Table of Contents

- What is Concentrated Solar Power (CSP)?

- Core CSP Technologies: Parabolic Trough, Power Tower & More

- The Global CSP Landscape: Key Markets & Pioneering Projects

- Critical Engineering Challenges in CSP Plant Construction

- Grace Solar's Expertise: Precision Solutions for CSP Projects

- The Future of CSP: Dispatchable Power for a Sustainable Grid

- Frequently Asked Questions (FAQ) About CSP

What is Concentrated Solar Power (CSP)?

In the quest for reliable, clean energy, Concentrated Solar Power (CSP) stands out as a unique and powerful technology. Unlike photovoltaic (PV) panels that convert sunlight directly into electricity, CSP plants use thousands of mirrors to concentrate sunlight onto a receiver, generating intense heat. This thermal energy, often at temperatures exceeding 400°C, is then used to drive conventional steam turbines or engines to produce electricity.

The defining advantage of CSP is its seamless integration with thermal energy storage (TES), typically using molten salts. This allows CSP plants to store solar energy as heat for several hours and generate electricity on demand—even after sunset or during peak demand periods. This dispatchability makes CSP a invaluable asset for grid stability, complementing intermittent renewables like PV and wind. With over 6.8 gigawatts (GW) of capacity operational globally and pioneering hybrid projects scaling up, CSP is proving its role in the future energy mix.

Core CSP Technologies: Parabolic Trough, Power Tower & More

CSP plants are categorized by their mirror configuration and receiver design, each with distinct advantages.

1. Parabolic Trough Systems

The most commercially proven technology, parabolic troughs use long, curved mirrors to focus sunlight onto a receiver tube running along the mirror's focal line. A heat transfer fluid inside the tube is heated to around 400°C and used to generate steam. Their linear design and single-axis tracking make them suitable for large-scale deployment in arid regions.

2. Solar Power Tower (Central Receiver)

Power tower systems use a field of sun-tracking mirrors (heliostats) to concentrate sunlight onto a central receiver atop a tall tower. This allows for much higher operating temperatures (often above 560°C), leading to greater thermodynamic efficiency and more cost-effective thermal storage. They are the technology of choice for the latest generation of large-scale CSP projects.

3. Linear Fresnel Reflectors (LFR)

LFR systems use rows of flat or slightly curved mirrors close to the ground to reflect light onto a fixed, elevated receiver. While potentially lower in cost and land use, they generally operate at lower temperatures and have seen less widespread commercial adoption than trough and tower systems.

4. Dish/Engine Systems

These are modular units comprising a parabolic dish that concentrates light onto a receiver at its focal point, linked to a Stirling or Brayton engine. They offer high efficiency and are ideal for decentralized, off-grid applications but are not typically used for utility-scale power generation.

The Global CSP Landscape: Key Markets & Pioneering Projects

Global CSP deployment, tracked by entities like SolarPACES and the National Renewable Energy Laboratory (NREL), shows concentrated growth in sunbelt regions with strong policy support and high Direct Normal Irradiance (DNI).

- Spain & the United States were the early pioneers and still hold the largest installed capacity, home to iconic projects like the SEGS plants and Ivanpah.

- North Africa & the Middle East are now the epicenter of innovation. Morocco's Noor Ouarzazate complex and the UAE's Noor Energy 1 in Dubai (the world's largest single-site CSP project at 950MW, combining tower, trough, and PV) set new benchmarks for scale and storage.

- China has rapidly become a major player, commissioning multiple 100+ MW power tower projects with advanced molten salt storage as part of its renewable energy drive.

- South Africa, Chile, and Israel also host significant CSP facilities, demonstrating the technology's adaptability.

The market trend is decisively moving towards plants with integrated storage (6-15 hours is now standard) and hybrid "CSP+PV" configurations. This hybrid model leverages PV for low-cost daytime energy and CSP's stored heat for evening peak shaving, offering an optimal solution for 24/7 renewable baseload power.

