Table of Contents

- • Defining the Foundation: What is an Energy Storage Mounting System?

- • Types and Applications: Mounting Solutions for Every Scale

- • 5 Key Design & Safety Considerations for a Robust System

- • Engineered for Excellence: The Grace Solar Approach

- • Getting Started with Your Project

Defining the Foundation: What is an Energy Storage Mounting System?

An Energy Storage Mounting System is the critical, often underrated, structural framework that securely holds, supports, and integrates battery units and their related power conversion components. Far more than simple brackets or generic racks, it is a precision-engineered solution that forms the physical backbone of any Battery Energy Storage System (BESS). Its primary function is to ensure the absolute safety, long-term stability, optimal performance, and regulatory compliance of storage assets across residential, commercial & industrial (C&I), and utility-scale applications.

A professionally designed system holistically accounts for constant static loads (battery weight), dynamic forces (seismic activity, wind), environmental challenges (corrosion, temperature swings), thermal management requirements, maintenance accessibility, and stringent local/national building and electrical codes. Neglecting any of these factors can compromise the entire investment.

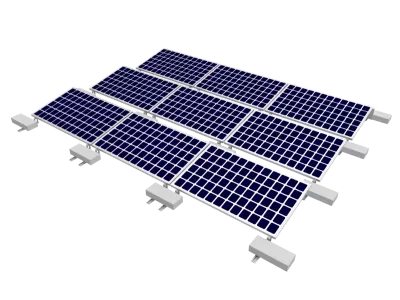

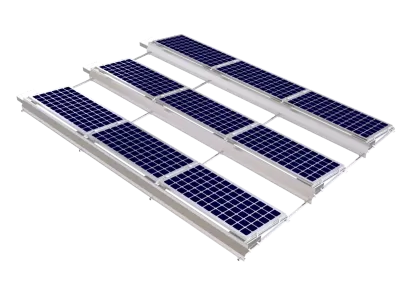

Types and Applications: Mounting Solutions for Every Scale

The design and complexity of the mounting system vary dramatically based on the project's scale, location, and battery technology. Selecting the correct type is the first critical step in project planning.

1. Residential & Light Commercial Wall/Floor Mounts

Designed for aesthetics and space efficiency, these systems secure standalone units like the Tesla Powerwall, LG Chem RESU, or VARTA.wall. Typical installations are in garages, utility rooms, or on exterior walls.

- Key Features: Low-profile, powder-coated finishes for corrosion resistance, pre-drilled mounting patterns for quick installation, and often included cable management channels.

- Installation Focus: Identifying structurally sound wall studs or preparing a level concrete pad, ensuring mandated clearance distances for ventilation and safety, and achieving a clean, integrated look with the home's electrical system.

- Standards: Must comply with residential building codes and specific manufacturer installation guides to maintain warranty validity.

2. Commercial & Industrial (C&I) Modular Racks and Enclosures

For backup power, peak shaving, or demand-charge management in businesses, modular rack systems are the standard. They house multiple battery modules (e.g., from Pylontech, Dyness) in a scalable, server-rack style format.

- Key Features: Heavy-duty steel construction, standardized 19-inch or custom widths, scalable stacking with interlocking brackets, integrated blind-mate electrical connectors, and built-in cable trays.

- Design Focus: Floor load capacity analysis, aisle spacing for serviceability (NEC Article 110 requirements), seismic bracing for high racks, and integration with facility-level HVAC and fire suppression systems.

- Standards: Often require UL 9540 certification for the entire energy storage unit and must meet more rigorous IBC (International Building Code) and NFPA (National Fire Protection Association) standards for commercial spaces.

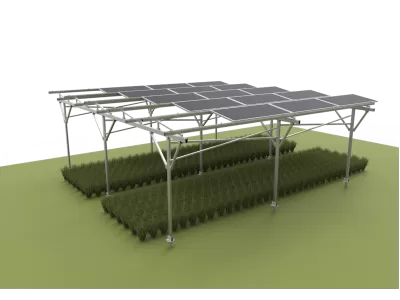

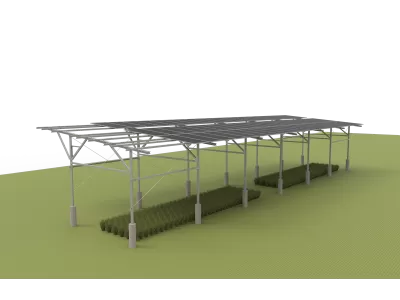

3. Utility-Scale Containerized and Custom Ground-Mount Systems

At the megawatt scale, batteries are pre-assembled within 20- or 40-foot shipping containers (like solutions from Jinko ESS or Fluence) or installed in custom-built shelters. The mounting system here is two-tiered.

- Internal Racking: Custom-engineered steel frames that hold thousands of individual battery cells or modules. They must facilitate forced air or liquid cooling pathways, allow for cell-level monitoring access, and be designed for easy module replacement.

- External Foundation & Site Work: This is a major civil engineering task. It involves designing reinforced concrete foundations, anchor bolt layouts, and potential pilings to support multiple 30+ ton containers. The design must account for extreme wind loads, seismic zone factors (ASCE 7), snow loads, and potential flood elevation (FEMA zones). Proper spacing between containers for fire safety and maintenance access is paramount.

