Industry Encyclopedia | Solar Mounting Systems

How to Strategically Arrange PV Modules for Optimal Performance

The arrangement of solar modules on mounting structures is the critical backbone that determines a plant's power yield, land efficiency, and long-term operational stability. Explore the engineering principles behind successful layouts.

Table of Contents

The strategic placement of solar modules on mounting systems is a fundamental engineering decision that directly dictates the power generation efficiency, land utilization ratio, and long-term structural integrity of any photovoltaic power station. As a global leader in smart solar mounting solutions, Grace Solar integrates over a decade of project experience across 100+ countries into every system design. This guide explores the core principles of module orientation, array configuration, and component positioning, providing actionable insights to maximize the return on your solar investment.

Component Orientation

Module orientation forms the foundational layer of photovoltaic system design, primarily split into horizontal (landscape) and vertical (portrait) layouts. The horizontal arrangement, where the module's long edge is perpendicular to the north-south axis, creates a compact structure that minimizes material usage and is exceptionally compatible with single-axis and dual-axis tracking systems, leading to significant cost reductions. Conversely, the vertical layout, with the long side parallel to north-south, offers superior adaptability to narrow, irregular, or sloping terrains.

Selecting the optimal orientation requires a holistic analysis of site topography, chosen mounting system, and financial constraints. Leveraging insights from 48GW of cumulative global installations, Grace Solar's engineering team provides data-driven recommendations to ensure the chosen layout delivers peak performance in diverse environments, from the deserts of the Middle East to the rooftops of Europe.

Key Insight:

For utility-scale projects using trackers, horizontal layout can reduce mechanical complexity and balance system costs, a principle perfected in Grace Solar's GS-Light intelligent tracking system.

Horizontal vs. Vertical: A Quick Comparison

- Horizontal (Landscape): Ideal for tracker systems, reduces wind load, lowers BOS cost.

- Vertical (Portrait): Best for constrained land, easier cable management, reduced soiling in certain climates.

- Decision Factor: Always conduct a site-specific simulation. Grace Solar's 2000m² experiment center and engineering software suite provide precise yield forecasts for both options.

Array Layout

Planning the photovoltaic array is a meticulous exercise in balancing light capture with spatial economics. The number of rows along the north-south direction is critical and must be calculated based on the project's latitude, the sun's altitude angle throughout the year, and the permissible shading loss to avoid significant energy reduction. In regions like China, a common and optimized practice for horizontal arrays is a 4-row grouping, a standard born from years of optimizing the trade-off between energy yield and land cost.

The column count (east-west direction) defines the array's width. The goal is a dual-objective optimization: ensuring that on the winter solstice—the day with the longest shadows—the front row does not significantly shade the one behind, while simultaneously packing the maximum number of modules into the available area. With an annual production capacity of 15GW and hundreds of MW successfully deployed, Grace Solar utilizes advanced simulation tools to create bespoke array layouts that are both energy-dense and financially viable for every terrain.

Engineering Note:

Standard row-to-row spacing formulas provide a good start, but factors like local albedo (ground reflectivity) and micro-climate conditions can affect the optimal layout. Grace Solar's bankability reports and site-specific wind tunnel tests add a layer of financial and technical security to this critical design phase.

Precise Positioning

The final installation tilt angle and ground clearance are decisive parameters for system performance, safety, and longevity. The tilt angle is primarily set to maximize annual solar irradiance collection for a given location. However, in land-constrained or high-cost scenarios, a slightly reduced tilt can be adopted to increase module density and improve land use efficiency without a disproportionate yield penalty.

Ground clearance design embodies practical engineering wisdom. It must be sufficient to keep electrical components safe from ground floodwater during heavy rains, promote under-array airflow for natural module cooling (which boosts efficiency), and provide ample space for snow to slide off in colder climates. Every Grace Solar mounting system, from the GS-Smart ground mount to the GS-Energy roof system, is designed with these multi-faceted requirements in mind, backed by international certifications like UL, TUV, and JIS.

Tilt Angle

Optimized for local latitude. Adjustable systems from Grace Solar allow for seasonal tuning to capture more energy.

