Sunflower Solar Tracker delivers intelligent dual-axis precision with industry-leading terrain adaptability. Engineered for 20% north-south slopes and unlimited east-west gradients, our multi-drive system (3-5 motors per tracker) increases structural rigidity by 20% while resisting 47m/s typhoon-force winds. AI-powered algorithms switch between astronomical tracking and real-time weather adjustment, boosting energy yield by 8% for bifacial modules. With wireless control and <0.04kWh/day power consumption, it minimizes LCOE across complex PV projects.

Features

Application

Technical Specs

Features

Mechanical Aspect

Number of Tracker Drive Modules | 2X60 | Material | Hot-dip Galvanized Steel + Aluminum-Magnesium-Zinc Plate + Pre-Galvanized |

Number of Motors Per Tracker | 1 | East-west Land Slope | <5% |

Tracking Range | ±60° | Module Arrangement | Single Row Vertical, 2 Rows Linkage |

North-south Land Slope | <15° | Foundation Form | Static Pressure Pile, Cement Precast Pile, Concrete Foundation |

Mechanical Tracking Accuracy | ±2° | Standard Wind Speed | <47m/s,3Seconds Gust (Customizable) |

Protection Wind Speed | 18m/s | Ground Clearance | >500mm (Customizable) |

Land Occupation Rate | 0.3 | Grounding Method | Self-Grounding |

Electrical Aspect

Drive Way | Rotary Drive | Motor Protection | Overheat Protection, Overcurrent Protection, Self-locking Protection |

Motor Power | 150W | Limit Protection | Mechanical Limit + Motor Hard Limit + Soft Limit |

Flat Time | <8 Minutes | Control Mode | Independent GPS Time Control + Tilt Sensor Hybrid Control |

Controller | MCU | Power Consumption | < 0.1kWh/Day |

Control Tracking Accuracy | <2° | Power Supply | String Power Supply / External Power Supply |

Protection Level | IP65 | Communication Method | RS485 Modbus Agreement |

Operating Temperature | -40-+70℃ | Signal Transmission Method | Wired / Wireless Optional |

_-800x600h.webp)

-800x600h.webp)

-800x600h.webp)

