Table of Contents

- From Field Challenges: Innovating for Simplicity and Safety

- "Listening" Drives Process Upgrades

- Returning to User Logic: When Simplification Meets Reality

- Grace Solar's Commitment: Beyond Mounting Systems

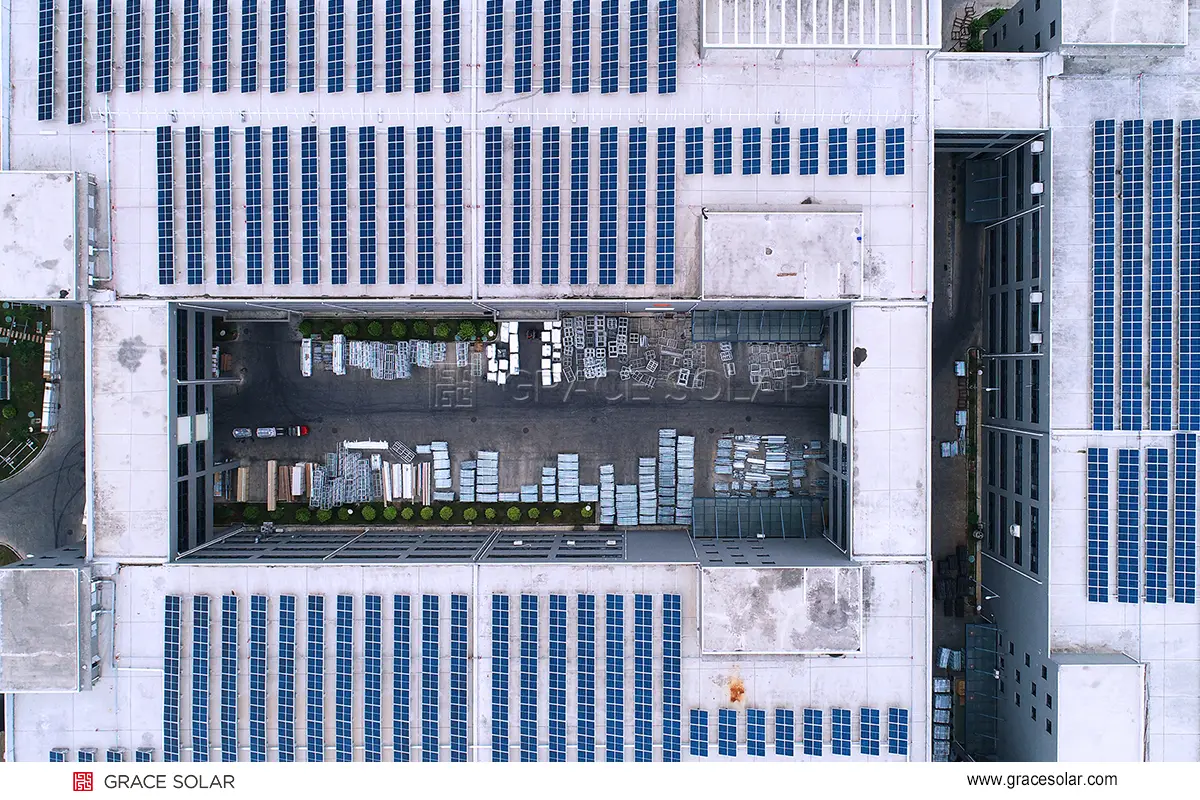

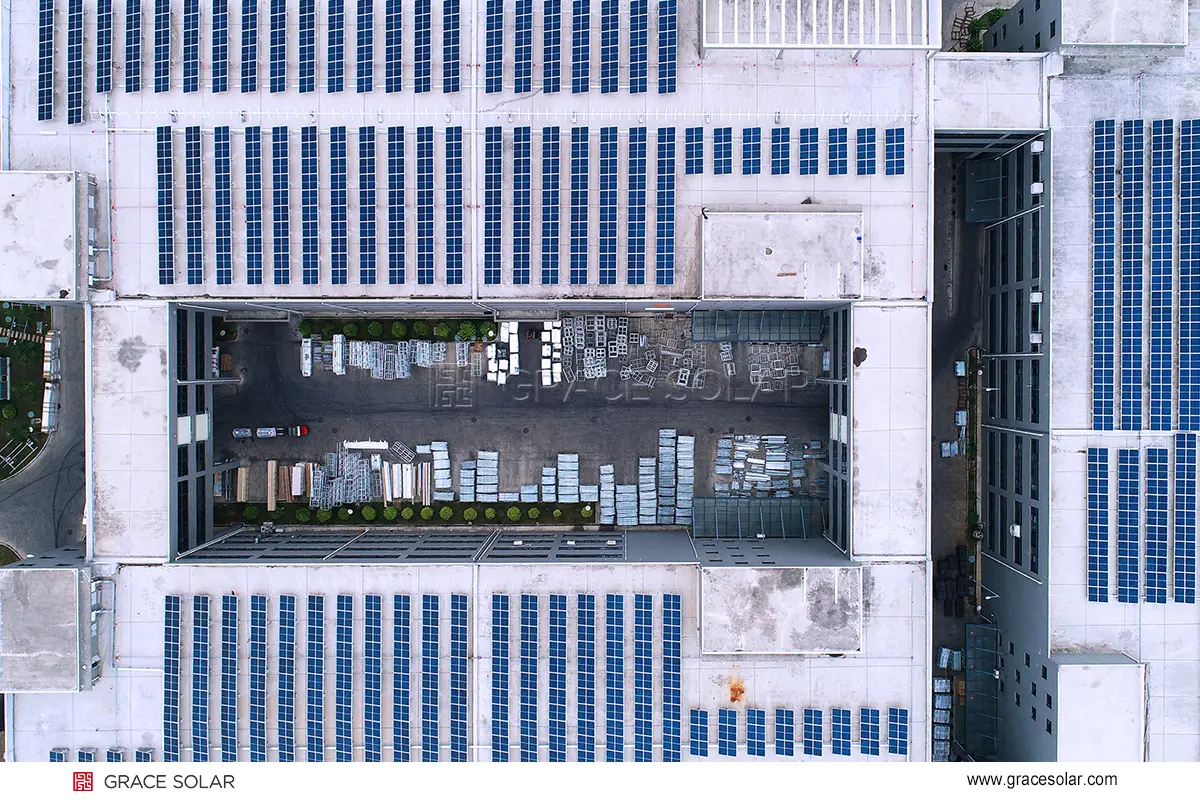

In the wave of global energy transition, solar power plants are becoming a green electricity source for more and more regions. However, complex geographical environments and differentiated construction conditions remain challenges faced by the industry. As a technology-driven leader deeply engaged in the solar mounting field, Grace Solar always takes real on-site needs as the origin of research and development, continuously seeking optimal solutions in structural design, process iteration, and scenario adaptation. Backed by the BYMEA Group with a registered capital of 500 million, over 650 staff, and a factory area of 110,000 m², Grace Solar ranks among the top 5 in global market share and top 1 in the Japanese market, with a cumulative installed capacity of 48GW and annual production capacity of 15GW. Our products have been successfully deployed in hundreds of MW projects across more than 100 countries and regions, including Japan, the United States, Australia, Europe, the Middle East, Africa, and Southeast Asia, demonstrating our global reach and reliability.

From Field Challenges: Innovating for Simplicity and Safety

In overseas solar projects, scattered sites, varying construction levels, and frequent extreme weather are common. Installation convenience affects project cycles and costs, while structural rigidity determines whether a power plant can operate safely for decades under harsh loads like strong winds and snow. Grace Solar's extensive experience in diverse terrains—from deserts to coastal areas—has fueled our commitment to developing robust solutions that withstand these challenges without compromising efficiency.

The Single Column Structure System

