Table of Contents

- Introduction: The Kumamoto Energy Milestone

- Vertical Beam Innovation: Solving Mountain Challenges

- The Aluminum Alloy Advantage: Lightweight & Durable

- Policy Support & Economic Impact

- GRS Expertise: The Force Behind the Project

- Engineering the Future with Technology

Introduction: The Kumamoto Energy Milestone

In the heart of Kyushu Island, Japan, Kumamoto Prefecture is witnessing a significant energy revolution. As the global photovoltaic industry pivots towards lightweight and highly adaptable solutions, GRS (Grace Solar) has introduced an innovative "vertical beam horizontal placement" aluminum alloy ground-mounted support system. In this typhoon-prone region, a groundbreaking 17.17MW green energy array now stands, marking a strategic stronghold in Japan's ambitious renewable energy landscape and showcasing the pinnacle of mountain solar engineering.

Vertical Beam Innovation: Solving Mountain Challenges

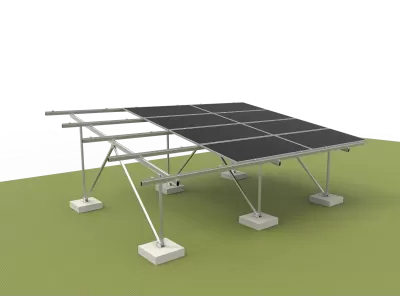

Kumamoto's terrain presents an extreme challenge for photovoltaic development: rolling hills with an average slope of 30%, a humid climate with heavy annual rainfall increasing metal corrosion risks, and frequent typhoons during summer and autumn that test structural integrity. Traditional steel supports face critical shortcomings here—high corrosion risk, difficult precision control on slopes, elevated maintenance costs, and low installation efficiency.

The Modular "Lego" Solution

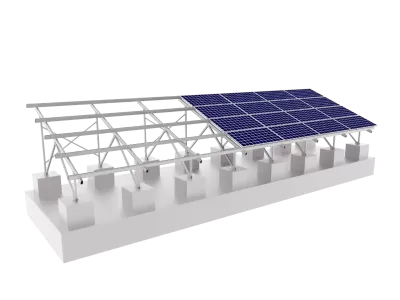

Grace Solar's R&D team innovated with a longitudinal main beam horizontal placement scheme, creating a fully modularized support system. This design, akin to precision-assembled "Lego blocks," provides a tailored solution for complex mountainous terrains. Each unit uses pre-assembled aluminum alloy components, which significantly enhances wind load resistance, shortens installation cycles, and perfectly adapts to the fragmented plots typical of mountainous areas. This approach underscores our core value: Do it right the first time.

The Aluminum Alloy Advantage: Lightweight & Durable

The project employs 6005-T5 aviation-grade aluminum alloy, achieving an exceptional lightweight profile of 1.8kg per square meter—a 65% weight reduction compared to traditional steel. A special anodizing process forms a robust 10μm protective layer, passing stringent JIS H8601 salt spray tests for a corrosion-resistant lifespan exceeding 30 years. In Kumamoto's acidic soil rich in Aso volcanic ash, the support system is equipped with invisible armor.

Triple-Benefit Disruption

This "flexible yet strong" characteristic delivers disruptive value:

- Eco-friendly: Eliminates galvanizing pollution, reducing land restoration costs by 70%.

- Full-cycle Economics: 30-year maintenance-free design lowers the Levelized Cost of Energy (LCOE).

- Carbon Innovation: Reduces carbon emissions by 48 tons from raw materials to installation.

The system has received dual certifications from JPEA and JIS, a testament to the rigorous quality standards upheld in our 2000m² Experiment Center.

Policy Support & Economic Impact

Driven by Japan's target of 36-38% renewable energy by 2030, the Kumamoto project benefits from powerful policy incentives. The Ministry of Economy, Trade, and Industry (METI) listed it as a key demonstration project, providing significant subsidies for infrastructure and technology innovation.

Catalyst for Local Growth

The project has spurred substantial local development: creating 320 direct jobs during construction and 45 long-term operational positions. It has attracted supporting enterprises, forming a new energy industrial cluster. Kumamoto plans to use this as a model to promote 200MW of similar projects within five years, aiming to build Kyushu's largest mountain solar base.

GRS Expertise: The Force Behind the Project

This milestone was achieved by Xiamen Grace Solar New Energy Technology Co., Ltd., a global leader and a trustworthy brand for smart solar mounting systems. With over a decade of rapid development, Grace Solar ranks among the top 5 globally in market share and holds the top 1 position in the Japanese market.

Our credentials are built on scale and reliability: Global cumulative installed capacity of 48GW, annual production capacity of 15GW from our 110,000m² factory area, and hundreds of MW projects successfully installed in over 100 countries. Backed by a BYMEA Group with a registered capital of 500 Million and a team of 650 highly sophisticated engineers, we integrate AI, IoT, and intelligent manufacturing into our solutions like the GS-Smart ground mounting system used in Kumamoto.

Holding over 100 patents and certifications worldwide (UL, TUV, JIS, etc.), and with long-term partnerships with global Top 500 companies, we live our mission: "Mount every solar plant firm as rock, bring more profits from the sun." We invite you to contact us to discuss custom solar mounting solutions for your next project.

Engineering the Future with Technology

The Kumamoto project's modular connectors enable zero-welding, all-bolt assembly, with installation precision controlled within ±5mm. Joint tests with the University of Tokyo confirmed its dynamic load-bearing capacity at 1.5 times the JIS C8955 standard, a resilience proven during Kyushu's seismic events.

In this quiet energy revolution, the relationship between humans and the land is being redefined. The success of the Kumamoto project is not just a technological breakthrough but a profound practice in sustainable development, rooted in our enterprise roots of providing the "Most trustworthy products and service."

Looking ahead, Grace Solar is committed to bringing the "Kumamoto Model" to broader lands, allowing green energy seeds to take root worldwide. With technological innovation as the pen and sustainable development as the ink, we are drawing a new blueprint for the renewable energy revolution, steadfast in our vision to "Bring Grace Solar to all homes."

/N-Type%20Aluminum%20Solar%20Ground%20Mounting%20System%20with%20Adjustable%20Tilt-400x300w.webp)

/Residential%20Ground%20Mount%20System%20with%200-60°%20Tilt%20Adjustment-400x300w.webp)

/Adjustable%20solar%20ground%20mount%20system%20on%20snowy%20mountain%20with%2055%20Angle%20tilt_-400x300w.webp)

/Engineer%20assembling%20Grace%20Solar's%20portrait%20ground%20mount%20in%20typhoon%20area_-400x300w.webp)