Table of Contents

What Are Solar Flat Roof Mounts and How Do They Work?

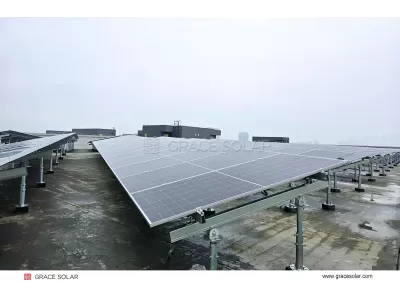

Solar flat roof mounts are specialized mounting systems designed specifically for installing solar panels on flat or low-slope roofs. Unlike traditional pitched roof systems, flat roof mounts must account for unique challenges including water drainage, wind uplift resistance, and weight distribution without compromising roof integrity.

These innovative systems have revolutionized solar installation on commercial buildings, industrial facilities, and modern residential properties with flat roof designs. The fundamental principle involves elevating solar panels at an optimal angle to maximize energy production while ensuring structural safety and weatherproofing.

The Science Behind Flat Roof Solar Performance

Properly designed flat roof mounting systems leverage physics principles to maintain stability. Ballasted systems use calculated weight distribution to counter wind uplift forces, while engineered tilt angles optimize solar exposure throughout the day. The ideal tilt angle typically matches the location's latitude, though adjustable systems offer seasonal optimization.

Types of Flat Roof Mounting Systems

Understanding the different types of flat roof mounting systems is crucial for selecting the right solution for your specific project requirements and roof conditions.

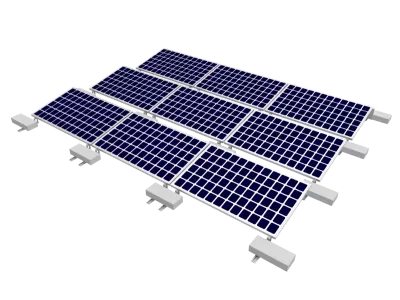

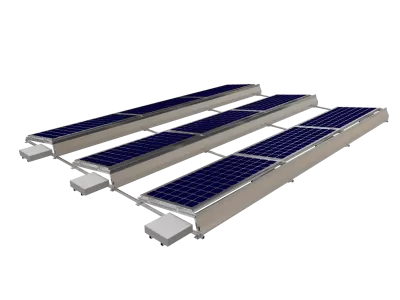

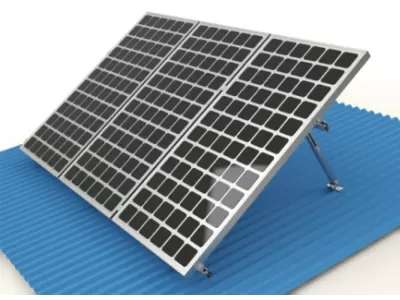

Ballasted (Non-Penetrating) Systems

Ballasted systems represent the most popular choice for commercial flat roof installations. These systems use carefully calculated weights, typically concrete blocks or specialized ballast trays, to secure the solar array without roof penetrations. The weight distribution is engineered to withstand local wind and snow loads while maintaining roof warranty compliance.

Major advantages include zero roof penetration, preservation of existing roof warranties, and typically faster installation times. These systems are ideal for large commercial roofs with adequate load-bearing capacity.

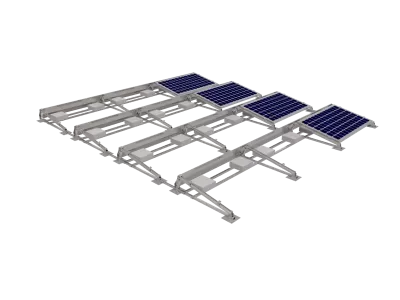

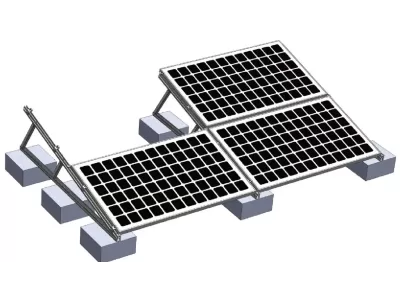

Hybrid Ballasted Systems

Hybrid systems combine ballasted design with minimal strategic attachments for enhanced stability in high-wind regions. This approach reduces overall ballast weight while providing additional security through limited, properly flashed roof penetrations.

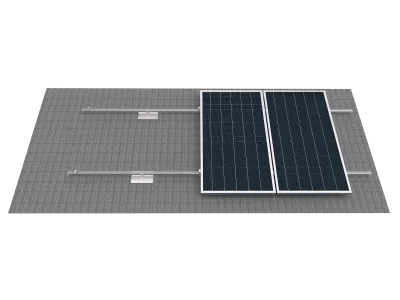

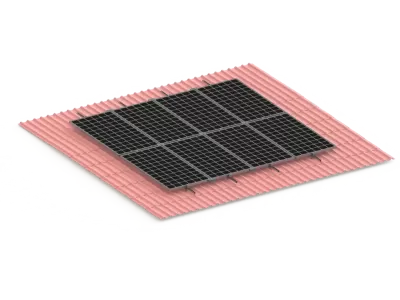

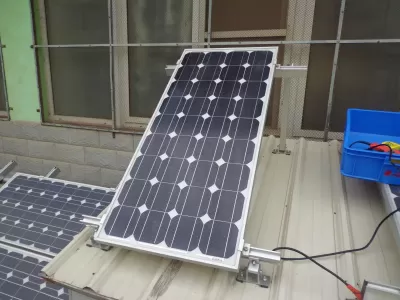

Penetrating (Attached) Systems

While less common for pure flat roofs, penetrating systems use structural attachments through the roof membrane into the building's framework. These require professional flashing and sealing to maintain waterproof integrity and may affect roof warranties.