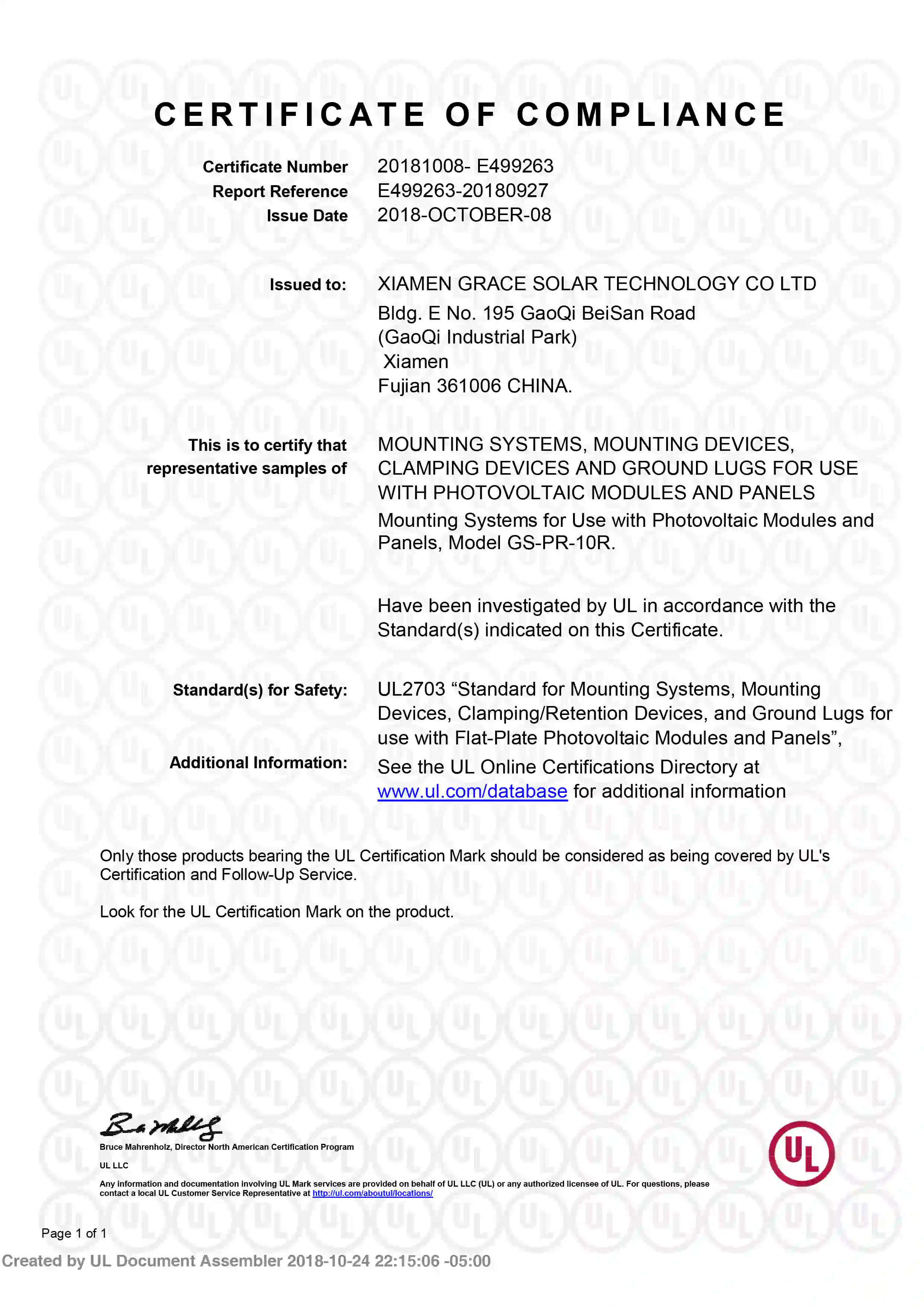

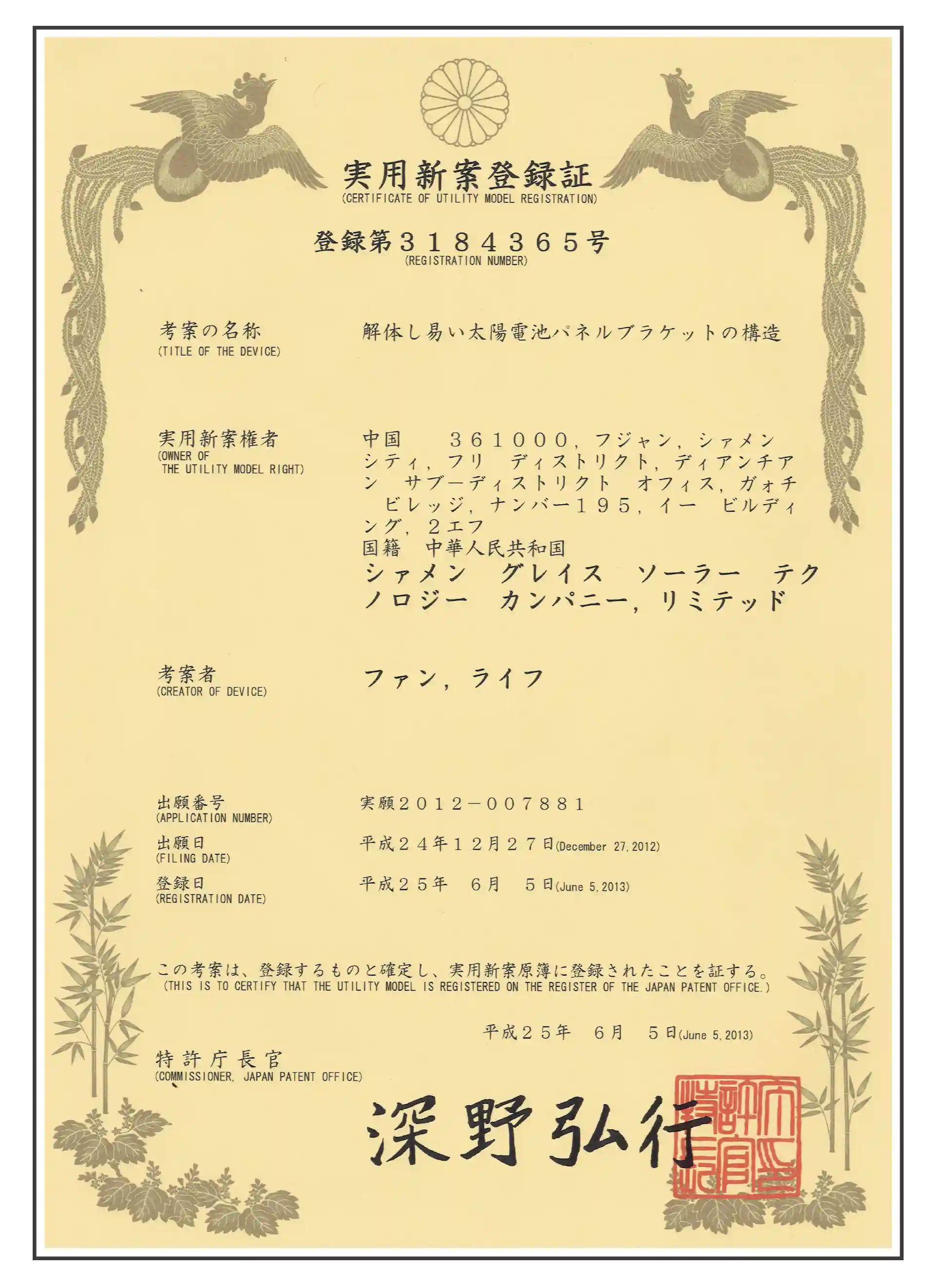

_-2480x3507.webp)

