine/off-road, stainless steel or anodized aluminum is superior. For industrial ground mounts, hot-dip galvanized structural steel is mandatory.

- Adjustability vs. Precision: Universal automotive kits offer adjustability for different battery sizes. High-performance or industrial brackets are often precision-engineered for a specific battery model or container dimension.

- Environmental Loads: Industrial designs must be certified to local wind and seismic codes (e.g., ASCE 7, Eurocode).

- Thermal Management: Large-scale storage systems must consider airflow around battery cabinets. Bracket designs should not impede necessary ventilation or cooling.

- Ease of Installation & Maintenance: Design should allow for safe battery placement, connection, and future replacement or service.

Conclusion: More Than Just a Holder

From a simple $10 J-bolt kit securing your car's battery to a multi-million-dollar, engineered structure supporting a community's backup power, the battery bracket plays a vital, unifying role: ensuring safety, stability, and performance.

For your everyday needs, ensure your vehicle's hold-down is snug and corrosion-free. For large-scale renewable energy and storage projects, partnering with an experienced engineering firm like Grace Solar ensures that the "bracket" for your energy investment is designed, built, and certified to be as reliable and durable as the batteries themselves. Explore our comprehensive Solar Solutions for more on how we engineer stability for the future of energy.