Features

Dual-column aluminum ground mounting system for high-efficiency solar farms. Resists 60m/s winds, 200cm snow loads, and 30-year corrosion. Pre-assembled for fast installation with global certifications.

Application

It Is Suitable For Various Power Plant Projects, Especially In Power Plant Projects With Irregular Land.

Technical Specs

Global Client Testimonials

Real Feedback from 100+ Countries

Project Portfolio

15-year expertise | Serving 100+ countries | 48GW+ installed globally. From deserts to polar zones, we deliver AI-driven trackers, ground/roof/carport/farm solutions, powering Fortune 500 partners with TUV/JIS/CE-certified tech.

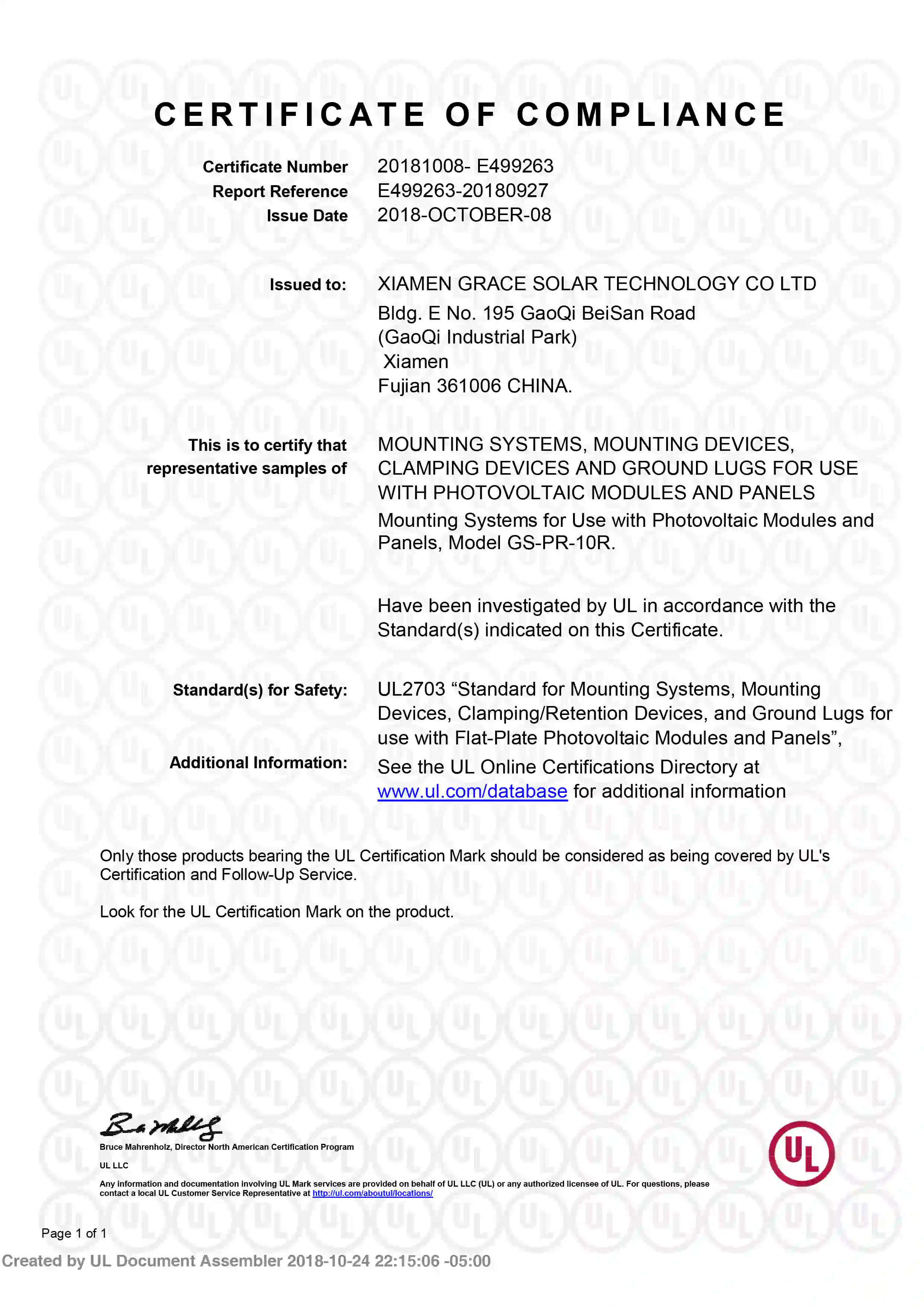

