In the global wave of energy transition, solar energy has become the preferred choice for many enterprises to achieve green development due to its clean and sustainable characteristics. As the "skeleton" of the solar power generation system, the solar mounting system bears the mission of supporting solar panels and ensuring their stable operation.

In recent years, solar mounting technology has continuously innovated, and products on the market are dazzling. How to choose a solar mounting system is a key challenge for many solar system installation users. Choosing the right mounting system relates to system operation efficiency, cost and benefits, while choosing the wrong one can lead to continuous troubles. Next, this article will analyze the selection points from the dimensions of cost-effectiveness, compatibility, material, installation, and after-sales service, helping you avoid pitfalls, choose suitable products, and start your green energy journey.

Figure 1: Large-scale ground solar mounting system installation showcasing robust structural support.

Table of Contents

Solar Mounting Basic Information

Definition and Function

Solar mounting systems, also known as photovoltaic mounts, are structural systems used to fix solar panels. Their main function is to install solar panels at the optimal angle and orientation, ensuring they fully receive sunlight, thereby improving solar conversion efficiency and delivering green power continuously to enterprises.

Common Installation Locations

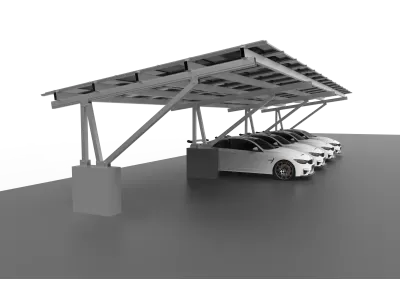

Common installation locations for solar mounts are roofs and ground. Roof installation is suitable for various commercial and industrial buildings, making full use of idle space and reducing land occupancy; ground installation is more suitable for large-scale solar power plant projects, allowing flexible layout based on terrain and light conditions.

Cost Proportion and Price Influencing Factors

In the total cost of a solar installation system, photovoltaic mounts typically account for about 10% - 15%. Their price is influenced by various factors, such as mount type, material, production process, market supply and demand, and labor costs in the installation region.

The most common module installation technology uses solar panel mounting brackets, securely connecting the mounts to solar panels and base structures through bolts, welding, etc. Mount materials mainly include carbon steel, aluminum alloy, and stainless steel, each with different performance characteristics and application scenarios, playing a decisive role in quality and service life.

Cost and Benefits

Initial Procurement Cost

When choosing solar mounts, the initial procurement cost is an important consideration for enterprises. Prices vary significantly based on material and type. Generally, steel mounts are relatively low-cost but may have higher later maintenance costs; aluminum alloy mounts are slightly more expensive but offer advantages like light weight and corrosion resistance, with lower later maintenance costs.

Long-term Returns

Beyond initial cost, the long-term returns of solar mounts cannot be ignored. High-quality mounts ensure stable operation of solar panels throughout their lifecycle, improving power generation efficiency and bringing higher economic benefits. Some mounts with advanced design and优质 materials can increase solar panel efficiency by 5% - 15%, significantly boosting long-term returns.

Types of Mounting Systems Adapted to Different Terrains

Roof Mounting Systems

Roof mounts are suitable for various commercial, industrial, and residential roofs. Based on roof material and structure, they can be divided into flat roof mounts and sloped roof mounts. Flat roof mounts typically use ballasted or anchored installation,No need roof penetration, minimizing structural damage; sloped roof mounts require custom design based on roof slope and orientation to ensure optimal light conditions for solar panels.

Figure 2: Residential roof solar panel installation with secure mounting.

Figure 3: Commercial flat roof solar mounting system with ballasted design.

Figure 4: Sloped roof solar panel mounting with custom brackets.

Figure 5: Industrial roof solar mounting array for large-scale energy generation.

Ground Mounting Systems

Ground mounts are suitable for large-scale solar power plant projects. Based on terrain and geological conditions, they can be fixed mounts or tracking mounts. Fixed mounts have simple structure and low cost, suitable for flat areas with uniform light conditions; tracking mounts adjust solar panel angles in real-time based on sun position, improving efficiency, but at higher cost, suitable for areas with abundant light resources and lower land costs.