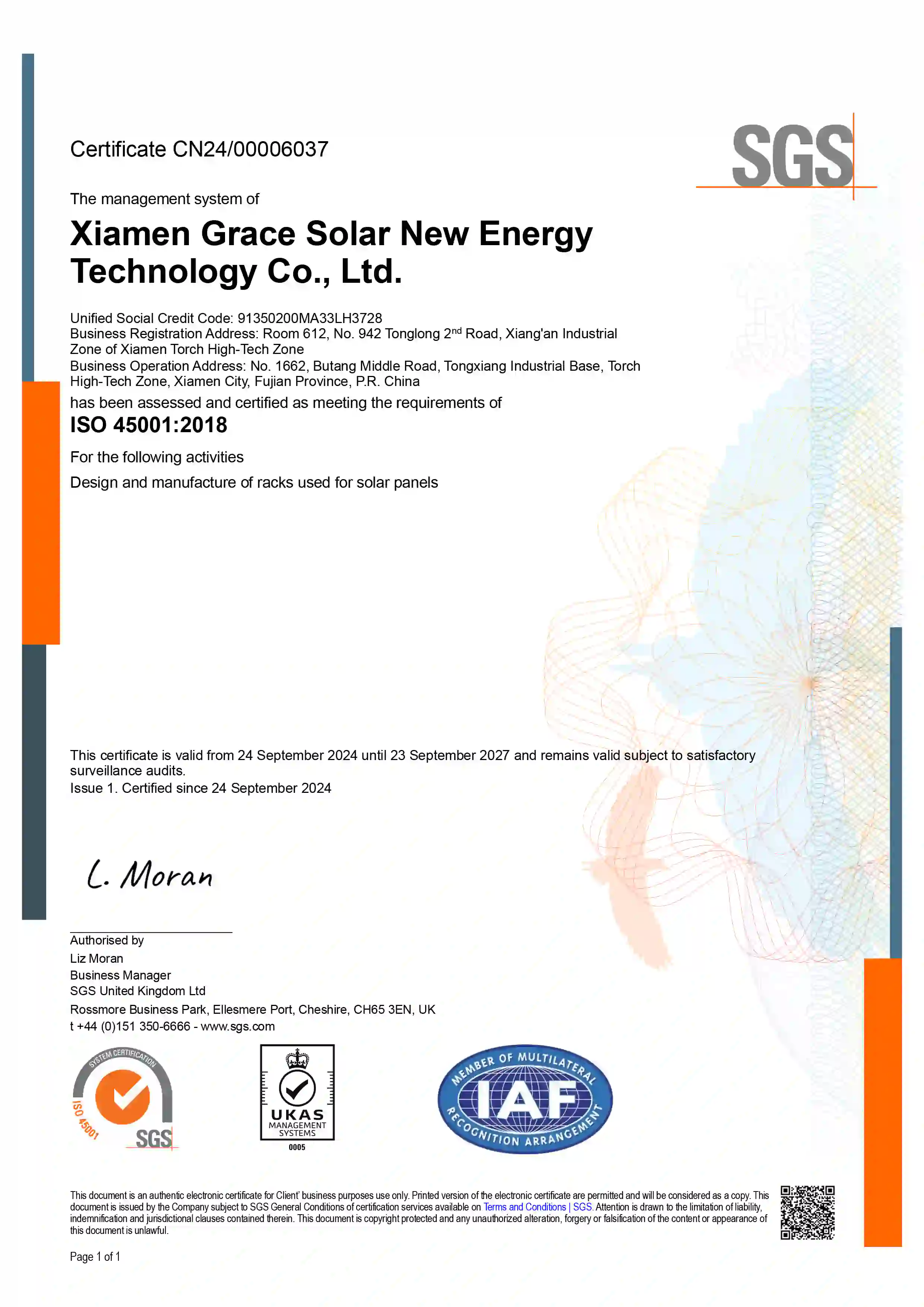

__1-1900x2643.webp)