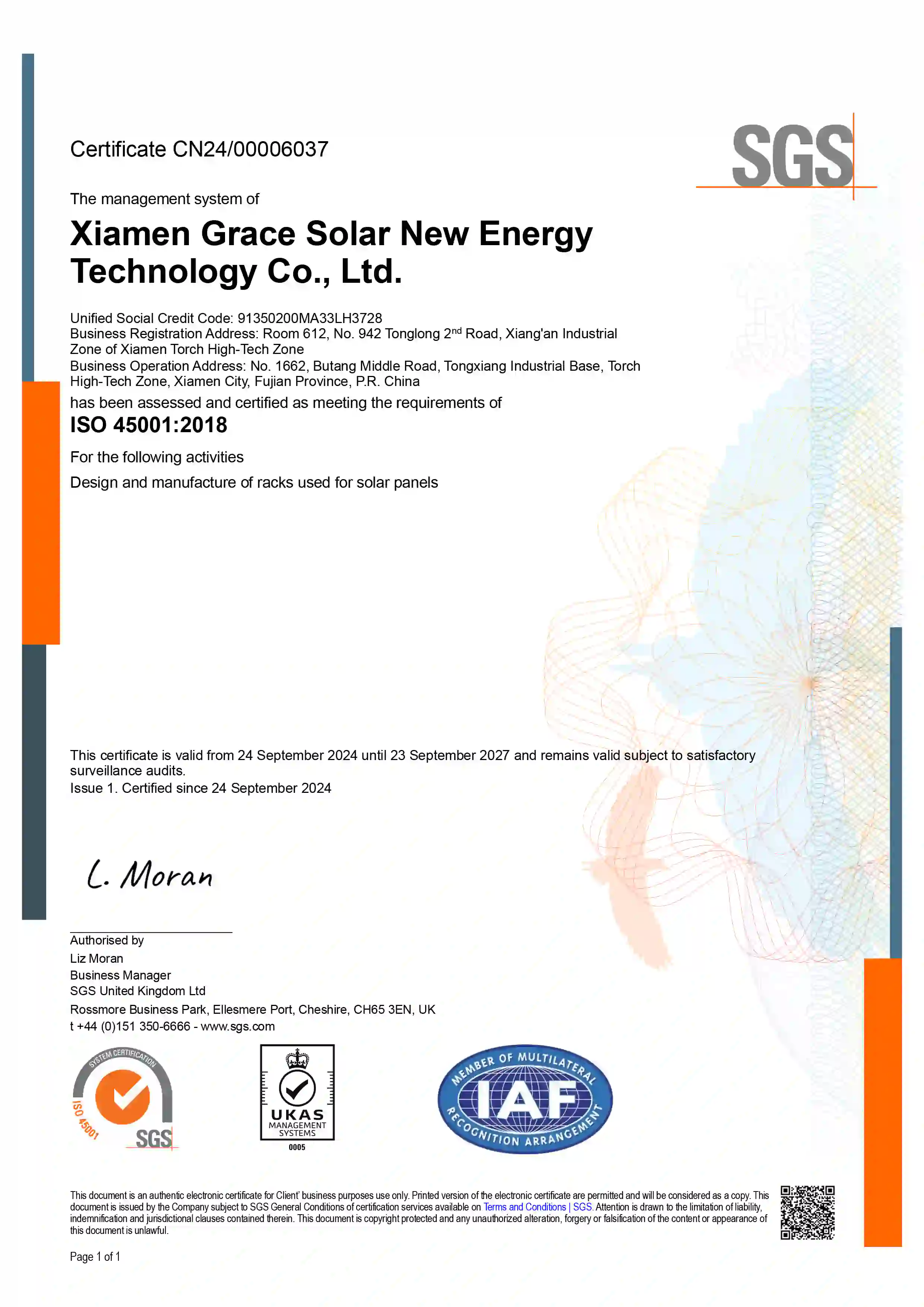

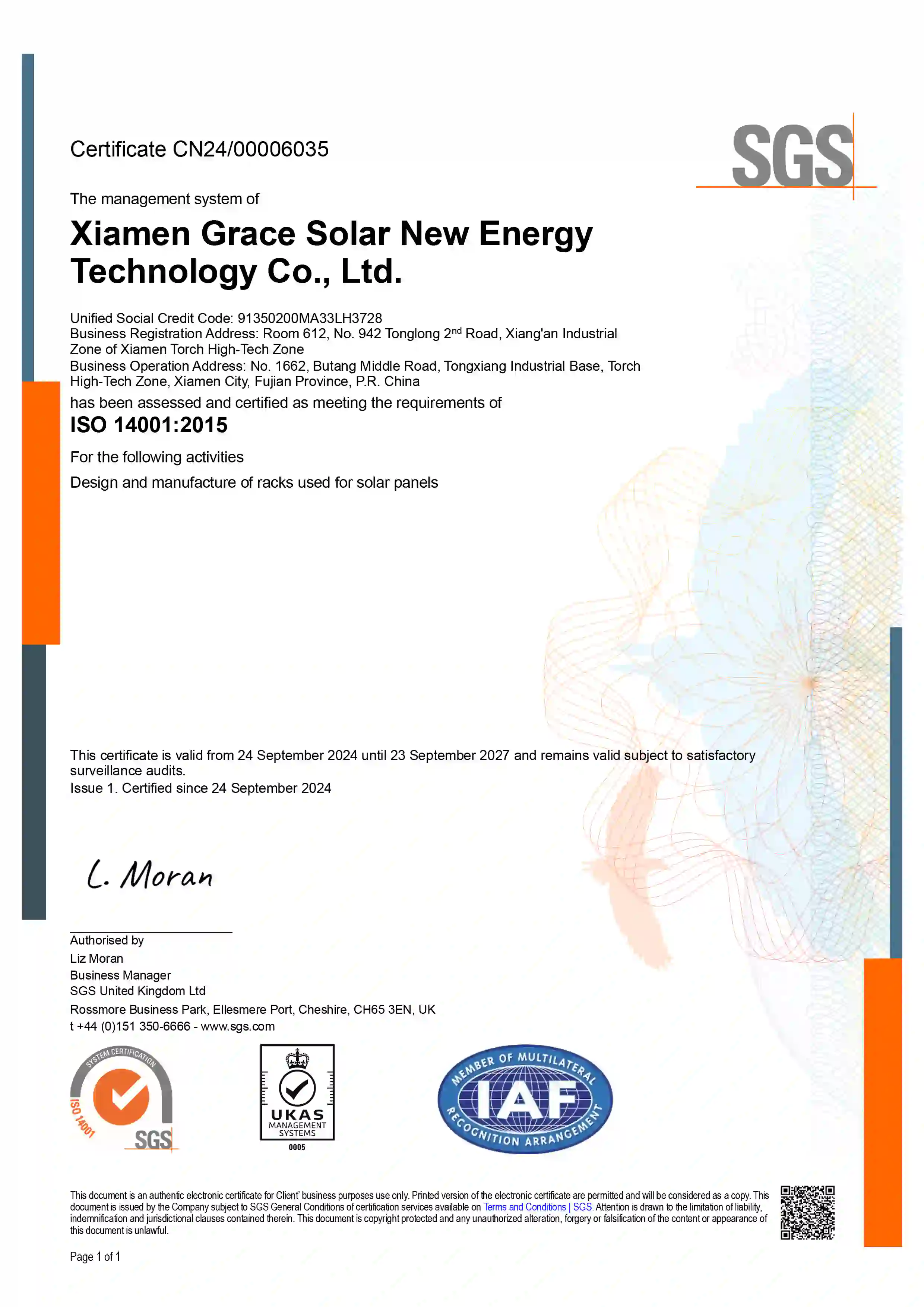

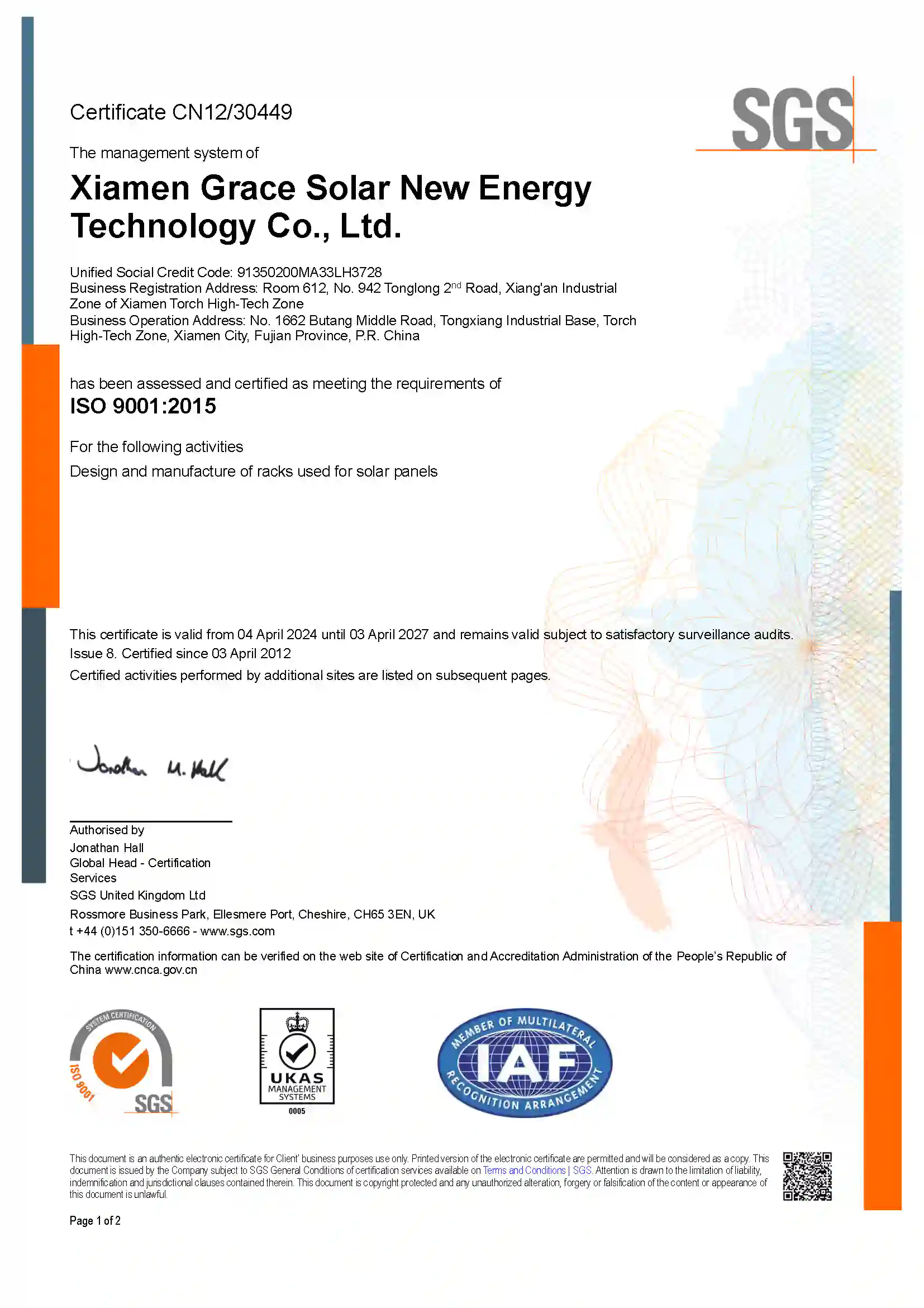

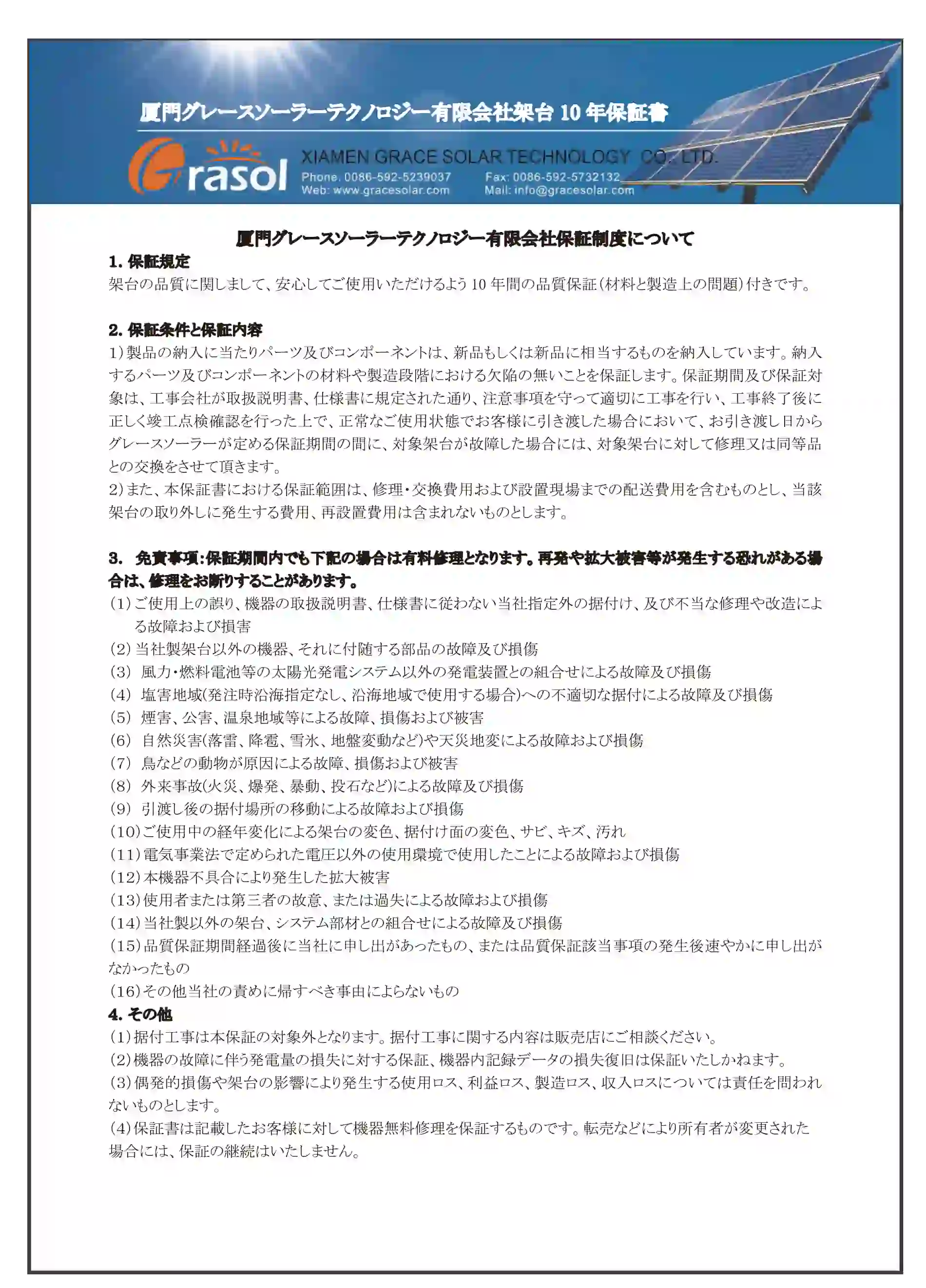

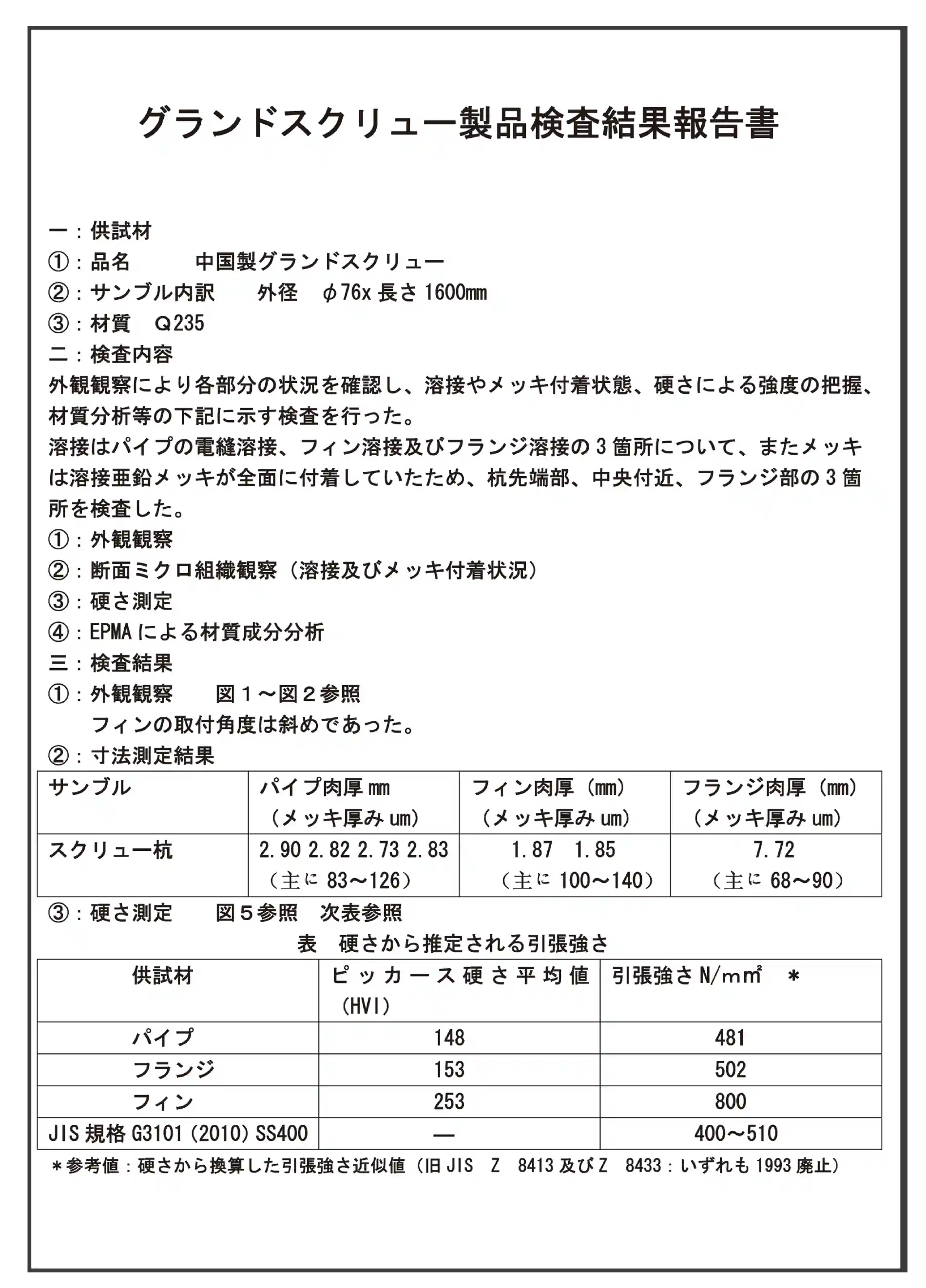