Ground Clearance

A critical factor for maintenance, cooling, and weather resilience. Designs are validated for specific site conditions.

Certification & Safety

All positioning strategies are underpinned by rigorous international standards and Grace Solar's 100+ patents.

Engineering Excellence by Grace Solar

48GW+

Global Cumulative Installed Capacity

100+

Countries with Successful Projects

Top 5

Global Market Share in Solar Mounting

650+

Dedicated Staff & Engineers

As a core member of the BYMEA Group and a leading force in smart solar mounting, Grace Solar integrates AI, IoT, and advanced manufacturing into its GS-Light Tracker, GS-Smart Ground Mount, and GS-Energy Roof systems. Our mission is to "Mount every solar plant firm as rock, bring more profits from the sun." With a fully equipped laboratory, global certifications, and partnerships with Fortune 500 companies, we turn complex site challenges into reliable, high-yield power plants.

Conclusion

The strategic arrangement of PV modules is the unsung hero of solar plant performance. It is an intricate blend of physics, engineering, and economics that forms the plant's "power generation lifeline." From the initial orientation choice to the final bolt tightened, each decision reverberates through the project's lifetime yield.

Partnering with an experienced mounting specialist like Grace Solar transforms this complexity into certainty. Guided by the principle "Do it right the first time," we deliver not just products, but optimized, bankable energy yield. Let our global experience and engineered solutions provide the stable, profitable foundation your next solar project requires.

Product Detail Gallery

See the engineering excellence of Grace Solar mounting systems up close.

Detail: Precision clamping for both landscape and portrait module orientations.

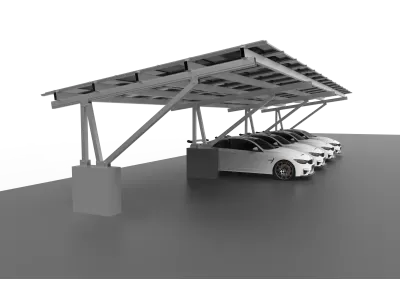

Overview: Engineered array layout maximizing land use and minimizing shading loss.

Technology: The drive unit of the AI-powered GS-Light tracker for optimal sun following.

/Aluminum%20alloy%20solar%20ground%20mount%20system%20for%20residential%20solar%20panels-400x300w.webp)

/Modular%20ground-mounted%20solar%20structure%20with%20corrosion-resistant%20coating-400x300w.webp)

/W-Type%20aluminum%20solar%20mounting%20system%20structural%20detail-400x300w.webp)

/Ground%20screw%20foundation%20installation%20for%20Grace%20Solar%20racking-400x300w.webp)

/Adjustable%20solar%20ground%20mount%20system%20on%20snowy%20mountain%20with%2055%20Angle%20tilt_-400x300w.webp)

/Engineer%20assembling%20Grace%20Solar's%20portrait%20ground%20mount%20in%20typhoon%20area_-400x300w.webp)

/ZAM-coated%20steel%20components%20for%20corrosion-resistant%20solar%20racking_-400x300w.webp)

/Double-column%20aluminum%20solar%20ground%20mounting%20system%20for%20large-scale_-400x300w.webp)

/Al-Zn-Mg%20coated%20piling%20structure%20for%20extreme%20weather%20resistance_-400x300w.webp)

/Double-column%20carbon%20steel%20solar%20ground%20mount%20system%20with%20portrait%20panel%20arrang_-400x300w.webp)

/Aluminum%20alloy%20solar%20ground%20mount%20system%20installation%20on%20residential%20property_-400x300w.webp)

/Close-up%20of%20anodized%20aluminum%20clamp%20connection%20in%20ground%20mounting%20system_-400x300w.webp)

/Aluminum%20Alloy%20Solar%20Panel%20Ground%20Mount%20Frame_-400x300w.webp)

/Adjustable%20Tilt%20Ground%20Mount%20Solar%20Racking%20System_-400x300w.webp)

/Grace%20Solar%20ground%20mount%20installation%20on%20concrete%20foundation%20with%20rail%20clamps_-400x300w.webp)

/Aluminum%20alloy%20solar%20ground%20mounting%20system%20portrait%20placement%20for%20495W%20panels_-400x300w.webp)