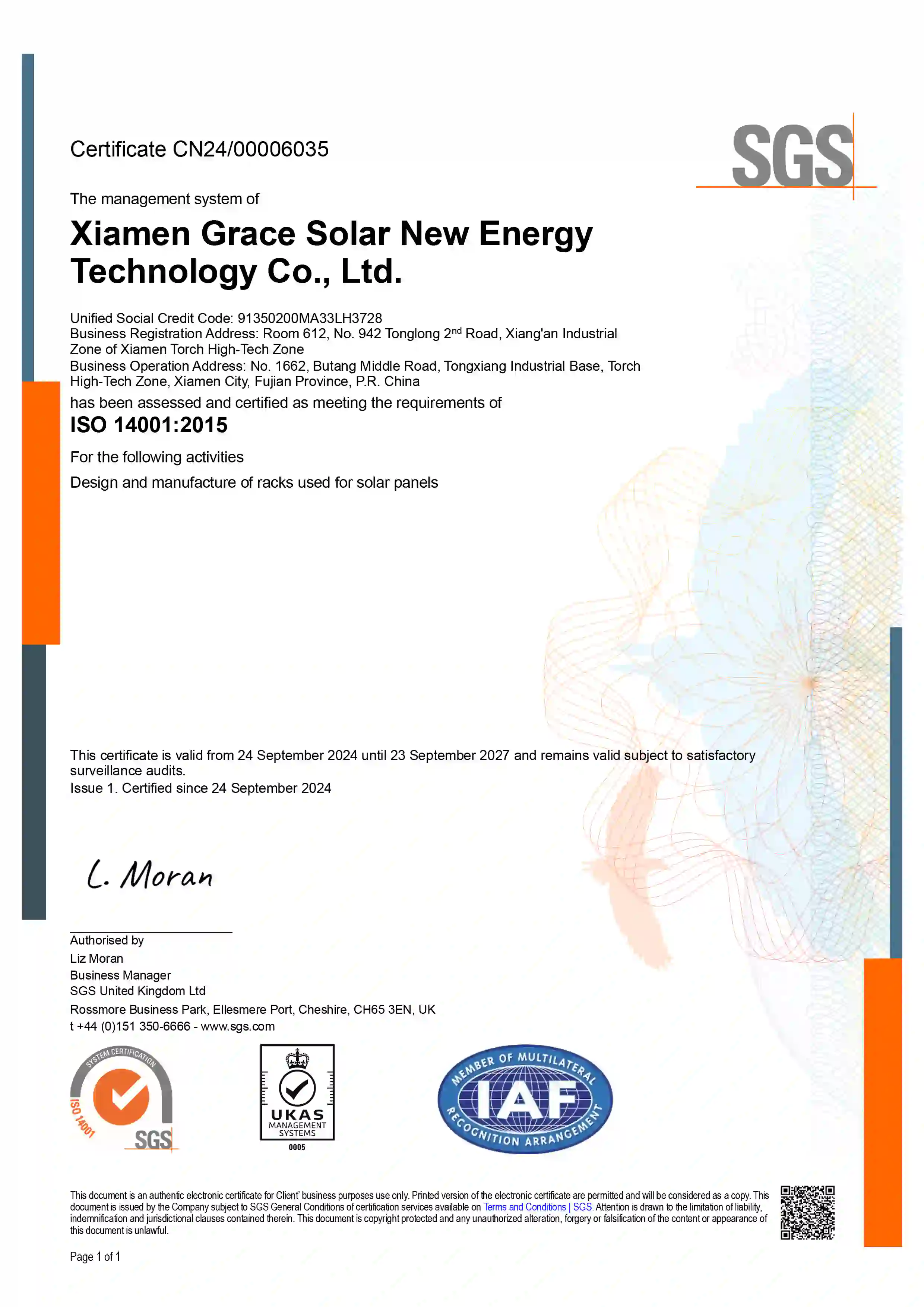

_-2480x3507.webp)