Figure 6: Ground mount rear view with worker conducting quality inspection.

Figure 7: Ground mount rear view showing robust structural details.

Figure 8: Single-axis solar tracker mounting system for enhanced energy yield.

Price and Later Maintenance Costs of Different Materials

Carbon Steel Material

Carbon steel mounts have high strength and load-bearing capacity, with relatively low prices. However, steel is prone to rust and requires anti-corrosion treatment, leading to higher later maintenance costs. Compared to aluminum alloy and stainless steel, carbon steel mounts offer cost advantages and are widely used in large commercial ground photovoltaic plants. Anti-corrosion treatment costs about 10% - 15% of total cost, and steel mounts need regular maintenance.

Grace Solar's Neng Hui - ground fixed mounting system uses carbon steel material. To address rust issues, Grace Solar employs anti-corrosion treatments like hot-dip galvanizing or magnesium-aluminum-zinc plating, greatly extending service life. For more information, visit: Grace Solar Official Website - Neng Hui - Ground Fixed Mounting System.

Aluminum Alloy Material

Aluminum alloy mounts are light weight, corrosion-resistant, aesthetically pleasing, and have low later maintenance costs. However, aluminum alloy is relatively more expensive, suitable for projects with high weight and appearance requirements. They have long service life and generally require only regular cleaning.

Grace Solar's Neng She - roof mounting system includes products using aluminum alloy material. These mounts reduce installation difficulty, offer excellent corrosion resistance, and are aesthetically pleasing, suitable for commercial or residential roof solar systems. For details, visit: Grace Solar Official Website - Neng She - Roof Mounting System.

Stainless Steel Material

Stainless steel mounts offer excellent corrosion resistance and aesthetics, suitable for harsh environments. However, stainless steel is more expensive and harder to process. Later maintenance costs are low, but initial investment is higher due to price.

Grace Solar's L-foot hook kit uses stainless steel material, designed for projects requiring high corrosion resistance and aesthetics. Stainless steel is durable and fits various architectural styles. For related products and cases, browse: Grace Solar Official Website.

Figure 9: High-quality clamps and bolts for secure panel attachment.

Figure 10: Precision-engineered rail and connector for easy installation.

Installation Services

Installation Survey

The Grace Solar team uses satellite maps to survey project sites, understanding local terrain and customizing solar system installation plans. Tailored designs ensure optimal layout and angles for maximum solar reception efficiency.

Click here to input your information and get a customized solar system design plan.

Installation Efficiency

Fast and efficient installation services shorten project timelines and reduce investment costs. Choosing suppliers with rich experience and efficient teams ensures timely completion. Professional teams can complete large-scale mount installation quickly, accelerating project progress.

Installation Quality

Installation quality directly affects mount performance and service life. Enterprises should require detailed installation plans and quality assurance measures. Construction must follow industry standards to ensure precision and stability.

After-sales Service

Maintenance Response Speed

Timely maintenance response reduces downtime and losses when issues arise. Choosing suppliers with complete after-sales systems and quick response mechanisms is crucial. Some suppliers respond within 24 hours and dispatch teams promptly.

Warranty Period

A longer warranty period provides peace of mind. Generally, high-quality solar mount products offer warranties of 5 - 10 years. Suppliers should handle repairs and replacements for quality issues during this period.

Grace Solar offers a warranty period of up to 10 years, with certifications like ISO9001, ISO45001, ISO14001, and rigorous tests including pull tests, salt spray tests, wind tunnel tests, and load tests. These ensure mount longevity and stability in extreme weather and disaster conditions.

Figure 11: Grace Solar's international certifications and quality standards ensuring product reliability.