Critical Engineering Challenges in CSP Plant Construction

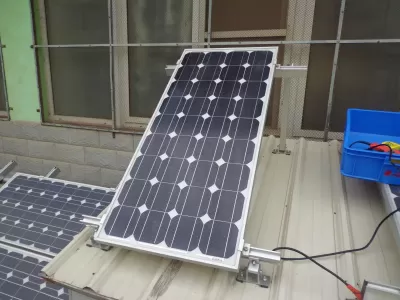

Building a CSP plant is a monumental engineering feat that goes far beyond the mirrors and turbines. The solar field's structural foundation is paramount to long-term performance and return on investment.

Structural Integrity in Extreme Environments

CSP plants are built in deserts and high-DNI regions prone to extreme winds, sandstorms, thermal cycling, and corrosion. The mounting structures for troughs or heliostats must maintain precise alignment and rigidity over a 25-30 year lifespan despite these harsh conditions. Any deformation leads to optical losses and reduced energy yield.

Precision at Scale and Timeline Control

A single project may require the installation of tens of thousands of mirror supports and trackers. The precision required for optical accuracy must be achieved at this massive scale. Efficient logistics, modular design, and flawless on-site execution are critical to control costs and meet strict commissioning deadlines.

Technology-Specific Design Demands

- For Parabolic Troughs: Requires high-torsional stiffness torque tubes and robust drive systems for perfectly synchronized single-axis tracking across kilometers of collector rows.

- For Power Tower Heliostats: Demands highly stable, individual foundations and support structures for thousands of heliostats, ensuring each mirror maintains sub-milliradian pointing accuracy to the tower receiver.

Grace Solar's Expertise: Precision Solutions for CSP Projects

At Grace Solar, we understand that the success of a CSP plant is built from the ground up. Leveraging our position as a global leader in smart solar mounting systems with a cumulative installed capacity of 48GW, we apply our engineering excellence to the unique demands of CSP.

Our mission is to "mount every solar plant firm as rock," and this principle is even more critical for the precision-dependent CSP field.

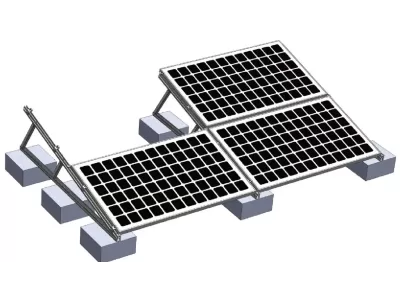

Tailored Engineering for CSP Structures

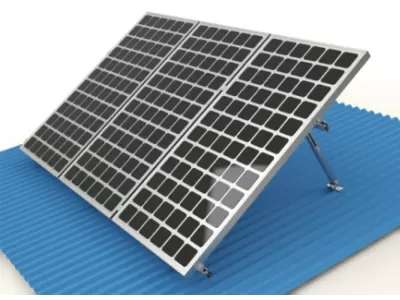

Our team of sophisticated engineers designs solutions that start with comprehensive site analysis. We utilize advanced wind tunnel testing data and finite element analysis (FEA) to create structures that withstand site-specific environmental loads. Our designs comply with international standards (AS/NZS, Eurocode, etc.) and focus on longevity through specialized anti-corrosion coatings and material selection.

From Design to Deployment: A Streamlined Process

We offer an integrated service package for CSP solar field structures:

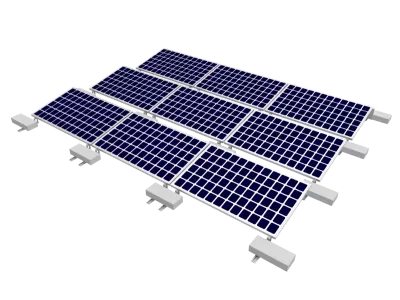

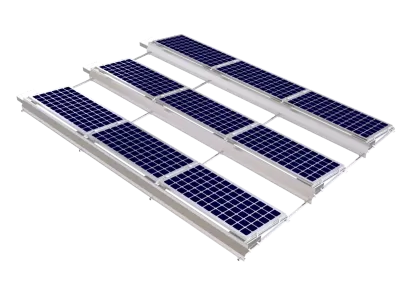

- Custom Design & Simulation: Creating optimized structural solutions for parabolic trough torque tubes, heliostat supports, or Linear Fresnel bases.