To address this, the Grace Solar R&D team developed a single column structure system. This design significantly reduces the number of components and assembly steps, achieving deployment effects that require "no welding, no large machinery, and rapid setup with few personnel," making it especially suitable for remote areas with weak infrastructure. This is not just a structural solution but a systematic response logic. With over 100 patents and certifications like UL, TUV, CE, JIS, MCS, and AS/NZS1170, Grace Solar ensures reliability across diverse projects. For instance, in a recent project in Australia, this system reduced installation time by 30% compared to traditional methods, showcasing our focus on practicality and cost-effectiveness.

Dynamic test: Grace Solar systems undergo stringent wind and mechanical load simulations to ensure decades of field reliability.

"Listening" Drives Process Upgrades

Whether a product is truly "friendly" is ultimately defined by frontline installers. In numerous distributed and ground-mounted power plant projects, the Grace Solar team continuously collected on-site feedback, finding that traditional bolt connections are inefficient in high-altitude work and prone to "false tightening" due to uneven manual torque, posing long-term safety risks. Our engineers often conduct site visits to observe installations firsthand, ensuring that every design tweak addresses real-world pain points.

Electric Riveting Integration

These voices directly drove important upgrades in product connection processes: shifting from manual bolts to an electric riveting integration solution. The new design allows a single person to achieve uniform locking, improving installation efficiency by up to 40%, eliminating human error, and reducing the intensity and risks of high-altitude work. Every process iteration begins with listening to on-site voices, reflecting Grace Solar's core value of "Do it right the first time." This upgrade has been praised by installers in regions like the Middle East, where high temperatures and challenging conditions demand reliable and user-friendly tools.