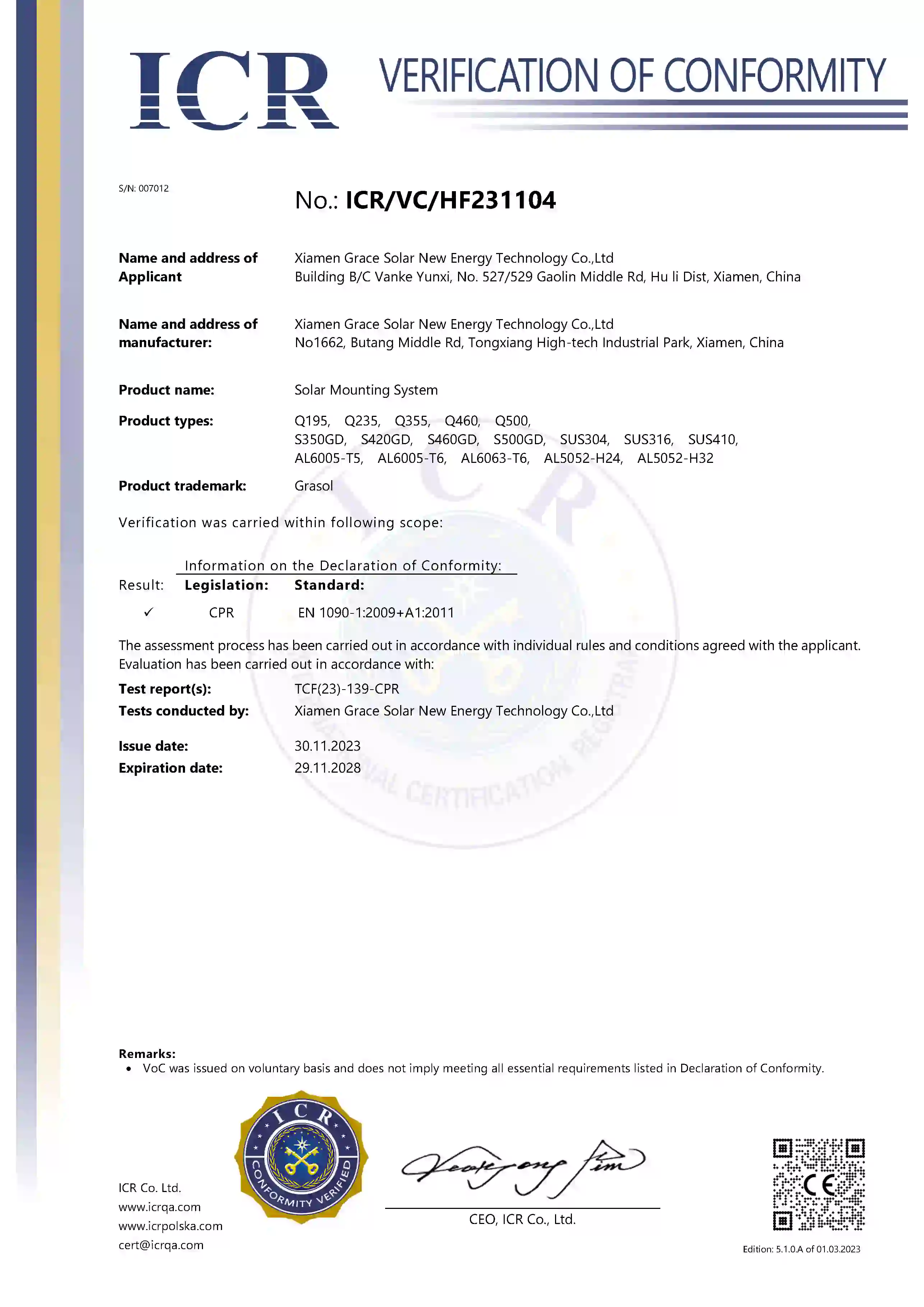

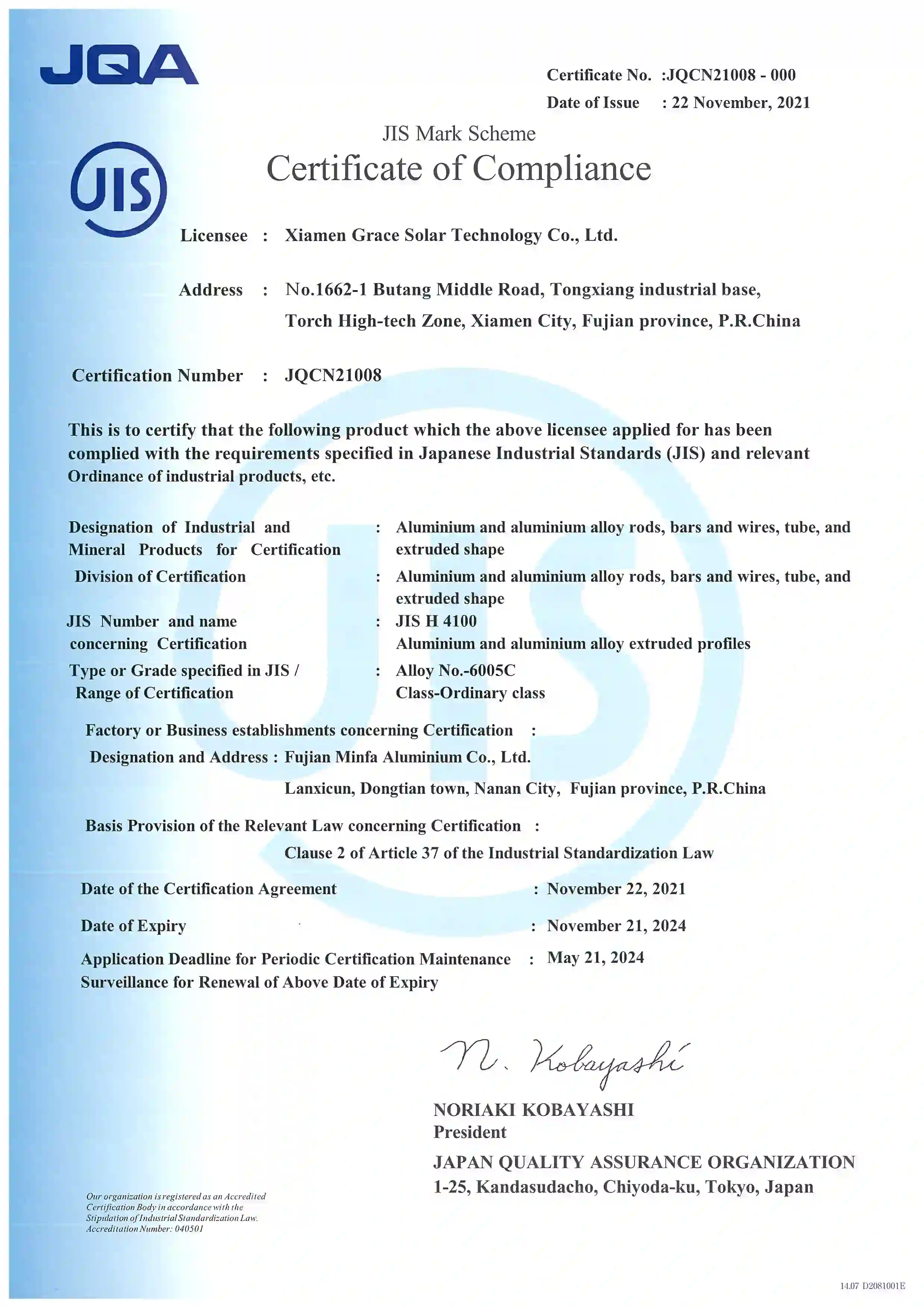

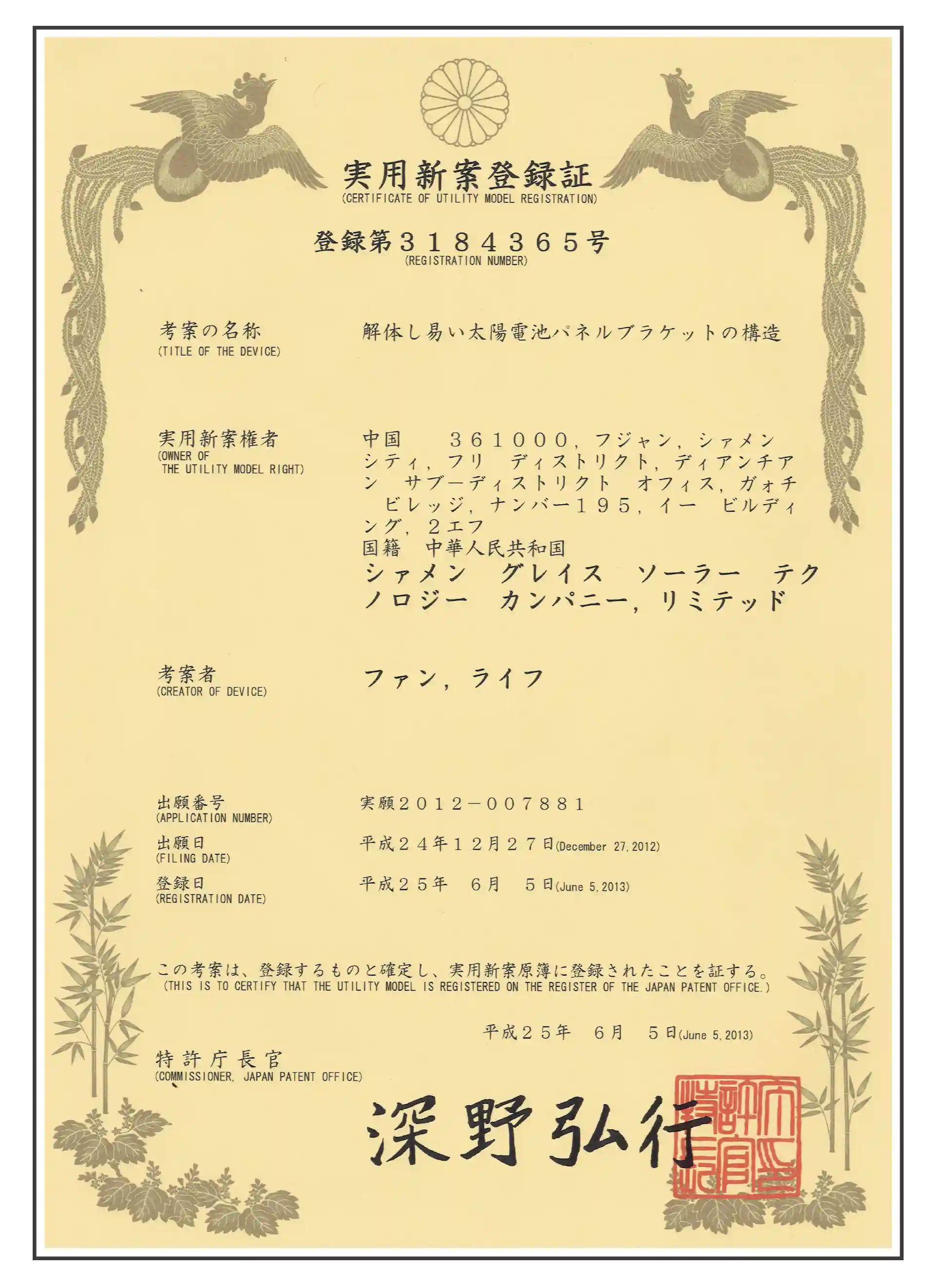

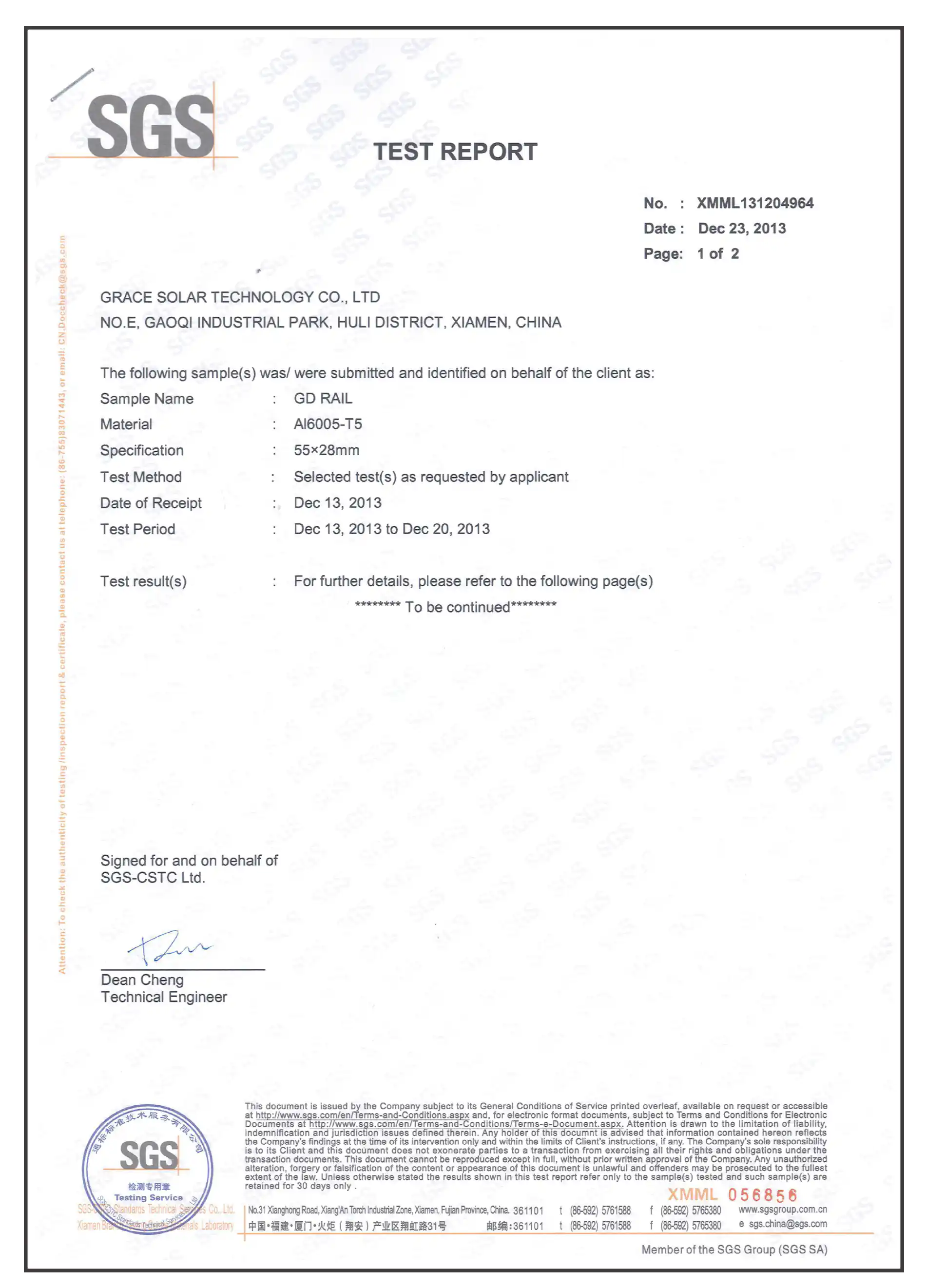

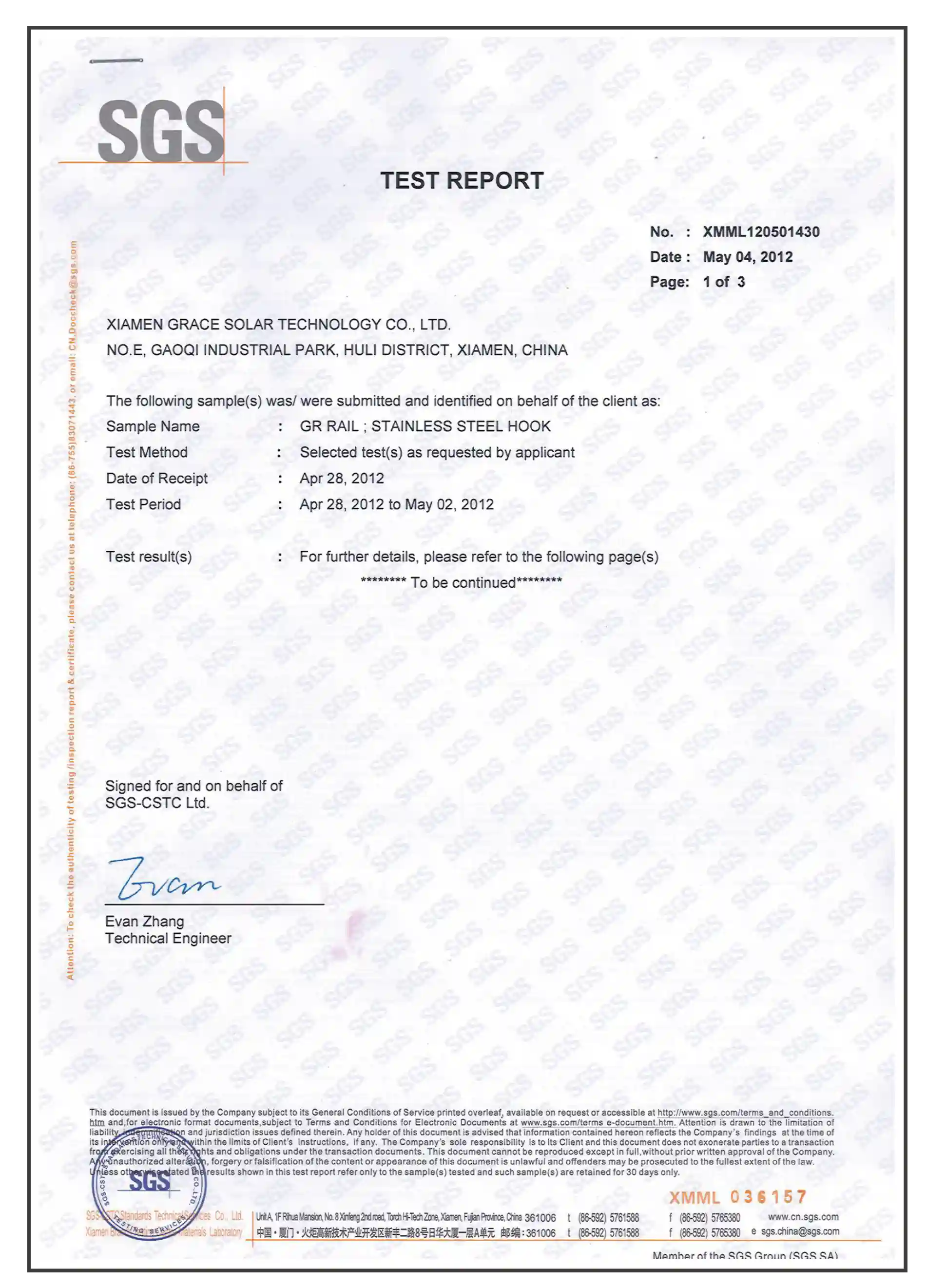

Global Certifications

15-year expertise | Validated in 100+ countries. Full compliance with ISO 9001/14001/45001, CE/TUV/JIS/UL, Australian CEC, and wind tunnel tests, ensuring seamless market access from Asia to EMEA.

/ZAM-coated%20steel%20components%20for%20corrosion-resistant%20solar%20racking_-600x400h.webp)

/Double-column%20aluminum%20solar%20ground%20mounting%20system%20for%20large-scale_-600x400h.webp)

/ZAM-coated%20steel%20components%20for%20corrosion-resistant%20solar%20racking_-80x80w.webp)

/Double-column%20aluminum%20solar%20ground%20mounting%20system%20for%20large-scale_-80x80w.webp)

_-800x600h.webp)

-800x600h.webp)

-800x600h.webp)

_-2480x3507.webp)

__1-1900x2643.webp)

_-2480x3507.webp)

_-2480x3507.webp)