- Precision Manufacturing & Quality Control: Our 110,000 m² factory, equipped with a 2,000 m² R&D center, ensures high-volume production with meticulous "do it right the first time" quality checks.

- Logistics & On-Site Technical Support: We ensure timely delivery and provide expert supervision to facilitate efficient, accurate installation, safeguarding project timelines.

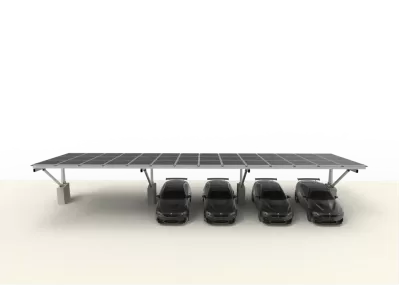

Hybrid Plant Expertise

With deep experience in both utility-scale PV tracking (GS-Light tracker) and fixed-tilt systems, Grace Solar is uniquely positioned to support the growing market of CSP-PV hybrid plants. We can provide cohesive structural planning that optimizes land use, minimizes shading, and streamlines installation for these complex, multi-technology facilities.

We invite project developers, EPC contractors, and investors to contact us to discuss custom solar mounting and structural solutions for your next-generation CSP or hybrid project. Explore our full range of capabilities on our Solar Solutions page.

The Future of CSP: Dispatchable Power for a Sustainable Grid

The future of CSP is intrinsically linked to the global need for dispatchable, carbon-free power. As grid infrastructures worldwide grapple with high penetrations of variable renewables, the value of CSP with long-duration storage is set to increase.

Research continues into next-generation "Gen 3" technologies using solid particles or supercritical CO2 as heat transfer media, aiming for higher efficiencies and lower costs. However, the immediate path forward is the strategic deployment of proven tower and trough technology with storage in high-DNI regions, and its intelligent hybridization with PV.

For this future to be realized, the industry requires not just technological innovation, but also unwavering reliability in project execution and component quality. The mirrors, receivers, and turbines represent the heart of a CSP plant, but it is the robust, precision-engineered structure that forms its steadfast backbone, ensuring decades of optimal performance.

Frequently Asked Questions (FAQ) About CSP

1. What is the main advantage of CSP over solar PV?

CSP's key advantage is its inherent ability to integrate cost-effective thermal energy storage, allowing it to generate electricity on demand, day or night. This makes it a dispatchable or "firm" renewable resource, whereas PV generation is inherently intermittent without separate (and currently more expensive) battery storage.

2. What are the key site requirements for a CSP plant?

- High Direct Normal Irradiance (DNI): Typically > 2000 kWh/m²/year.

- Large, flat land area: Approximately 5-10 acres per MW of capacity.

- Access to water (for condenser cooling) or the use of dry-cooling technology.

- Proximity to high-voltage transmission lines.

3. Why is the structure so important for a CSP plant's performance?

The entire optical efficiency of the plant depends on the precise alignment of thousands of mirrors. Structures must maintain this alignment against wind, gravity, and thermal effects over decades. A deformation of even a few millimeters can cause significant focus loss, directly reducing the plant's energy output and revenue.

4. How can Grace Solar contribute to a CSP project's success?

As a specialist in large-scale solar mounting systems, Grace Solar provides the critical structural engineering and supply for the solar field. We deliver custom-designed, high-precision support and tracking structures that ensure optical accuracy, durability in harsh environments, and efficient installation—directly impacting the project's bankability, timeline, and long-term energy yield.

/Al-Zn-Mg%20coated%20piling%20structure%20for%20extreme%20weather%20resistance_-400x300w.webp)

/Double-column%20carbon%20steel%20solar%20ground%20mount%20system%20with%20portrait%20panel%20arrang_-400x300w.webp)

/Aluminum%20alloy%20solar%20ground%20mounting%20system%20on%20sloped%20terrain_-400x300w.webp)

/Single-column%20piling%20foundation%20for%20landscape-friendly%20solar%20installation_-400x300w.webp)