Returning to User Logic: When Simplification Meets Reality

Innovation is not always about "reducing" in one direction. In mountainous solar project development, Grace Solar once tried to introduce an "angle-adaptive rotating component between structures," intending to adapt to various slopes with a single part and reduce part categories and inventory pressure. However, pilot projects in regions like Japan and Europe quickly reported that this component actually made steps cumbersome and operation laborious in practice, highlighting the gap between lab design and field execution.

Dynamic test: Corrosion and cyclic load testing validates the long-term durability of materials and connections.

Standardized Multi-Angle Connectors

The R&D team promptly delved into the site, finding that this "laboratory-feasible" design failed to address operational difficulties and personnel burdens in mountainous environments. Simplification should point to "reducing on-site operational complexity," not just reducing material types. The team decisively paused promoting this solution, returning to the long-verified multi-angle standardized connector system for more controllable construction. This user-centric approach aligns with Grace Solar's mission to "mount every solar plant firm as rock, bring more profits from the sun," and has led to successful deployments in complex terrains, such as hillside projects in Southeast Asia where stability and ease of use are paramount.

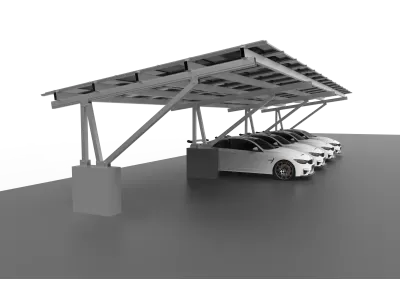

Grace Solar's Commitment: Beyond Mounting Systems

We provide not just mounting systems but executable, reliable, and sustainable energy construction support. Behind every power plant is Grace Solar's deep understanding and systematic response to natural environments and construction realities. Integrating technologies like AI, IoT, and energy storage, we offer comprehensive solutions through products like the GS-Light intelligent tracking system, GS-Smart ground mounting system, and GS-Energy roof mounting system. Guided by the brand spirit of "Born from renewable energy, drives solar forward," we aim to bring Grace Solar to all homes, supported by a fully equipped key laboratory and strategic partnerships with global Top 500 companies. Our vision is to make solar energy accessible and efficient worldwide, and our roots focus on delivering the most trustworthy products and services while creating the best stage for hard workers to achieve glorious goals.

For custom solar mounting and related products, contact us to discuss your needs. Explore more about our journey and innovations on our company profile page.

/Aluminum%20alloy%20solar%20ground%20mount%20system%20for%20residential%20solar%20panels-400x300w.webp)

/Modular%20ground-mounted%20solar%20structure%20with%20corrosion-resistant%20coating-400x300w.webp)

/W-Type%20aluminum%20solar%20mounting%20system%20structural%20detail-400x300w.webp)

/Ground%20screw%20foundation%20installation%20for%20Grace%20Solar%20racking-400x300w.webp)

/Adjustable%20solar%20ground%20mount%20system%20on%20snowy%20mountain%20with%2055%20Angle%20tilt_-400x300w.webp)

/Engineer%20assembling%20Grace%20Solar's%20portrait%20ground%20mount%20in%20typhoon%20area_-400x300w.webp)

/ZAM-coated%20steel%20components%20for%20corrosion-resistant%20solar%20racking_-400x300w.webp)

/Double-column%20aluminum%20solar%20ground%20mounting%20system%20for%20large-scale_-400x300w.webp)

/Al-Zn-Mg%20coated%20piling%20structure%20for%20extreme%20weather%20resistance_-400x300w.webp)

/Double-column%20carbon%20steel%20solar%20ground%20mount%20system%20with%20portrait%20panel%20arrang_-400x300w.webp)

/Aluminum%20alloy%20solar%20ground%20mount%20system%20installation%20on%20residential%20property_-400x300w.webp)

/Close-up%20of%20anodized%20aluminum%20clamp%20connection%20in%20ground%20mounting%20system_-400x300w.webp)

/Aluminum%20Alloy%20Solar%20Panel%20Ground%20Mount%20Frame_-400x300w.webp)

/Adjustable%20Tilt%20Ground%20Mount%20Solar%20Racking%20System_-400x300w.webp)

/Grace%20Solar%20ground%20mount%20installation%20on%20concrete%20foundation%20with%20rail%20clamps_-400x300w.webp)

/Aluminum%20alloy%20solar%20ground%20mounting%20system%20portrait%20placement%20for%20495W%20panels_-400x300w.webp)