Advantages of Ballasted Flat Roof Systems

Ballasted solar mounting systems offer numerous benefits that make them the preferred choice for many commercial and residential flat roof applications.

Roof Integrity Preservation

By eliminating roof penetrations, ballasted systems completely preserve the existing roof membrane and maintain manufacturer warranties. This is particularly valuable for newer buildings with transferable warranties.

Faster Installation & Lower Costs

Non-penetrating systems typically install faster than their penetrating counterparts, reducing labor costs and project timelines. The simplified installation process also minimizes potential installation errors.

Adjustability and Flexibility

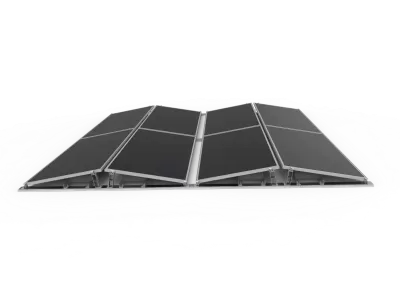

Modern ballasted systems offer adjustable tilt angles from 5° to 15°, allowing optimization for seasonal sun angles and geographic location. This flexibility maximizes energy production without structural compromises.

Key Considerations for Flat Roof Solar Installation

Successful flat roof solar projects require careful planning and consideration of several critical factors to ensure optimal performance and longevity.

Structural Load Capacity

The single most important consideration is the roof's structural capacity to support both the dead load (system weight) and live loads (snow, maintenance). Professional structural analysis is essential before proceeding with any flat roof solar installation.

Wind Load Calculations

Proper engineering must account for local wind patterns and building height. Ballast requirements vary significantly based on geographic location, building exposure, and array configuration.

Roof Access and Maintenance

Consider future roof maintenance needs, HVAC equipment access, and drainage patterns. Proper system design should accommodate these requirements without compromising solar production.

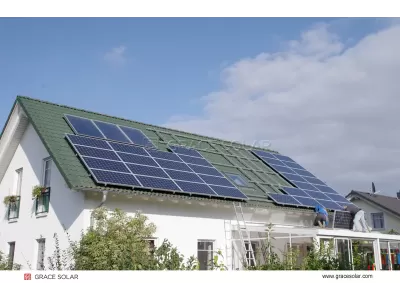

Grace Solar Flat Roof Mounting Solutions

With over a decade of expertise and ranking among the top 5 global market share leaders in solar mounting systems, Grace Solar brings unparalleled experience to flat roof solar installations. Our global cumulative installed capacity of 48GW demonstrates our proven track record across diverse projects worldwide.

Engineered for Excellence

Grace Solar's flat roof mounting systems incorporate advanced engineering principles developed through hundreds of MW of successful installations across more than 100 countries. Our systems are wind tunnel tested and certified to meet international standards including UL, TUV, CE, and JIS.

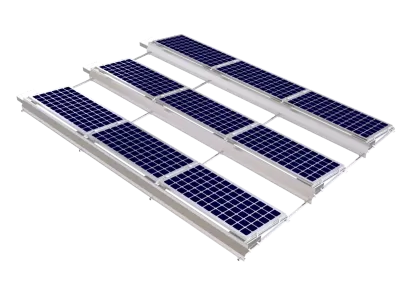

Innovative Product Features

Our flat roof solutions feature adjustable tilt angles from 5° to 15°, corrosion-resistant aluminum construction, and precision-engineered ballast calculations. The modular design allows for rapid installation and easy maintenance access while maintaining optimal energy production.

Adhering to our core value of "Do it right the first time," every Grace Solar flat roof system undergoes rigorous quality control and testing to ensure long-term reliability and performance in diverse environmental conditions.

Flat Roof Mount Installation Process

Professional installation of flat roof mounting systems follows a systematic approach to ensure safety, efficiency, and optimal performance.

Site Assessment and Planning

The process begins with comprehensive site evaluation including structural analysis, roof condition assessment, and shading analysis. This phase determines optimal array placement and system configuration.

Ballast Calculation and Layout

Using project-specific wind and snow load data, engineers calculate required ballast weight and distribution. The layout is optimized for both energy production and structural safety.

Modular Installation

Grace Solar's pre-engineered components enable efficient modular installation. The process typically involves positioning ballast trays, assembling support structures, mounting panels, and final system adjustments.

Roof Surface Compatibility

Flat roof mounting systems must be compatible with various roofing materials commonly found in commercial and residential applications.

Membrane Roofs (EPDM, TPO, PVC)

Ballasted systems are ideal for single-ply membrane roofs, providing secure mounting without compromising the waterproof membrane. Proper protection mats prevent abrasion and damage.

Built-Up Roofing (BUR) and Modified Bitumen

These traditional roofing materials work well with both ballasted and hybrid systems. Additional considerations include surface protection and drainage maintenance.

Metal Standing Seam Roofs

While technically pitched, low-slope metal roofs often use specialized flat roof-style systems with seam attachments or weighted solutions for minimal slope applications.

Professional Flat Roof Solar Solutions

As a global leader with proven expertise across diverse markets, Grace Solar provides comprehensive flat roof mounting solutions backed by international certifications and extensive project experience. Our systems are engineered for reliability, efficiency, and long-term performance.

With the solar industry evolving rapidly, trust Grace Solar's innovative approach and commitment to quality for your next flat roof solar project. Contact us to learn how our mounting solutions can optimize your solar investment while protecting your roof integrity.