5 Key Design & Safety Considerations for a Robust System

A safe and reliable mounting solution is the product of meticulous engineering that addresses these five core areas.

1. Structural Integrity & Dynamic Load Analysis

The system must be designed with significant safety factors beyond the total dead load. Professional engineering analysis using software like RISA or SAP2000 is essential to model forces from:

- Seismic Forces: Calculating the correct response spectrum and anchor bolt shear/ tension loads per IBC and ASCE 7 standards, especially in high seismic zones like the Pacific Rim.

- Wind Uplift: For outdoor and containerized systems, preventing overturning is critical.

- Transportation & Handling: The internal racking must survive the forces of shipping and crane lifts during installation.

2. Corrosion Protection & Material Science

The choice of material directly impacts system lifespan, particularly in harsh environments.

- Hot-Dip Galvanized Steel (HDG): The industry benchmark for outdoor and industrial applications, providing decades of protection. The coating thickness (e.g., G90) should be specified.

- Aluminum Alloys: Excellent for coastal (salt spray) environments due to inherent corrosion resistance and lighter weight, though often at a higher cost.

- Powder Coating: Applied over galvanized steel for additional protection and aesthetic color matching, typically specified with a minimum thickness (e.g., 80 microns).

3. Thermal Management Integration

Batteries generate heat during operation. The mounting system must not become a thermal barrier.

- Airflow Optimization: Designs must incorporate specific plenum spaces, ventilation slots, or open channel layouts as dictated by the battery manufacturer's thermal management requirements.

- Liquid Cooling Interface: For high-density systems, the racking may need to incorporate mounting points and routing for cold plates or coolant manifolds.

- Material Thermal Properties: The thermal conductivity and expansion coefficients of the mounting materials are considered to avoid stress points.

4. Accessibility, Serviceability & Future Expansion

A good design facilitates the entire lifecycle of the system.

- Modular Design: Allows for the addition of battery modules in the future without replacing the entire rack structure.

- Tool Clearance & Safe Working Zones: Ensuring technicians have safe access to every connection point, communication port, and safety disconnect with appropriate tools.

- Component Labeling & Cable Routing: Integrated lugs and clearly defined paths for power and communication cables prevent errors and ensure a clean, maintainable installation.

5. Compliance, Certification & Local Authority Having Jurisdiction (AHJ) Approval

Navigating the regulatory landscape is non-negotiable. The mounting system must be part of a compliant overall installation.

- Product Certifications: Seeking components with relevant marks (UL, TÜV, CE) provides a baseline of tested safety.

- System-Level Certification: For larger installations, the entire BESS, including its mounting and enclosure, may require certification to standards like UL 9540.

- Permitting Package Support: A professional provider should supply stamped engineering drawings (structural, electrical, site plans), load calculations, and material spec sheets necessary for AHJ permit approval.

- Fire Codes & Setbacks: The design must adhere to fire code mandated setbacks from property lines, buildings, and other containers, which directly influence the site plan and foundation design.

Engineered for Excellence: The Grace Solar Approach to Energy Storage Mounting

The transition to integrated solar-plus-storage projects demands a provider with expertise in both domains. Grace Solar brings over a decade of proven engineering leadership in global solar mounting to the forefront of energy storage infrastructure. With a cumulative 48GW of solar mounting installed worldwide and a deep understanding of structural dynamics in diverse environments, our venture into custom Energy Storage Mounting Systems is a strategic evolution of our core mission: to deliver secure, reliable, and innovative structural solutions for the global energy transition.

We move beyond off-the-shelf products to offer consultative, custom-engineered solutions. Our process involves:

- Collaborative Design: Our in-house engineering team works directly with your project planners, battery suppliers, and EPC contractors to develop layouts and specifications that optimize space, cost, and performance.

- Advanced Simulation & Testing: Leveraging our fully-equipped laboratory and advanced design software, we perform finite element analysis (FEA) on rack designs and validate prototypes, ensuring they meet or exceed all calculated load requirements.

- Seamless Integration Focus: We design with the bigger picture in mind, ensuring our storage mounting solutions interface cleanly with our own solar mounting systems for co-located projects, creating a unified and dependable renewable energy asset.

- Global Compliance Support: Backed by our extensive portfolio of international certifications (UL, TUV, CE, JIS, etc.), we provide the comprehensive documentation packages needed to streamline local permitting and approval processes for your storage project, anywhere in the world.

Getting Started with Your Project

The foundation of a successful energy storage project is laid during the planning phase. Partnering with an experienced mounting system engineer early can prevent costly delays, redesigns, and compliance issues down the line.

Whether you are an installer deploying a single residential unit, a business planning a commercial peak-shaving system, or an EPC contractor engineering a multi-megawatt grid storage facility, Grace Solar's technical team is equipped to support you.

Ready to secure your energy storage investment with a professionally engineered mounting solution?

Contact Grace Solar today to initiate a consultation. Share your battery specifications, project site details, and capacity goals. Our experts will collaborate with you to develop a safe, compliant, and optimized Energy Storage Mounting System engineered for performance and longevity.