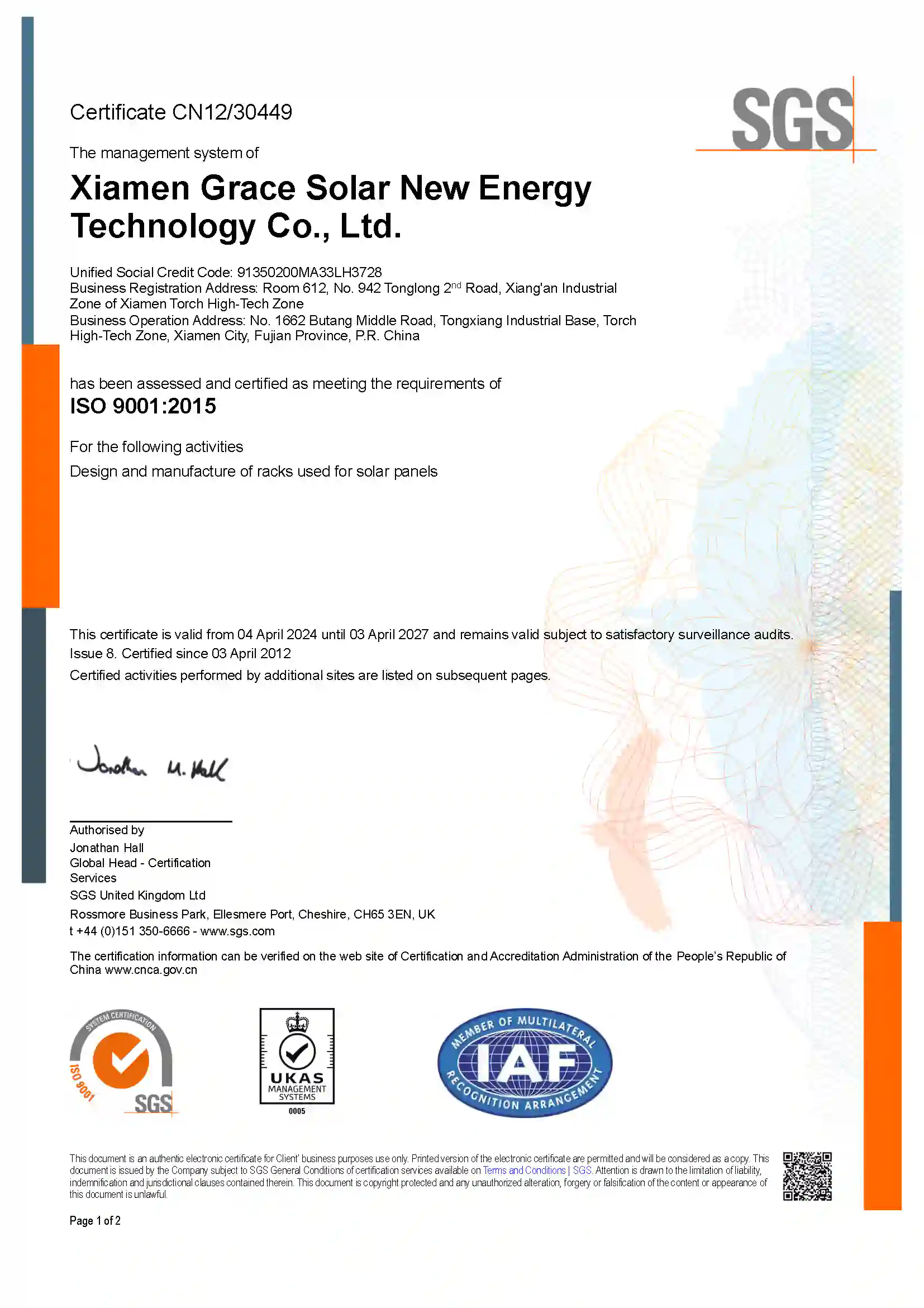

_-2480x3507.webp)