Brand Recommendation and Product Introduction

Among many solar mounting brands, Grace Solar stands out as a trustworthy choice for enterprises. After 17 years of rapid development, Grace Solar's photovoltaic mounting products rank among the top 5 in global market share, with the top 1 share in the Japanese market. The global cumulative installed capacity is 48GW, with an annual production capacity of 15GW. Hundreds of MW projects have been successfully installed in over 100 countries and regions including Japan, the United States, Australia, Europe, the Middle East, Africa, and Southeast Asia.

Grace Solar integrates new technologies such as AI artificial intelligence, Internet of Things, energy storage, energy Internet, and intelligent manufacturing, and has launched the GS-Light intelligent tracking system, GS-Smart ground mounting system, and GS-Energy roof mounting system, with over 100 patents. It is one of the few Chinese brands that can provide complete installation solutions in the DSP and CSP markets.

Grace Solar has a team of highly sophisticated engineers and a fully equipped key laboratory. Products have passed global certifications including UL, TUV, CE, JIS, MCS, AS/NZS1170, Wind Tunnel Test Report, and bankability reports for the GS-light Tracker. Grace Solar has established long-term strategic partnerships with many Top 500 companies globally.

Grace Solar adheres to the brand spirit of "Born from renewable energy, drives solar forward", based on the energy industry, and constantly explores ahead with the original intention of Chinese manufacturing and global strategy. Bring Grace Solar to all homes!

Enterprise Vision: Bring Grace Solar to all homes

Enterprise Mission: Mount every solar plant firm as rock, bring more profits from the sun

Enterprise Core Value: Do it right the first time

Enterprise Roots: Most trustworthy products and service, Best stage for hard workers achieve glorious goal, Fastest payback and most stable growth brand for investors

For more about Grace Solar, visit Grace Solar company introduction.

In summary, when choosing a solar mounting system, consider cost-effectiveness, compatibility, installation services, and after-sales support. Grace Solar, with excellent product quality, innovative technology, and complete services, provides one-stop solutions. To learn more or get detailed quotes, visit Grace Solar's official website or contact us to start your green energy journey.

/Aluminum%20alloy%20solar%20ground%20mount%20system%20for%20residential%20solar%20panels-400x300w.webp)

/Modular%20ground-mounted%20solar%20structure%20with%20corrosion-resistant%20coating-400x300w.webp)

/W-Type%20aluminum%20solar%20mounting%20system%20structural%20detail-400x300w.webp)

/Ground%20screw%20foundation%20installation%20for%20Grace%20Solar%20racking-400x300w.webp)

/Adjustable%20solar%20ground%20mount%20system%20on%20snowy%20mountain%20with%2055%20Angle%20tilt_-400x300w.webp)

/Engineer%20assembling%20Grace%20Solar's%20portrait%20ground%20mount%20in%20typhoon%20area_-400x300w.webp)

/ZAM-coated%20steel%20components%20for%20corrosion-resistant%20solar%20racking_-400x300w.webp)

/Double-column%20aluminum%20solar%20ground%20mounting%20system%20for%20large-scale_-400x300w.webp)

/Al-Zn-Mg%20coated%20piling%20structure%20for%20extreme%20weather%20resistance_-400x300w.webp)

/Double-column%20carbon%20steel%20solar%20ground%20mount%20system%20with%20portrait%20panel%20arrang_-400x300w.webp)

/Aluminum%20alloy%20solar%20ground%20mount%20system%20installation%20on%20residential%20property_-400x300w.webp)

/Close-up%20of%20anodized%20aluminum%20clamp%20connection%20in%20ground%20mounting%20system_-400x300w.webp)

/Aluminum%20Alloy%20Solar%20Panel%20Ground%20Mount%20Frame_-400x300w.webp)

/Adjustable%20Tilt%20Ground%20Mount%20Solar%20Racking%20System_-400x300w.webp)

/Grace%20Solar%20ground%20mount%20installation%20on%20concrete%20foundation%20with%20rail%20clamps_-400x300w.webp)

/Aluminum%20alloy%20solar%20ground%20mounting%20system%20portrait%20placement%20for%20495W%20panels_-400x300w.webp)